Control house layout – 3

Cableways

Cable routing can be accomplished by using any of several methods.

Cable Trenches

Cable trenches are formed into the concrete floor slab and are covered with metal plates. The covers should be flush with the finished floor when in place.

The sizes and locations of the cable trenches are based on the quantities of cables and locations of panels and equipment to be interconnected. Usually, a cable trench is located adjacent to the backs of the control and relay panels to facilitate panel interconnections.

With duplex panels, it may be desirable to use the entire space between the front and rear panels as cable trench, depending on circuit quantities.

Figure 12 – Concrete cable trenches in control house

Figure 12 – Concrete cable trenches in control house

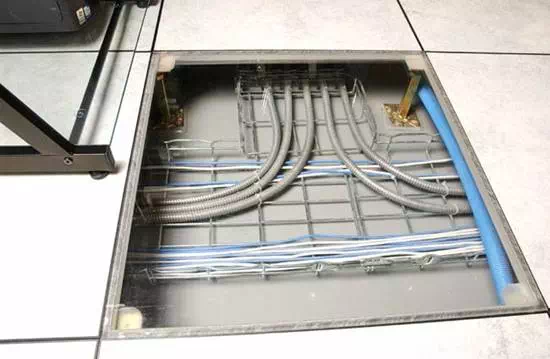

False Floors

False floors are useful when large open areas are desirable for cable routing. Lightweight removable floor panels installed on adjustable pedestals are positioned in areas requiring extensive cable interconnections or where future plans dictate a large amount of cable rerouting.

The top of the removable panels should be flush with the finished floor.

When cables are mounted under false floors, establish routes and paths in which cables should be routed. This will allow the separation of circuits as required to maintain system reliability based on duplicate circuits.

If circuits in one area are damaged, other undamaged circuits in the other parts of the building are likely to keep the substation in service.

Conduits

Conduits can be used for cable routing in floors, along walls, and for cable entrance into the control house. Conduits are available in plastic, aluminum, and steel. Each of these types may be used in control houses for wire containment to convenience outlets, lighting fixtures, and other control house auxiliary power equipment.

Plastic conduit is easily installed and is available in a variety of sizes. Take adequate physical and thermal precautions when using plastic conduit to ensure safe operation.

Metallic conduits of aluminum and steel are widely used as control house cableways. Intermediate- and heavy-walled steel conduit provide excellent physical protection.

Figure 13 – Cables in false floor of a substation control house

Figure 13 – Cables in false floor of a substation control house

The installed costs, however, may be relatively high because of the extensive labor required for installation. The installed cost of rigid aluminum conduit may be somewhat less than that for steel.

A lower installed cost may be realized by using thin-walled steel conduit (i.e., electrical metallic tubing) since it is less expensive and easier to install.

Wireways

Wireways are sheet-metal troughs used for routing groups of power circuits around a control house to feed various branch circuits. Conduit is used between the wireway and the devices.

Wireway offers the advantage of laying rather than pulling the cable into position and the ability to change or reroute circuits easily. Wireway is available with hinged or removable covers in a variety of lengths and sizes.

Select and install wireway in accordance with the National Electrical Code.

Figure 14 – Cables laid on metallic wireways in false floor

Figure 14 – Cables laid on metallic wireways in false floor

Cable Trays

Cable trays can be used for overhead routing of cables to and between control and relay panels. Expanded metal or ladder-type trays provide the best facilities for conductors entering and leaving the trays.

An advantage of cable trays is the ability to lay rather than pull in the conductors. Suspended cable trays, however, prevent extensive use of this technique because of support locations.

A large variety of types, sizes, and fittings is available to suit individual requirements. Cable tray should be selected and installed in accordance with the NEC and NEMA Standards.

Figure 15 – Cables in trays entering panels

Figure 15 – Cables in trays entering panels