Transformer Ratio Bridges & Self-Balancing Bridges

TRNSFORMER RATIO BRIDGES

INTRODUCTION

The product to which this manual refers should be installed, commissioned, operated and maintained under the supervision of a competent Electrical Engineer in accordance with relevant statutory requirements and good engineering practice, including Codes of Practice where applicable, and properly used within the terms of the specification.

The instructions in this manual should familiarize qualified personal with the proper procedures to keep all new unit(s) in proper operating condition. These instructions for installation, operation and maintenance of Package Compact Substation should be read carefully and used as a guide during installation and initial operation.

These instructions do not propose to cover all details or variations in equipment, nor to provide for every contingency to be met in connection with installation, operation, or maintenance. Should further information be desired, or particular problems arise which are not covered, please contact the nearest ABB office.

We would in particular stress the importance of care in:

• Site selection and design, embodying features that provide adequate ventilation, protection and security and which have taken account of appropriate fire, moisture and explosion hazards.

• Jointing.

• Earthing.

• Selection and setting of electrical protection in primary and secondary, against overload, overvoltage and short-circuit.

• Carrying out regular inspection and electrical and mechanical maintenance.

The Package Compact Substation(s) covered by these instructions have been repeatedly inspected and tested to meet all applicable standards of IEC, to ensure you of a first-rate quality product, which should give many years of satisfactory performance.

The specific ratings of each Package Compact Substation are shown on the drawings.

File these instructions in a readily accessible place together with drawings and descriptive data of the Package Compact Substation. These instructions will be a guide to proper maintenance of the equipment and prolong its life and usefulness

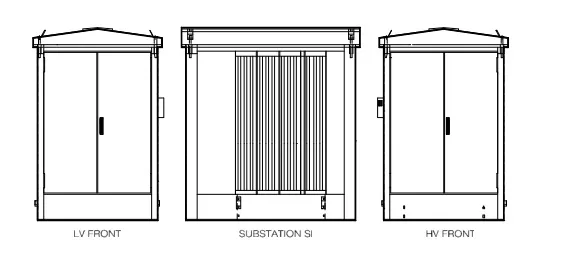

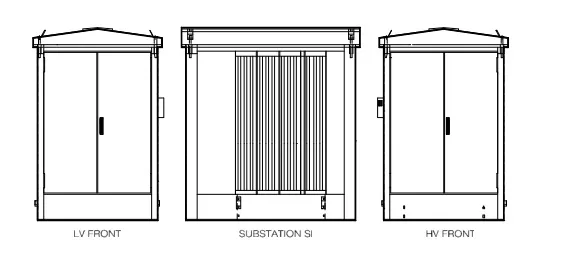

GENERAL

The Package Compact Substations are completely self-contained, mounted on an integral base, factory assembled in a totally enclosed, aesthetically and acceptable cladding, vandal-proof, vermin-proof and weather-proof housing ready for installation into position on a concrete base pad or pier. The base frame is of welded structural steel and been hot-dipped galvanized after fabrication to assure affective corrosion resistance in service. Housing of the Package Compact Substation is made of special material called ALUZINK, a sheet steel with a metallic alloy coating. The alloy consists of 55% aluminum and 43.4% zinc. This provides optimum corrosion protection. The housing has three compartments, separated with ALUZINK sheet. The transformer compartment is completely separated from the medium voltage and low voltage compartments.

RECEIVING / INSPECTION / STORAGE

The Package Compact Substation is shipped from the factory ready for installation on site. It has been submitted to all normal routine tests before being shipped, and it is not required to do any voltage testing before putting it into service, provided the substation has not sustained any damage during transportation.

Immediately upon receipt of the Package Compact Substation, examine them to determine if any damage or loss was sustained during transit. If abuse or rough handling is evident, file a damage claim with carrier and promptly notify the nearest ABB office. ABB ELECTRICAL INDUSTRIES CO. LTD. is not responsible for damage of goods after delivery to the carrier; however, we will lend assistance if notified of claims.

PERSONNEL SAFETY

The first and most important requirements are the protection against contact with live parts during normal service as well as maintenance or modifications.

This is the reason why all live parts have been metal enclosed, so that when the parts are live and the Package Compact Substation doors are open, no one can be able to touch them.

Also, it is safe in case any short-circuiting or sparking occurs at the busbars.

VENTILATION

Transformer compartment has been provided with sand trap louvers, to prevent ingress of sand and that proper air circulation should take place.

EARTHING

Proper earthing busbar has been provided.

HANDLING

Lifting lugs has been provided on top of four corners of the housing for lifting the DPS by crane and chains as a single unit, otherwise this can be done by a forklift of sufficient capacity, but the lifting fork must be positioned under the transformer portion.

INSTALLATIONS

A clean, flat surface capable of supporting the Package Compact Substation unit weight is the only requirement for a foundation. It is, however, important that adequate accessibility, ventilation and ease of inspection of the unit must be provided.

In all installation work, the safety regulations for electrical installations have to be observed.

Each Package Compact Substation must be permanently grounded or earthed by connecting an affective recognised ground or earth as prescribed by the latest applicable edition of IEC or ANSI requirements. The Package Compact Substation is designed to operate with a solidly grounded neutral system. The neutral connection should be solidly and permanently grounded.

