Insulation resistance test of alternator – how to do safely.

The insulation resistance test of alternator is very important. The IR test must be done in regular interval of minimum 6 month. Plus any time IR test may be needed to do if there are symptom of burning of stator.

Insulation resistance test method of alternator

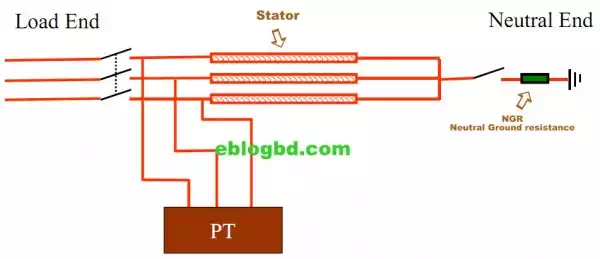

There is no difference of insulation test that of other equipment and that of alternator. But as the complete isolation of a subject wire is the main concept of insulation resistance, caution and perfect knowledge of alternator connection need to be known before proceeding.

So the main concept is to complete isolation of test subject. Synchronous alternator are mostly of star connected. First thing to disconnect the star connection and also disconnect the protective device or measurement device like CT, PT. Then we can continue to Insulation resistance of Alternator.

Internal

connection of Alternator

Internal

connection of Alternator

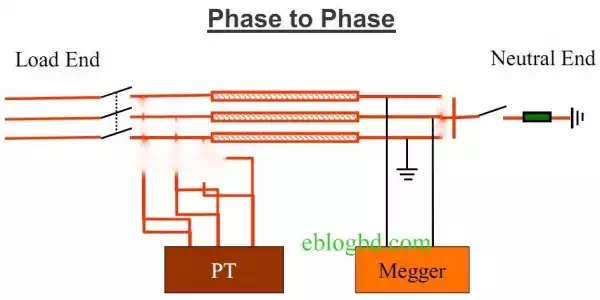

Phase

to Phase insulation resistance test

Phase

to Phase insulation resistance test

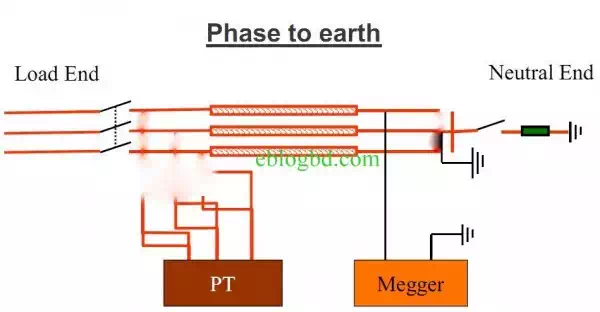

Phase to earth insulation resistance test connection

Phase to earth insulation resistance test connection

What is insulation resistance & how it is calculated.

Insulation resistance or IR test is a very important maintenance procedure to check out the integrity or health of an electrical system. If the insulation resistance is found high, we can say an equipment or system is fine otherwise it’s not.

Now there is insulation resistance measurement tools called megger to find the insulation resistance of any equipment. We can handle the tools but what about the working principle of this tools or how the IR is calculated.

What is Insulation resistance

The first thing is that when doing Insulation resistance test we are applying direct current (DC) not alternating current(AC).

So we are applying a permissible level of DC voltage on any equipment and thus there will be current flow. As we are checking the insulation test for an equipment to earth, there is no physical connection to them. Thus there will current between them which will be in micro amps.

Now as R=(V/I), this simple

equation led is to get the insulation resistance. R=insulation resistance.

But remember that the total value of measured insulation resistance= small

internal resistance of equipment insulation resistance.

If the insulation strength is high, value of R will be low and if the insulation is weak the IR will be low with high current.

Factors that affect the Insulation resistance

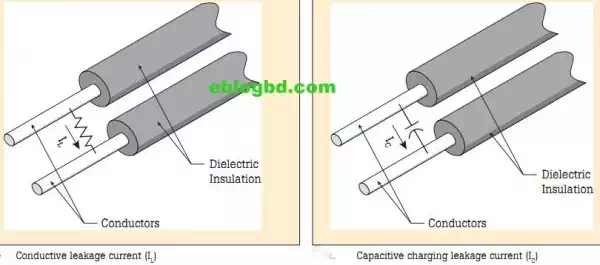

Conductive leakage current (IL)

Conductive current is a small (micro-amp) amount of current that normally flows through insulation, between conductors or from a conductor to ground.

This current increases as insulation deteriorates and becomes predominant after the absorption current vanishes. Because it is fairly steady and time independent, this is the most important current for measuring insulation resistance.

Capacitive charging leakage current (IC )

When two or more conductors are run together in a raceway, they act as a capacitor. Due to this capacitive effect, a leakage current flows through conductor insulation.

This current lasts only for a few seconds as the dc voltage is applied and drops out after the insulation has been charged to its full test voltage.

In low-capacitance equipment, the capacitive current is higher than conductive leakage current, but usually disappears by the time we start recording the data. Because of this, it is important to let the reading “settle out” before recording it.

On the other hand, when testing high capacitance equipment the capacitive charging leakage current can last for a very long time before settling out.

Polarization absorption leakage current (IA )

Absorption current is caused by the polarization of molecules within dielectric material. In low-capacitance equipment, the current is high for the first few seconds and decreases slowly to nearly zero. When dealing with high capacitance equipment or wet and contaminated insulation, there will be no decrease in the absorption current for a long time.