Control house at HV/EHV switchyards and substations (construction, layout and functions)

Control house

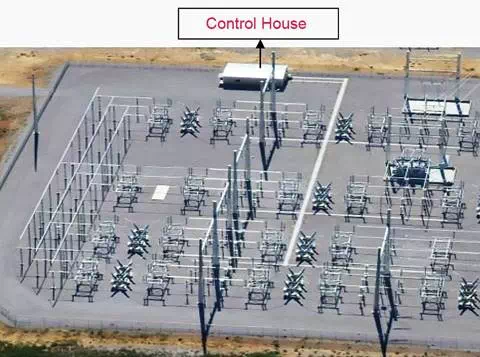

Nowadays, the control house is one of the main parts in every modern HV switchyard and substation. Why? Simply, because substations have grown in complexity and equipment such as circuit breakers, switch disconnectors, CT, VTs and others must be controlled, monitored and protected from some common point in the field.

Control house at HV/EHV switchyards and substations (construction,

layout and functions) - photo credit: eq-house.com

Control house at HV/EHV switchyards and substations (construction,

layout and functions) - photo credit: eq-house.com

Necessity for supplemental equipment such as protection relays, controls, batteries, communications equipment, and LV distribution equipment also increases. And all that equipment must be placed somewhere in the field.

That’s why substation needs a control house. In short.

For small distribution substations, this equipment can usually be contained in weatherproof enclosures or control cabinets. For larger substations, separate equipment housing is necessary.

A control house provides a weatherproof and, if required, environmentally controlled enclosure for supplemental substation equipment. Additional space can be provided for workshops, equipment testing and repair, storage areas, and lavatory facilities.

MV and LV switchgear can also be contained within control houses, or this equipment may be contained within weatherproof enclosures dedicated to that purpose.

Figure 1 – Location of control house in power substation

Figure 1 – Location of control house in power substation

Control house construction

This section discusses general aspects of the control house construction.

Foundation

The control house foundation typically consists of a spread footing with either masonry blocks or cast-inplace walls. The footing is designed for an allowable bearing capacity based on soil data. If soil data is not available, a maximum bearing of 48 kPa can be used.

The footings are installed below frost depth and in accordance with local building codes and practices.

Drilled piers are an alternative to spread footings. Drilled piers are especially applicable for pre-engineered metal buildingswith structural supporting bases that can rest directly on the piers without requiring a concrete floor slab. Soil data is necessary for determining the required depth, diameter, and reinforcing of the piers.

Damp-proofing of foundation walls is desirable, especially if concrete block is used. If a basement level is constructed, damp-proofing should be provided.

Footing drains are usually provided when a basement level is constructed. All foundation walls should be insulated with a 5.1-cm (2-inch) thickness of rigid insulation for energy conservation.

It is preferable to install the insulation on the inside of the walls, although the outside is acceptable.

Figure 2 – New control house piers poured and cables installed

before the control house arrives

Figure 2 – New control house piers poured and cables installed

before the control house arrives

Floor

The control house floor is typically a floating concrete slab 12 to 16 cm thick reinforced with welded wire fabric, deformed steel bars, or a combination of both.

The finished floor elevation is usually 10 to 20 cm above the finished grade outside the control house.

The base beneath the floor slab should be 10-12 cm of compacted sand or gravel, thoroughly mixed and compacted sand or gravel, or thoroughly mixed and compacted natural soil. A 0.15 mm thick plastic film vapor barrier should be installed between the floor slab and the base.

The method for cable routing in the control house has to be considered before finalization of the floor slab design. Cable trenches can be formed into the floor slab, or false floors can be installed providing access to large areas below the finished floor.

Control house structure

The control house structure must be constructed from fire-resistant, low-maintenance building materials. Most control houses presently being designed and constructed are of the pre-engineered metal or masonry block type.

Figure 3 show example of control building structure type.

The pre-engineered metal building is the easiest to procure and erect. The manufacturer can design and fabricate the required building components when given the building size; wind, snow, and ice loads; and any special requirements such as additional roof loads for suspended cable trays or other equipment.

Masonry buildings constructed of block masonry are most economical when masonry module dimensions are used to size the building and the building openings.

Figure 3 – Control house on the left

Figure 3 – Control house on the left

Two types of roof systems are commonly used for masonry buildings: pre-cast, pre-stressed concrete panels; and steel joists and steel decks. A sloping roof is recommended for both systems and can be obtained by pitching the roof deck or installing tapered roof insulation.

The roof membrane has to be compatible with the slope. For the slopes of 8.3 cm/m (1 in./ft) and less, built-up pitch and slab is commonly used. For greater slopes, gravel is used.

The control house should be equipped with at least one double door, possibly with a removable transom, conveniently located to facilitate equipment entry and removal. In certain circumstances a second exit needs to be installed in the control house.

The National Electrical Safety Code (NESC) states:

If the plan of the room or space and the character and arrangement of equipment are such that an accident would be likely to close or make inaccessible a single exit, a second exit shall be provided.

The National Electrical Code (NEC) also defines specific requirements for a second exit. The doors should include locking devices, astragals to prevent water from entering, and adequate weatherstripping and hardware to permit a rapid exit from the control house.

Adequately ventilate the battery area, either by a natural or powered ventilation system, to limit accumulation of hydrogen gas to less than an explosive mixture. A powered ventilation system needs to be annunciated to indicate ventilation failure. Provide portable or stationary water facilities or a neutralizing agent for rinsing eyes and skin in the battery area in addition to proper eye protection and clothing.

Locate and mark adequate fire-extinguishing equipment in the control house. Windows can be provided, if desired, in office and lavatory areas. Battery rooms and control and metering areas do not need windows.

Consider adequate methods for building insulation. These methods include use of insulated wall panels, ceiling insulation, storm doors, and windows, and weatherstripping around all openings.

Metal buildings are shop painted and require only minor field touch-up after erection. Masonry buildings may be left unpainted or may be painted with portland cement or latex paint. Tint all prime coats to match the finished coat.