Thermal,

hydel & nuclear power stations

In this section we briefly outline the basics of the three

most widely found generating stations – thermal, hydel and nuclear plants in

our country and elsewhere.

Thermal plant

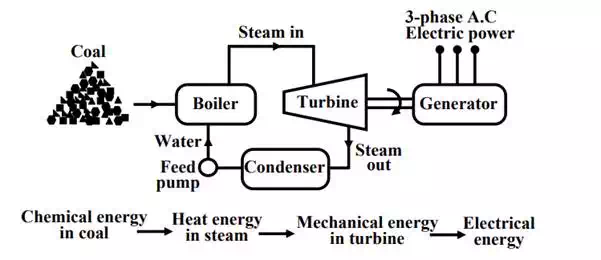

We have seen in the previous section that to generate voltage at 50 Hz we have to run the generator at some fixed rpm by some external agency. A turbine is used to rotate the generator. Turbine may be of two types, namely steam turbine and water turbine. In a thermal power station coal is burnt to produce steam which in turn, drives the steam turbine hence the generator (turbo set). In figure the elementary features of a thermal power plant is shown.

In a thermal power plant coil is burnt to produce high temperature and high pressure steam in a boiler. The steam is passed through a steam turbine to produce rotational motion. The generator, mechanically coupled to the turbine, thus rotates producing electricity. Chemical energy stored in coal after a couple of transformations produces electrical energy at the generator terminals as depicted in the figure. Thus proximity of a generating station nearer to a coal reserve and water sources will be most economical as the cost of transporting coal gets reduced. In our country coal is available in abundance and naturally thermal power plants are most popular. However, these plants pollute the atmosphere because of burning of coals.

Basic components of a thermal generating unit

Stringent conditions (such as use of more chimney heights along with the compulsory use of electrostatic precipitator) are put by regulatory authorities to see that the effects of pollution is minimized. A large amount of ash is produced every day in a thermal plant and effective handling of the ash adds to the running cost of the plant. Nonetheless 57% of the generation in our country is from thermal plants. The speed of alternator used in thermal plants is 3000 rpm which means 2-pole alternators are used in such plants.

Hydel plants

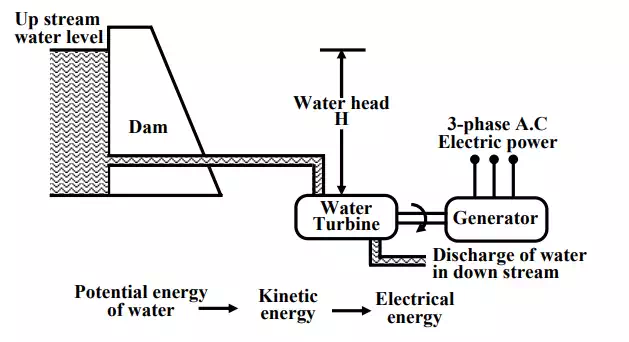

In a hydel power station, water head is used to drive water turbine coupled to the generator. Water head may be available in hilly region naturally in the form of water reservoir (lakes etc.) at the hill tops. The potential energy of water can be used to drive the turbo generator set installed at the base of the hills through piping called pen stock. Water head may also be created artificially by constructing dams on a suitable river. In contrast to a thermal plant, hydel power plants are eco-friendly, neat and clean as no fuel is to be burnt to produce electricity. While running cost of such plants are low, the initial installation cost is rather high compared to a thermal plants due to massive civil construction necessary. Also sites to be selected for such plants depend upon natural availability of water reservoirs at hill tops or availability of suitable rivers for constructing dams. Water turbines generally operate at low rpm, so number of poles of the alternator are high. For example a 20-pole alternator the rpm of the turbine is only 300 rpm.

Basic components of a hydel generating unit.

Nuclear plants

As coal reserve is not unlimited, there is natural threat to thermal power plants based on coal. It is estimated that within next 30 to 40 years, coal reserve will exhaust if it is consumed at the present rate. Nuclear power plants are thought to be the solution for bulk power generation. At present the installed capacity of nuclear power plant is about 4300 MW and expected to expand further in our country. The present day atomic power plants work on the principle of nuclear fission of 235U. In the natural uranium, 235U constitutes only 0.72% and remaining parts is constituted by 99.27% of 238U and only about 0.05% of 234U. The concentration of 235U may be increased to 90% by gas diffusion process to obtain enriched 235U. When 235U is bombarded by neutrons a lot of heat energy along with additional neutrons are produced. These new neutrons further bombard 235U producing more heat and more neutrons. Thus a chain reaction sets up. However this reaction is allowed to take place in a controlled manner inside a closed chamber called nuclear reactor. To ensure sustainable chain reaction, moderator and control rods are used. Moderators such as heavy water (deuterium) or very pure carbon 12C are used to reduce the speed of neutrons. To control the number neutrons, control rods made of cadmium or boron steel are inserted inside the reactor. The control rods can absorb neutrons. If we want to decrease the number neutrons, the control rods are lowered down further and vice versa. The heat generated inside the reactor is taken out of the chamber with the help of a coolant such as liquid sodium or some gaseous fluids. The coolant gives up the heat to water in heat exchanger to convert it to steam as shown in figure 2.4. The steam then drives the turbo set and the exhaust steam from the turbine is cooled and fed back to the heat exchanger with the help of water feed pump. Calculation shows that to produce 1000 MW of electrical power in coal based thermal plant, about 6 × 10^6 Kg of coal is to be burnt daily while for the same amount of power, only about 2.5 Kg of 235U is to be used per day in a nuclear power stations.

Nuclear power generation.

The initial investment required to install a nuclear power station is quite high but running cost is low. Although, nuclear plants produce electricity without causing air pollution, it remains a dormant source of radiation hazards due to leakage in the reactor. Also the used fuel rods are to be carefully handled and disposed of as they still remain radioactive.

The reserve of 235U is also limited and cannot last longer if its consumption continues at the present rate. Naturally search for alternative fissionable material continues. For example, plutonium (239Pu) and (233U) are fissionable. Although they are not directly available. Absorbing neutrons, 238U gets converted to fissionable plutonium 239Pu in the atomic reactor described above. The used fuel rods can be further processed to extract 239Pu from it indirectly increasing the availability of fissionable fuel. Effort is also on to convert thorium into fissionable 233U. Incidentally, India has very large reserve of thorium in the world.

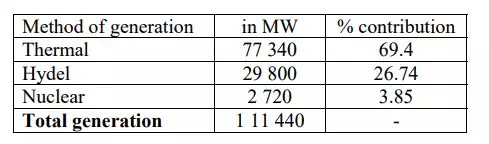

Total approximate generation capacity and Contribution by thermal, hydel and nuclear generation in our country are given below.

Non-conventional sources of energy

The bulk generation of power by thermal, hydel and nuclear plants are called conventional methods for producing electricity. Search for newer avenues for harnessing eco-friendly electrical power has already begun to meet the future challenges of meeting growing power demand. Compared to conventional methods, the capacity in terms of MW of each nonconventional plant is rather low, but most of them are eco-friendly and self-sustainable. Wind power, solar power, MHD generation, fuel cell and power from tidal waves are some of the promising alternative sources of energy for the future.