Why iron core is thin & laminated in transformer instead of solid core.

Iron core is thin & laminated in transformer to avoid the loss of eddy current. Eddy current is induced in core and circulates normal to the width of the core causing heat.

Why iron core is thin & laminated in transformer

The iron core transformer has higher permeability thus it is applied in transformer in place of air core in modern transformer. But a solid iron core has some own disadvantage due to to some losses. Thus to reduce the losses solid core is not used in transformer. Thin & laminated iron core is stacked up to form the complete core. This individual core are electrically separated from each other as this thin coating layer is an insulating material but let passes the magnetic flux.

When flux flows in the steel core, losses occur in the steel. There are two components of this loss, which are termed “eddy” and “hysteresis” losses.

If a solid core were used

in a power transformer, the losses would be very high and the temperature

would be excessive. For this reason, cores are laminated from very thin sheets,

such as 0.23 mm and 0.28 mm, to reduce the thickness of the individual sheets

of steel normal to the flux and thereby reducing the losses. Each sheet is

coated with a very thin material to prevent shorts between the lamination.

Hysteresis, Eddy current losses in transformer-

The hysteresis loss is caused by the cyclic reversal of flux in the magnetic circuit and can be reduced by metallurgical control of the steel. That is by choosing the material of steel.

Eddy loss is caused by eddy currents circulating within the steel induced by the flow of magnetic flux normal to the width of the core, and it can be controlled by reducing the thickness of the steel lamination or by applying a thin insulating coating.

Why iron core is used in transformer in place air core.

The ability of iron or steel to carry magnetic flux is much greater than air. This ability to carry flux is called permeability. Thus iron core is used in transformer in place air core.

Modern electrical steels have permeabilities in the order of 1500 compared with 1.0 for air. This means that the ability of a steel core to carry magnetic flux is 1500 times that of air.

Steel cores were used in power transformers when alternating current circuits for distribution of electrical energy were first introduced.

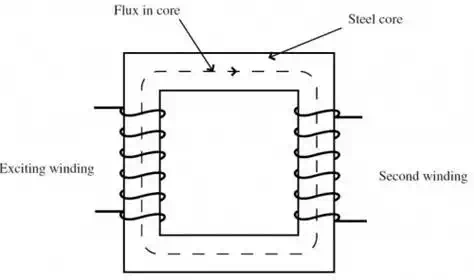

When two coils are applied on a steel core like below image almost 100% of the flux from coil 1 circulates in the iron core so that the voltage induced into coil 2 is equal to the coil 1 voltage if the number of turns in the two coils are equal.

Iron core transformer

Some small transformers for low-power applications are constructed with air between the two coils. Such transformers are inefficient because the percentage of the flux from the first coil that links the second coil is small.

What is positive and negative pressure.

In simple word a room will be in positive pressure if the air pressure in the room is higher than that of the surroundings air pressure. So no air will enter in to the room. If any leakage exist, air will egress (flow outward).

Positive pressure is used where outer air is not required in the room. Like in operation theatre of hospital surroundings air might carry air-borne germs. Or in some production areas where outer air might deviate the quality of product like in pharmaceutical industries.

What is Negative pressure

In simple word a room will be in negative pressure if the air pressure in the room is lower than that of the surroundings air pressure. So no air flow from the room under negative pressure. If any leakage exist, air will ingress (flow inward).

Negative pressure has some special use like in Generator room,

boiler room, transformer room. The harmful vapor or odor is kept inside the

room and control exhaust system is done safely.