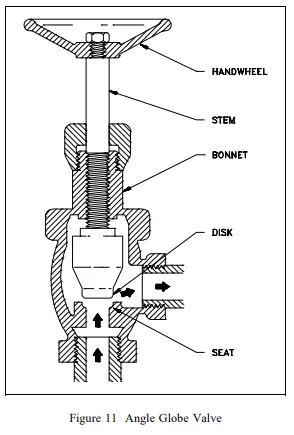

Angle Valve Design

The angle body globe valve design, illustrated in Figure 11, is a simple modification of the basic globe valve. Having ends at right angles, the diaphragm can be a simple flat plate. Fluid is able to flow through with only a single 90° turn and discharge downward more symmetrically than the discharge from an ordinary globe. A particular advantage of the angle body design is that it can function as both a valve and a piping elbow. For moderate conditions of pressure, temperature, and flow, the angle valve closely resembles the ordinary globe. The angle valve's discharge conditions are favorable with respect to fluid dynamics and erosion.

Globe Valve Disks

Most globe valves use one of three basic disk designs: the ball disk, the composition disk, and the plug disk.

Ball Disk

The ball disk fits on a tapered, flat-surfaced seat. The ball disk design is used primarily in relatively low pressure and low temperature systems. It is capable of throttling flow, but is primarily used to stop and start flow.

Composition Disk

The composition disk design uses a hard, nonmetallic insert ring on the disk. The insert ring creates a tighter closure. Composition disks are primarily used in steam and hot water applications. They resist erosion and are sufficiently resilient to close on solid particles without damaging the valve. Composition disks are replaceable.

Plug Disk

Because of its configuration, the plug disk provides better throttling than ball or composition designs. Plug disks are available in a variety of specific configurations. In general, they are all long and tapered.