STANDARD & CALIBRATION

CALIBRATION

Calibration is the process of making an adjustment or marking a scale so that the readings of an instrument agree with the accepted & the certified standard.

In other words, it is the procedure for determining the correct values of measurand by comparison with the measured or standard ones.

The calibration offers a guarantee to the device or instrument that it is operating with required accuracy, under stipulated environmental conditions.

The calibration procedure involves the steps like visual inspection for various defects, installation according to the specifications, zero adjustment etc.,

The calibration is the procedure for determining the correct values of measurand by comparison with standard ones. The standard of device with which comparison is made is called a standard instrument. The instrument which is unknown & is to be calibrated is called test instrument. Thus in calibration, test instrument is compared with standard instrument.

Types of calibration methodologies:

There are two methodologies for obtaining the comparison between test instrument & standard instrument. These methodologies are

i) Direct comparisons

ii) Indirect comparisons

Direct comparisons:

In a direct comparison, a source or generator applies a known input to the meter under test. The ratio of what meter is indicating & the known generator values gives the meter¶ s error. In such case the meter is the test instrument while the generator is the standard instrument. The deviation of meter from the standard value is compared with the allowable performance limit.

With the help of direct comparison a generator or source also can be calibrated.

Indirect comparisons:

In the indirect comparison, the test instrument is compared with the response standard instrument of same type i .e., if test instrument is meter, standard instrument is also meter, if test instrument is generator; the standard instrument is also generator & so on.

If the test instrument is a meter then the same input is applied to the test meter as well a standard meter.

In case of generator calibration, the output of the generator tester as well as standard, or set to same nominal levels.

Then the transfer meter is used which measures the outputs of both standard and test generator.

Standard

All the instruments are calibrated at the time of manufacturer against measurement standards.

A standard of measurement is a physical representation of a unit of measurement.

A standard means known accurate measure of physical quantity.

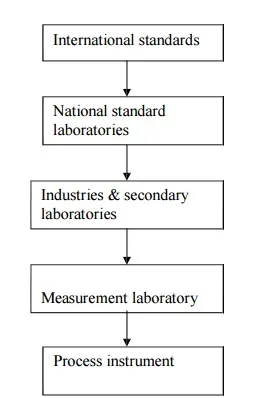

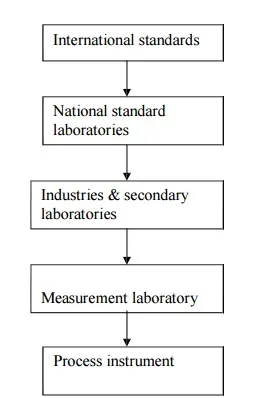

The different size of standards of measurement are classified as

i) International standards

ii) Primary standards

iii) Secondary standards

iv) Working standards

International standards

International standards are defined as the international agreement. These standards,as mentioned above are maintained at the international bureau of weights an d measures and are periodically evaluated and checked by absolute measurements in term s of fundamental units of physics.

These international standards are not available to the ordinary users for the calibration purpose.

For the improvements in the accuracy of absolute measurements the international units are replaced by the absolute units in 1948.

Absolute units are more accurate than the international units.

Primary standards

These are highly accurate absolute standards, w hich can be used as ultimate reference standards. These primary standards are maintained at national standard laboratories in different countries.

These standards representing fundamental units as well as some electrical and mechanical derived units are calibrated independently by absolute measurements at each of the national laboratories.

These are not available for use, outside the national laboratories.

The main function of the primary standards is the calibration and verification of secondary standards.

Secondary standards

As mentioned above, the primary standards are not ava ilable for use outside the national laboratories.

The various industries need some reference standards. So, to protect highly accurate primary standards the secondary standards are maintained, which are designed and constructed from the absolute standards. These are used by the measurement and calibration laboratories in industries and are maintained by the particular industry to which they belong. Each industry has its own standards.

Working standards

These are the basic tools of a measurement laboratory and are used to check an d calibrate the instruments used in laboratory for accuracy and the performance.