Compressor Anti-Surge Control

The purpose of an anti-surge control is to keep the compressor from going into surge on reduced flow. Surge is an instability exhibited by a centrifugal as flow is reduced below the surge point. An anti-surge control is recommended for all centrifugal compressor applications.

Pipelines transporting gases and vapours are invariably dependent

on centrifugal or turbo-compressors for the propulsion of these fluids. Under

normal operation, with the compressor running at any constant speed there is a

specific relationship between the pressure head across the compressor and the

flow through it. But this stable relationship can be disturbed by sudden

changes in flow, pressure and density, usually caused by sudden variations in

demand downstream of the compressor or in the case of systems requiring

multiple compressors a disturbance can be caused by the switching of

compressors in and out of service. All these can give rise to formidable pulsations

of pressure and flow, better known as a surge. Surges may also develop at

start-up and whenever the compressor is required to operate during periods of

very low flow. Under these conditions, the compressor finds the flow too low

for conversion to the required discharge pressure.

The only way to prevent surging is to recycle or blow down a portion of the

flow to keep the compressor away from it's surge limit. Unfortunately,

compressing extra flow results in a severe economic penalty. Thus, the

control system must be able to accurately determine the compressor's operating

point as to provide adequate, but not excessive, recycle flow.

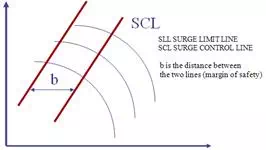

A Surge Limit Line (SLL) is the line connecting the various surge points of a compressor at varying RPMs. The set point of the anti-surge controller is represented on the compressor map shown in Figure by a line which runs parallel to the surge limit line. This line is called the Surge Controller Line (SCL). The controller is then able to calculate the deviation from the operating point to the SCL.

In practice, the load changes can happen very quickly so the anti-surge instrumentation and valves must have a fast response. Times to travel from the fully closed to the fully open position will vary with the valve’s rated travel but, typically, a valve with a travel of 510mm may be required to open in less than 2 seconds and one with a travel of 120mm should open in 0.75 seconds.

The compressor surge limit is not fixed with respect to any one measured variable such as compression ratio or pressure drop across the flow meter. Instead, it is a complex function that is dependent on the gas composition, RPM, suction temperature, and pressure. The valve must be large enough to prevent surging under all possible operating conditions. However, a valve which is too oversized will result in poor control.

The control valves specified for most process control applications are sized for maximum flow conditions but, for anti-surge compressor service, the sizing must address the conditions that may be conducive to surges at different flow requirements and different compressor speeds. Some of these factors are contradictory in sizing terms. One or more volume boosters are often required to ensure fast response and equal opening and closing time. Fail position should be open.