What is rotor balancing weight or key in alternator and its function.

Rotor balancing weight is provided to reduce the excessive vibration due to its high speed rotation. Excessive vibration has some severe impact on the prime mover and alternator.

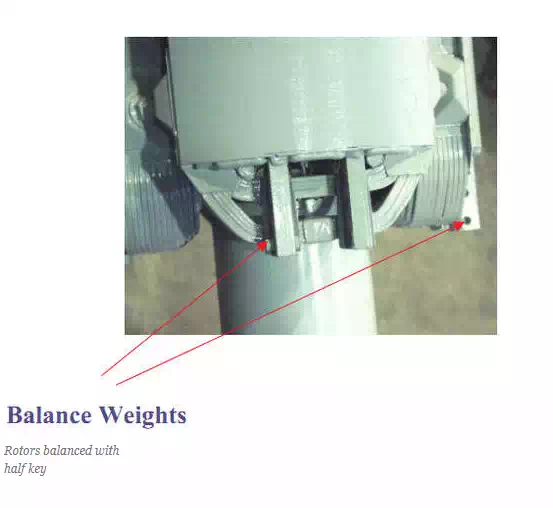

What is rotor balancing weight

Rotor balancing weight or key in alternator is a counter balance weight to minimize the vibration due to rotating rotor.

Why rotor balancing weight needed.

With proper alignment of the prime mover and alternator there is possibility of minimum vibration but some time the vibration is beyond limit- then the balancing weight is applied to reduce the vibration.

If the machine is driven by a belt, the use of balancing weight is mandatory.

The rotor in alternator is rotating at immense speed with its heavy structure and weight. The speed is slow for diesel engines coupled alternator from 100 rpm to 3000rpm but with gas turbine coupled alternator this speed might be more than 50000 rpm.

With the high rotating speed naturally there is vibration occurs but this is kept to within some limit. Excessive vibration causes severe mechanical damage like breakdown of rotor shaft, gears and even the engine structure. This is basically due to the coupling of alternator and the prime mover.

A single body without coupling is not endangered with vibration but with a coupling the scenario is different. Caution is taken to ensure the vibration and misalignment of alternator and prime mover.

There is some vibration sensor is attached to sense the vibration and if its exceeds beyond the limit there is direct shut down signal initiated.