Generation, Transmission and Distribution of Electric Power

Basic idea of generation Prior to the discovery of Faraday’s Laws of electromagnetic discussion, electrical power was available from batteries with limited voltage and current levels. Although complicated in construction, D.C generators were developed first to generate power in bulk. However, due to limitation of the D.C machine to generate voltage beyond few hundred volts, it was not economical to transmit large amount of power over a long distance. For a given amount of power, the current magnitude (I = P/V), hence section of the copper conductor will be large. Thus generation, transmission and distribution of d.c power were restricted to area of few kilometre radius with no interconnections between generating plants. Therefore, area specific generating stations along with its distribution networks had to be used.

Changeover from D.C to A.C

In later half of eighties, in nineteenth century, it was proposed to have a power system with 3- phase, 50 Hz A.C generation, transmission and distribution networks. Once a.c system was adopted, transmission of large power (MW) at higher transmission voltage become a reality by using transformers. Level of voltage could be changed virtually to any other desired level with transformers – which was hitherto impossible with D.C system. Nicola Tesla suggested that constructionally simpler electrical motors (induction motors, without the complexity of commutator segments of D.C motors) operating from 3-phase a.c supply could be manufactured. In fact, his arguments in favour of A.C supply system own the debate on switching over from D.C to A.C system.

A.C generator

A.C power can be generated as a single phase or as a balanced poly-phase system. However, it was found that 3-phase power generation at 50 Hz will be economical and most suitable. Present day three phase generators used to generate 3-phase power are called alternators (synchronous generators). An alternator has a balanced three phase winding on the stator and called the armature. The three coils are so placed in space that there axes are mutually 120° apart as shown in figure. From the terminals of the armature, 3-phase power is obtained. Rotor houses a field coil and excited by D.C. The field coil produces flux and electromagnetic poles on the rotor surface. If the rotor is driven by an external agency, the flux linkages with three stator coils becomes sinusoidal function of time and sinusoidal voltage is induced in them. However, the induced voltages in the three coils (or phases) will differ in phase by 120° because the present value of flux linkage with R-phase coil will take place after 120° with Y-phase coil and further 120° after, with B-phase coil. A salient pole alternator has projected poles as shown in figure(a). It has non-uniform air gap and is generally used where speed is low. On the other hand a non-salient pole alternator has uniform air gap (figure(b)) and used when speed is high.

3 -phase generators.

Frequency, voltage & interconnected system

The frequency of the generated emf for a p polar generator is given by

![]()

here n is speed of the generator in rps or

![]() when

n is in rpm. Frequency of the generated voltage is standardized to 50 HZ in our

country and several European countries. In USA and Canada it is 60 Hz. The

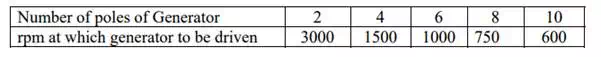

following table gives the rpm at which the generators with different number of

poles are to be driven in order to generate 50 Hz voltage.

when

n is in rpm. Frequency of the generated voltage is standardized to 50 HZ in our

country and several European countries. In USA and Canada it is 60 Hz. The

following table gives the rpm at which the generators with different number of

poles are to be driven in order to generate 50 Hz voltage.

A modern power station has more than one generator and these generators are connected in parallel. Also there exist a large number of power stations spread over a region or a country. A regional power grid is created by interconnecting these stations through transmission lines. In other words, all the generators of different power stations, in a grid are in effect connected in parallel. One of the advantages of interconnection is obvious; suppose due to technical problem the generation of a plant becomes nil or less then, a portion of the demand of power in that area still can be made from the other power stations connected to the grid. One can thus avoid complete shutdown of power in an area in case of technical problem in a particular station. It can be shown that in an interconnected system, with more number of generators connected in parallel, the system voltage and frequency tend to fixed values irrespective of degree of loading present in the system. This is another welcome advantage of inter connected system. Inter connected system however, is to be controlled and monitored carefully as they may give rise to instability leading to collapse of the system.

All electrical appliances (fans, refrigerator, TV etc.) to be connected to A.C supply are therefore designed for a supply frequency of 50 Hz. Frequency is one of the parameters which decides the quality of the supply. It is the responsibility of electric supply company to see that frequency is maintained close to 50 Hz at the consumer premises.

It was pointed out earlier that a maximum of few hundreds of volts (say about 600 to 700 V) could be developed in a D.C generator, the limitation is imposed primarily due to presence of commutator segments. In absence of commutators, present day generated voltage in alternator is much higher, typically around 10 kV to 15 kV. It can be shown that rms voltage induced in a coil is proportional to φ and n i.e., Ecoil ∝ φ n where φ is the flux per pole and n is speed of the alternator. This can be justified by intuition as well: we know that mere rotating a coil in absence of magnetic flux (φ) is not going to induce any voltage. Also presence of flux without any rotation will fail to induce any voltage as you require rate of change of flux linkage in a coil. To control the induced voltage one has to control the d.c field current as speed of the alternator gets fixed by frequency constrain.