Induction Motors and Alternators Explored

Electrical motors today have become a crucial part of our modern world. Today, the study and advancement of these devices have diversified like never before, creating huge opportunities for aspiring engineers. Some expert reading about AC/DC motors is presented here through many linked articles.

Everything You Wanted Know About AC Induction Motors

Motors are devices able to convert electrical energy to mechanical energy. Our industries primarily rely heavily on these devices, especially the AC motors. In fact, AC motors were probably the main machines that brought about the industrial revolution, without which even the modern world would feel completely handicapped. The subject and the concept of AC motors is rather complex and definitely needs a thorough and a comprehensive study.

The following links take you through a systematic learning course, beginning with the entire classification of AC motors, and proceeds with an elaborate discourse regarding various parameters associated with AC induction motors.

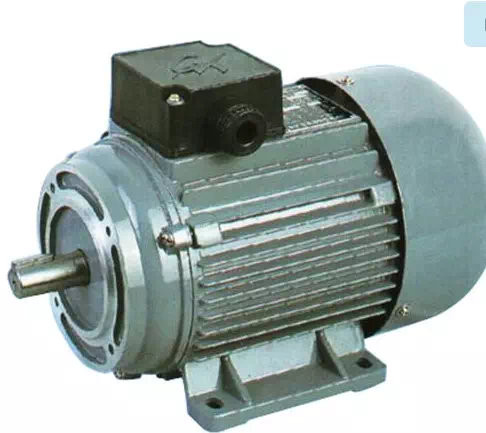

What are AC Induction Motors?

Basically an induction motor, also referred to as asynchronous motor, is a kind of AC motor in which the rotor acquires the power through the process of magnetic induction without incorporating slip rings. The main application of this category of motors can be seen in industrial drive mechanisms due to their more versatile operating principles.

Looking at Synchronous Motors

Unlike induction motors where the toque is acquired through the interaction of the induced current in the rotor and the rotating magnetic field, in synchronous motors it is achieved through the rotating magnetic fields from the stator enforced over the rotor. This results in a steady rate of rotation, and hence the name. Fundamentally, synchronous motors employ three types of rotors: squirrel cage rotors, slip ring rotors, and solid core rotors.

What's the Difference between Synchronous and Induction Motors

How Synchronous AC Motors Work

How to Start Synchronous Motors Smoothly Through Electronics

How Squirrel Cage Induction Motors Operate

Where is the Squirrel in the Motor?

How do Slip Ring Motors Function?

How do Slip Ring Motors Start?

Controlling Speed of Slip Ring Motors

How to Control Slip Ring Motor Speed

Other Forms of AC Motors

AC motors can be further classified into single phase motors, which may consist of magnetic repulsion motors widely used in locomotives, and other traction based engines. Our residential ceiling fans or the motors involving a capacitor start mechanism also come under AC motors.

How do Single Phase Motor Work?

How do Magnetic Repulsion Motors Work?

How do Universal Motors Work?

Controlling Speed in Universal Motors

How Capacitor Start Motors Work

How Shaded-Pole Single Phase Motors Work

Understanding AC Motor Speed Controllers and Conditioners

All mechanical devices must involve a control feature through which its force can be regulated as desired for the particular application. AC motors accommodate and incorporate this facility through various external electrical and electronic devices, especially designed for the purpose. Also since AC motor efficiency can be critical with the input frequency, they also require strict monitoring through respective devices.

Measuring Motor Speeds

The Effect of Frequency on AC Motors

How Variable Frequency Drive Units Work

How Dimmer Switches Work

How to Build a Dimmer Switch for controlling Ceiling Fans

DC Motors and Their Control Theory Explained

DC motors were once more popular than AC induction motors because of the ease with which their speed could be controlled. However, with the advent of modern electronics, AC motors today can be controlled as efficiently as their DC counterparts, making them the better favorites. Yet still, DC motors can be found applied widely in many different fields. Mainly DC motors are used for lighter applications, like in RC models, solar trackers, toys, computers hard drives, automotive actuators, CD/DVD player drives, etc.

Being smaller in size these motors have become the favorites with the hobbyists for making various robotic models. This has also led to the development of improved PWM controlled circuits for controlling these motors precisely as per the specs of the application.

Importantly DC motors are classified as brushed and brushless types, the latter being more efficient due to the involvement of a frictionless operating principle. A better view of these types of motors is explained through the following links along with a few interesting motor-control circuits that can be built at home:

How do DC Series Motors Work

How do Stepper Motors Work

How do Shunt-Wound DC Motors Work

Using electric Motors in Hybrid Vehicles

Simple DC Motor Control

An Oldie but a Goodie: GE Amplidyne Motor Generators

What is Back EMF in BLDC Motors?

How to Adjust Your PC Fan Speed

How to Make a DC Motor Speed Controller Using IC 556

How to Make a DC Motor Speed Controller Using Two 555 ICs

How to Control DC Motor Speed Using the IC L165

Two Large Generators

How Motors are Extensively Used for Generating Electricity

Very interestingly the definition of an electrical motor completely gets topsy turvy when these are employed or configured as electricity generators. The conversion of electrical energy into mechanical rotational energy through magnetic induction in the earlier mode now transforms and becomes responsible for generating electricity through the conversion of applied mechanical energy into electrical energy.

The device is popularly known as an alternator, since the generated electricity is in the form of AC or alternating current.

Here electricity is generated by rotating the rotor of the motor within a set of windings through external mechanical force. This mechanical force is normally extracted from wind power, hydro power, steam power, nuclear power, etc.

These devices today has become the primary source of power for the world, whether it's for lighting up the cities or the vehicles and the ships, alternators are used everywhere. A bicycle dynamo can be considered the best example of an alternator for studying purposes.

The articles linked below gives us a clear view of this magnificent electricity generating equipment and also provides the hobbyists a few experimental projects in the form of homemade windmills and dynamo generators:

How the Stator in an Alternator Works

How to Check an Alternator Using an Oscilloscope

How to Troubleshoot a Car Alternator

What is the Purpose of an Alternator on Ships?

How Alternators are Protected in Ships

How do Free Piston Linear Alternators Work?

How Hydroelectric Generator Motors Work

How to Calculate Wind Turbines Efficiency

How to Enhance Windmill Efficiency

Understanding Aermotor Windmills

Generating Green Power from Home Windmill Generators

How to Protect an Alternator from Reverse and Low Voltages

How Onshore Wind Turbines Work

How to Make a Windmill from a Bicycle Dynamo

How to Make a Model Windmill Generator

How to Make a Homemade Windmill Generator