How to do maintenance of contacts in Magnetic Contactor.

Contacts in magnetic contactor are the part which suffer stress, heat due to mechanical movement, electrodynamic effect and arcs. Thus maintenance of contacts is a very important job and need to be done by skilled hand.

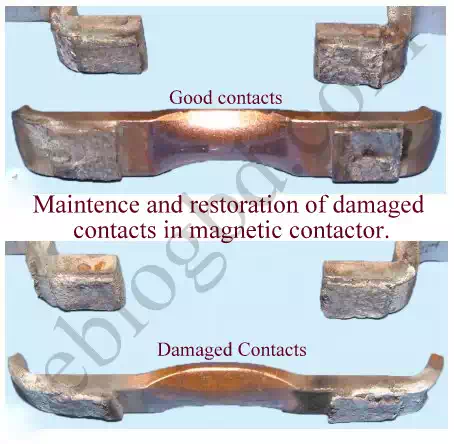

How to select a damaged or worn out contact in magnetic contactor

It is the hard part to choose which contact is good or bad. If the surface of the contact is rough & discoloured, that does not mean that it is damaged and need to be replaced. In fact changing a contact in magnetic contactor for less important reason is prohibited as the contact in used is already ”electrically seated” and make good contact over a larger surface.

If any contact is to be replaced, all the three contact must be replaced by a same set of contacts plus the arc chutes also must be changed.

Maintenance of contacts in magnetic contactor

Maintenance or restoration of contacts in magnetic contactor must be done carefully. As the restoration process may add some other difficulties. General restoration procedures are filling, grinding, scraping etc. If this restoration process is done, the contact resistance might be increased due to scrap from this grinding and filing.

What is AC hum & Contact bounce in Magnetic Contactor.

AC hum and bounce of contact in magnetic contactor is due to mechanically damaged contact and variation of terminal voltage.

AC Hum in magnetic Contactor

Pollution of the magnet pole surfaces will create a slight hum coming from the contactor in the closed position. Hum can also occur if the pole surfaces are deformed. A louder hum will occur if the shading coil is broken because the magnet will cause the contactor to chatter.

If so the complete contactor needs to be exchanged. Another reason for AC-hum could be corrosion caused by environmental conditions that exceed the contactor specifications. Contactors need to be protected from condensation in order to keep the pole surfaces of the magnet free from corrosion.

Contact bounce in magnetic contactor:

The operational limit of the contactor is between 85 and 110% of the rated coil voltage according to IEC60947-4-1. A voltage variation of ±5% of the above limits will increase the contact bounce that leads to increased contact wear . The reason for this is that higher voltages will increase the speed of the electromagnet at closing.

Lower voltages will decrease the speed at closing. Both these factors can lead to a higher level of contact bounce at closing. High voltage and the increased speed at closing also contribute to some increased sound.