Alternator alignment with prime mover – how to do & test.

Alternator alignment with the prime mover is very important. With a little misalignment there will be severe vibration that will cause mechanical breakdown of structure.

The alignment is needed for both to machines with either flexible or rigid couplings.

Alignment procedure for machines

The alignment procedure is different for machines from different manufacturer. It is recommended to follow strictly the alignment procedure provided by the machine manufacturer. As even slight errors of alignment result in damaged bearings.

Always follow the manufacture

data and documentation.

For perfect coupling allow for thermal expansion at the electrical machine and

the drive.

Machines with a steel disc coupling

On machines with a steel disc coupling, radial rotor alignment is by means of centering screws inserted into the centering bell. These screws also act as transit keepers in a radial direction. They replace the press board inserts otherwise placed in the air gap. Alignment is checked by measuring the distance between the outer rim of the steel disc coupling and the machined inner diameter of the centering bell.

Machines with an undivided bearing plate

If the machine has an undivided bearing plate, a machined end disc is installed at the drive side.

The measurement is then made between the shaft and the machined inner diameter of the end plate.

Take three measurements in each case, at 120 degree intervals round the shaft. The results must not vary by more than 0,2 mm. This will ensure a uniform air gap beneath all poles and the correct axial position of the rotor. Check alignment accuracy at the end of the shaft or at the coupling.

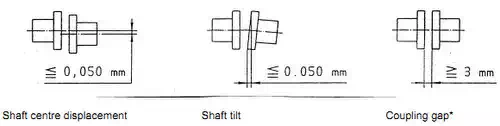

Checking of alternator alignment with prime mover

While checking, turn the coupling slowly through 360°C, at the same time taking the readings at the individual dial gauges. Attach one dial gauge radially and two axially, to compensate for rotor displacement. Refer to the coupling manufacturer’s data as a guide

to permissible deviations from true alignment.