Mechatronic Systems

A natural stage in the evolutionary process of modern engineering design is encompassed in the area known as mechatronics. The term mechatronics was coined in Japan in the 1970s . Mechatronics is the synergistic integration of mechanical, electrical, and computer systems and has evolved over the past 30 years, leading to a new breed of intelligent products. Feedback control is an integral aspect of

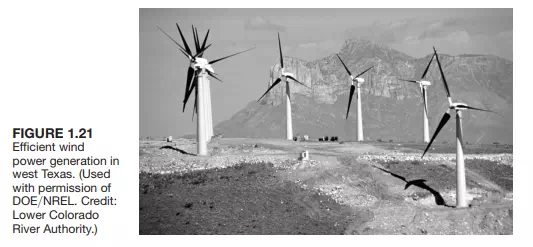

modern mechatronic systems. One can understand the extent that mechatronics reaches into various disciplines by considering the components that make up mechatronics [74–77]. The key elements of mechatronics are (1) physical systems modeling, (2) sensors and actuators, (3) signals and systems, (4) computers and logic systems, and (5) software and data acquisition. Feedback control encompasses aspects of all five key elements of mechatronics, but is associated primarily with the element of signals and systems, as illustrated in Figure 1.19.

Advances in computer hardware and software technology coupled with the desire to increase the performance-to-cost-ratio has revolutionized engineering design. New products are being developed at the intersection of traditional disciplines of engineering, computer science, and the natural sciences. Advancements in traditional disciplines are fueling the growth of mechatronics systems by providing “enabling technologies.” A critical enabling technology was the microprocessor which has had a profound effect on the design of consumer products. We should expect continued advancements in cost effective microprocessors and microcontrollers, novel sensors and actuators enabled by advancements in applications of microelectromechanical systems (MEMS), advanced control methodologies and realtime programming methods, networking and wireless technologies, and mature computer-aided engineering (CAE) technologies for advanced system modeling, virtual prototyping, and testing.The continued rapid development in these areas will only accelerate the pace of smart (that is, actively controlled) products.

An exciting area of future mechatronic system development in which control systems will play a significant role is the area of alternative energy production and usage. Hybrid fuel automobiles and efficient wind power generation are two examples of systems that can benefit from mechatronic design methods. In fact, the mechatronic design philosophy can be effectively illustrated with the example of the evolution of the modern automobile [70]. Prior to the 1960s, the radio was the only significant electronic device in an automobile. Today, many automobiles have 30–60 microcontrollers, up to 100 electric motors, about 200 pounds of wiring, a multitude of sensors, and thousands of lines of software code. A modern automobile can no longer be classified as a strictly mechanical machine—it has been transformed into a comprehensive mechatronic system.

EXAMPLE 1.1 Hybrid fuel

vehicles Recent research and development has led to the next generation hybrid fuel automobile, depicted in Figure 1.20. The hybrid fuel vehicle utilizes a conventional internal combustion engine in combination with a battery (or other energy storage device such as a fuel cell or flywheel) and an electric motor to achieve a propulsion system capable of doubling the fuel economy over conventional automobiles. Although these hybrid vehicles will never be zero-emission vehicles (since they have internal combustion engines), they can reduce the level of harmful emissions from one-third to one-half, and with improvements envisioned in the future, these emissions may reduce even further. As stated earlier, the modern automobile requires many advanced control systems to operate. The control systems must regulate the performance of the engine, including fuel–air mixtures, valve timing, transmissions, wheel traction control, antilock brakes, and electronically controlled suspensions, among many other responsibilities. On the hybrid fuel vehicle, there are additional control functions that must be satisfied. Especially necessary is the control of power between the internal combustion engine and the electric motor, determining power storage needs and implementing the battery charging, and preparing the vehicle for low-emission start-ups. The overall effectiveness of the hybrid fuel vehicle depends on the combination of power units that are selected (e.g., battery versus fuel cell for power storage). Ultimately, however, the control strategy that integrates the various electrical and mechanical components into a viable transportation system strongly influences the acceptability of the hybrid fuel vehicle concept in the marketplace.

he second example of a mechatronic system is the advanced wind power generation system.

EXAMPLE 1.2 Wind power

Many nations in the world today are faced with unstable energy supplies often leading to rising fuel prices and energy shortages. Additionally, the negative effects of fossil fuel utilization on the quality of our air are well-documented. The problem is that many nations have an imbalance in the supply and demand of energy. Basically, they use more than they produce. To address this imbalance, many engineers are considering developing advanced systems to access other sources of energy, including wind energy. In fact, wind energy is one of the fastest-growing forms of energy generation in the United States and in other locations around the world. A wind farm now in use in western Texas is illustrated in Figure 1.21. In 2002, the installed global wind energy capacity was over 31,000 MW. In the United States, there was enough energy derived from wind to power over 3 million homes (according to the American Wind Energy Association). For the past 30 years, researchers have concentrated on developing technologies that work well in high wind areas (defined to be areas with a wind speed of at least 6.7 m s at a height of 10 m). Most of the easily accessible high wind sites in the United States are now utilized, and improved technology must be developed to make lower wind areas more cost effective. New developments are required in materials and aerodynamics so that longer turbine rotors can operate efficiently in the lower winds, and in a related problem, the towers that support the turbine must be made taller without increasing the overall costs. In addition, advanced controls will have to be employed to enable the level of efficiency required in the wind generation drive train.

Advances in alternate energy products, such as the hybrid automobile and the generation of efficient wind power generators, provide vivid examples of mechatronics development. There are numerous other examples of intelligent systems poised to enter our everyday life, including smart home appliances (e.g., dishwashers, vacuum cleaners, and microwave ovens), wireless network enabled devices, “human-friendly machines” [81] which perform robot-assisted surgery, and implantable sensors and actuators.