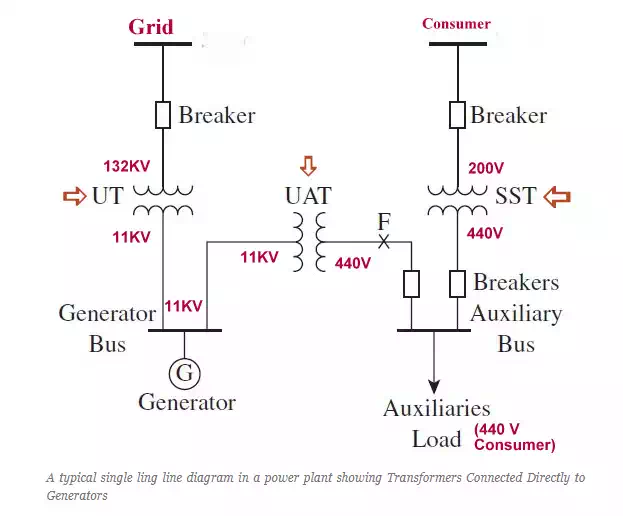

Discussion on Transformers Connected Directly to Generators

C57.116-1989 is the IEEE Guide for Transformers Directly Connected to Generators. This guide describes selection and application considerations for transformer connected to generators.

The consideration is for unit transformer & unit auxiliary transformers; and also for if connections directly or via circuit breaker, load break switch etc.

Types of power transformer used with generators

Three types of power transformers associated connected with

generators-

1. Unit transformers (UT), directly connects the system (high voltage consumer, grid etc.) and the generator. When these types of transformer transform the generator voltage step up to transmission voltage then called as Generator step-up (GSU) transformers.

2. Unit auxiliary transformers (UAT), directly connects the auxiliary system to the generator.

3. Station service transformers (SST), is not directly connected to the generator. It connects the auxiliary bus to the system.

If you consider a common situation- an 11KV generator generates power to the grid, then unit transformer step up 11KV to 132KV transmission voltage. Now to drive the generator there is some associated auxiliary system running like boiler, electric pump, compressor, even the consumerís basics (fan, ac, lighting etc.). This auxiliary system is 400-440 voltage. A unit auxiliary transformer is used to step down 11KV to 440 volt and provide power to the auxiliary system. A station service transformer is used to interconnect a system and the auxiliary bus system. This might be used to further step down or may be for isolation.

Generator step-up (GSU) transformers: GSU units transform the voltage up from the generator voltage level to the transmission voltage level.

Auxiliary loads of Generator: The auxiliary system which are required for to run the generator such as boiler to produce continuous steam, compressor to maintain air pressure, fuel pump to provide fuel, cooling fan in the radiator and in the generator etc.

Special design consideration for Transformers Connected Directly to Generators

∑ Lowering the core flux density at rated voltage to allow for operation at higher V/Hz without saturation of the core

∑ Increasing the design margin on the mechanical-withstand capability of the windings to account for the possibility of a fault occurring during a period of over excitation.

∑ Increased Thermal capacity of the transformer to prevent overheating due to increased currents.