Speed simulation of diesel engine- details.

The speed simulation of diesel engine is the checking the functionality of over speed trip system. That is say for a diesel engine, the normal running speed is 750RPM and shut down speed is set 840RPM. When the engine reach at 840RPM, the safety system must shut down the engine. Our speed simulation purpose is to check the integrity of this shut down system.

One thing must be clear, by speed simulation we are not checking the sensors and not even the trip circuit. We are only checking the engine shut down device or process. Under over speed if the alarm is raised or not, the shutdown command initiates or not , the over speed(if any) device functions or not etc.

Say in Wartsila 20V32 engine, there are pneumatic shutdown device to stop the engine. In this case we will check the integrity of this system and other system associated with it

The concept of speed simulation of Diesel engine

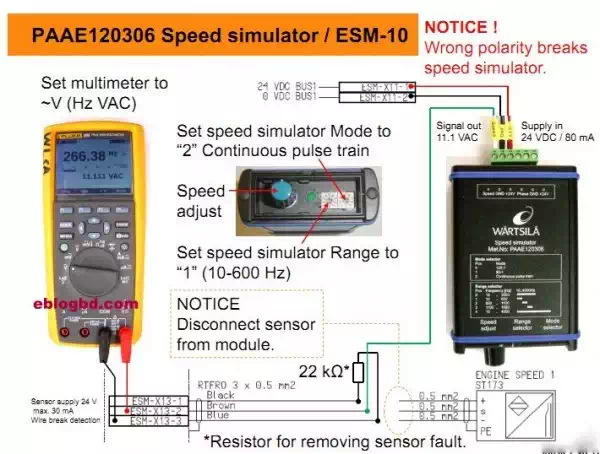

As we know the Speed sensor output to engine is varying frequency. We will just provide the certain matched frequency with the shutdown speed. Say in this case the shutdown RPM is 840, and the related frequency is 266Hz. We will inject this frequency to speed sensor slot in control cabinet and slow increase the frequency to 266KHz. If the trip signal activates then the shutdown system is fine otherwise there is problem or fault in the system.

Process of speed simulation:

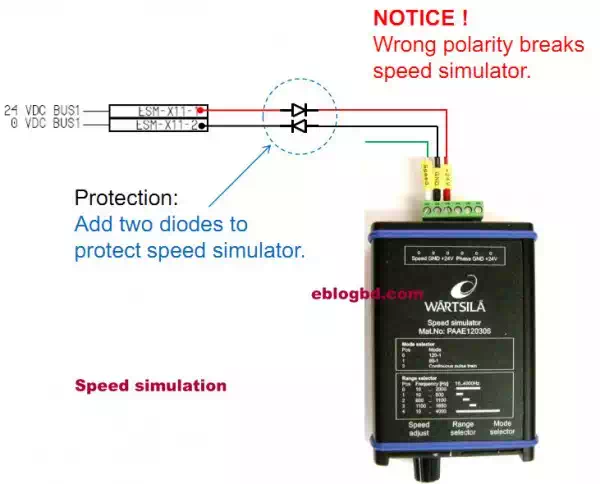

The first thing is to disconnect the speed sensor wire from control cabinet. A certain wire from sensor is led in to control board and connected to it in a certain slot. We need to disconnect it. In this very slot we will place the speed simulation designated wire (certainly as per instruction from the manufacturer).

Things to sort out before

Speed sensor fault blocking of engine. As you have disconnected the speed sensor, there might be sensor fault alarm and blocking of engine. This an enhanced safety system of engine that it will not run unprotected with the speed sensor out of order or connection broken whatever.

To avoid this a 22KOhm resistor can be attached in the slot of speed sensor wire or instructions as per manufacturer recommendation.

The next thing is lube oil sensor output. Its another enhanced safety for engine running. We know what would happen if the engine run without enough lube oil. The mechanical breakdown is likely to happen without lube oil. To speed simulate the engine a certain 4-20 mili amps signal must be injected to the slot of lube oil sensor output in control cabinet, then the safety system will find that there is enough lube oil pressure to run the engine.

Say if if required lube oil pressure is 3bar , then the injected ampere should be 12 mili amp. [You can find this in Details on P/I converter- pressure to current converter.]

So everything is set as per the manufacturer recommendation and the concept we gain here. The next is to inject the required frequency to the marked slot in the control cabinet.

Speed

simulation total process. With Wartsila ESM engine safety module

Speed

simulation total process. With Wartsila ESM engine safety module