Why transformer oil is used in transformer & its types.

The core-coil of transformer carry high voltage and current. The surrounding construction is isolated from the core-coil. A certain distance is maintained from the core-coil which is called “Electrical Clearance”. Plus the surrounding medium is maintained electrical isolated (dielectric) that charge cannot pass through the medium.

With air as surrounding dielectric medium the electrical clearance must be high. Thus a transformer become large and bulky. Plus with heavy stresses like in fault condition air might lose its dielectric property becoming ionized or electrically conductive.

On the other-hand both the dielectric and cooling property of liquid mineral or transformer oil is much higher than the air. Thus for compact design transformer oil is a better choice for transformer dielectric medium.

What is dielectric

A dielectric material (or in short dielectric) is an electrical insulator that can be polarized by an applied electric field. When a dielectric is placed in an electric field, electric charges do not flow through the material.

Why transformer oil is used in transformer

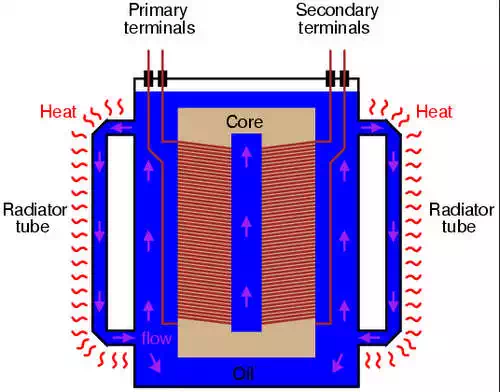

Mineral oil surrounding a transformer core-coil assembly are called “Transformer oil” enhances the dielectric strength of the winding and prevents oxidation of the core. Dielectric improvement occurs because oil has a greater electrical withstand than air and because the dielectric constant of oil is closer to that of the insulation.

As a result, the stress on the insulation is lessened when oil replaces air in a dielectric system. Oil also picks up heat while it is in contact with the conductors and carries the heat out to the tank surface by self-convection.

Thus a transformer immersed in oil can have smaller electrical clearances and smaller conductors for the same voltage and kVA ratings.

Core-coil

of transformer is immersed in Oil

Core-coil

of transformer is immersed in Oil

Transformer oil types

Below are the coolant being used now-a-days.

01. High-Temperature Hydrocarbons

High-temperature hydrocarbons (HTHC), also called high-molecular-weight hydrocarbons. These coolants are classified by the National Electric Code as “less flammable” if they have a fire point above 300˚C. The disadvantages of HTHCs include increased cost and a diminished cooling capacity from the higher viscosity that accompanies the higher molecular weight.

02. Esters

Synthetic esters are being used in Europe, where high-temperature capability and biodegradability are most important and their high cost can be justified, for example, in traction (railroad) transformers.

Transformer manufacturers in the U.S. are now investigating the use of natural esters obtained from vegetable seed oils.