Tap connections

All units have taps located in the High Voltage winding. The tap arrangement is shown on the nameplate of the transformer. These taps are provided to furnish rated output voltage when the input voltage differs from the rated voltage.

To change tap connections, do the following steps:

1. De-energized the unit, short-circuit both the high and low voltage connections and ground both sides.

2. Unlock the tap changer handle, and then move the taps changer handle to the desired tap, then locked the tap changer handle.

3. Remove safety shorts and ground connections from the high voltage and low voltage buses.

After ensuring that no tools or hardware was left in the enclosure, and the enclosures are closed properly, you may then re-energize the Package Compact Substation. Make sure that the tap connections are proper for the required voltage as listed on the nameplate. The transformer is normally shipped with the tap changer for the rated voltage.

Cable connections

When making outside cable connections, conductors suitable for at least 85°C should be used. All connections should be made without placing undue stress on the terminals. Conductors should be securely fastened in place and adequately supported with allowances for expansion and contraction.

FINAL INSPECTION PRIOR TO ENERGIZATION

After the Package Compact Substation has been found to be in good condition and the protective equipment is operational, the substation may be connected to the network. However, it is recommended that the transformer to be left to settle for 1 or 2 days after installation so those air bubbles in the oil have time to dissolve before connecting the voltage.

Before energizing the unit, a complete electrical inspection should be made. The following checklist should be used as a minimum requirement.

Electrical Inspection

All external connections have been made properly (phasing of connections to terminals, etc.).

All connections are tight and secure.

All accessory circuits are operational. Check the transformer protective equipment and test the function of their electrical circuits: Thermometers (alarms, tripping)

Pressure relay (tripping)

Oil level indicator

Ensure that all fuses are inserted and in the correct position

All tap connections are properly positioned.

The neutral and ground connections have been properly made.

Mechanical Inspection

All shipping members have been removed.

There is no obstructions in or near the openings for ventilation.

No tools or other articles are left inside the enclosures.

All protective covers are in place or closed and bolted tight.

MAINTENANCE AND PERIODIC INSPECTION

In order to assure a long lifetime and correct and reliable operation of equipment delivered for this facility it is of utmost importance to perform maintenance regularly.

Following general rules should always be considered before starting maintenance activity.

1. Authority from responsible engineer shall always be obtained before starting any maintenance.

2. Follow safety procedure established in carrying out the work.

Realize that no set of safety or maintenance instructions will ever be written that can adequately cover all accident possibilities.

Therefore "SAFETY" as dictated by actual current conditions, always takes precedence over any previously prepared safety or maintenance instructions. Assume nothing. Take the precautions that you personally deem necessary in addition to those included in standard practice.

• Be familiar with the drawings and previous test records before starting activity.

• Scrutinize maintenance instructions given for the equipment to be maintained. Maintenance information is given in the Operation and Maintenance Manual for each type of equipment.

The main dangers of such process are:

• Inaccessible lubrication points (greased for life) cannot be lubricated and may seize up.

• Areas not lubricated may be subject to corrosion.

• The high-pressure spray may damage equipment.

• Especially protective coatings may be removed.

Bolt Tightness

All connections should be tight and secure. Bolts and nuts on busbar and terminal lugs should be torqued and marked properly.

Inspection and Testing

The need for preventive maintenance will vary on operating conditions. Where heavy dust conditions exist, an accumulation of dust on the equipment may effect the operation of unit substation and its protective apparatus.

When normal maintenance inspection and cleaning of bus connections, relays, lug connections, and other part of the distribution system is being made, it is advisable to operate and check circuit breakeror switch-disconnector operation.

Routine Field Testing

Routine field testing of the electrical equipment is intended to enable maintenance personal to determine, without laboratory conditions or complicated equipment, that a particular electrical equipment is able to perform its basic circuit functions.

The following constitutes a guide to tests that might be performed during routine maintenance.

1. Insulation Resistance Test

Extreme atmospheres and conditions may reduce the dielectric withstandability of any insulating material. An instrument commonly known as "megger" is used to perform this test.

The voltage recommended for this test should be at least 50 percent greater than the circuit rating; however, a minimum of 500 volts is permissible. Tests should be made between phases of opposite polarity as well as from current carrying parts of the circuit protective device to ground. Also, a test should be made between the line-and-load terminals with the circuit protective device in the "OFF" position.

Resistance values below one megaohm are considered unsafe and should be investigated for possible contamination on the surfaces.

NOTE: For individual circuit protective device's resistance readings, load and line conductors should be disconnected. If not disconnected, the test measurements will also include the characteristics of the attached circuits.

A temperature and humidity reading are recommended and recorded during the testing period.

Insulation resistivity is markedly effected by temperature and humidity conditions. Based condition of one (1) megaohm per kV assumes a 20°C wet bulb reading. The following table shall be used to adjust readings to the 20°C constant.

2. Connection Test

Connections to the circuit protective device should be inspected to determine that a proper electrical joint is present. If overheating in these connections is evident by discoloration or signs of arcing, the connections should be removed and the connecting surfaces clean before re-connections. It is essential that electrical connections be made properly to prevent and reduce overheating.

3. Mechanical Operation

During routine tests, mechanical operation of the circuit protective devices or disconnects should be checked by turning it "ON" and "OFF" at least three times.