Block Diagram of an Electrical Drives

Drive:

A combination of prime mover, transmission equipment and mechanical Working load is called a drive

An Electric Drive can be defined as an electromechanical device for converting electrical energy to mechanical energy to impart motion to different machines and mechanisms for various kinds of process control.

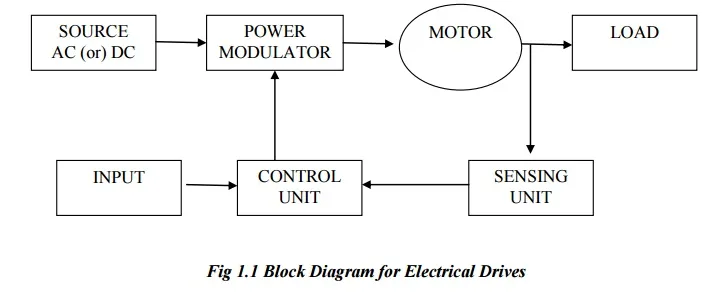

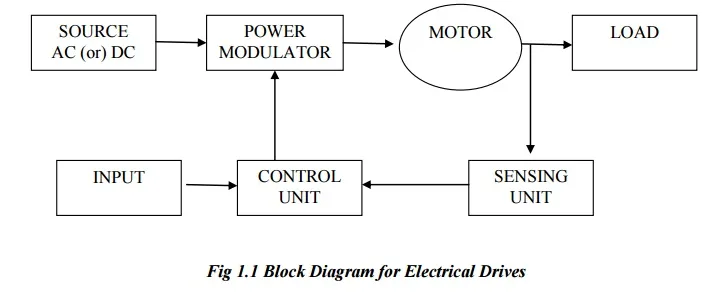

The basic block diagram for electrical drives used for the motion control is shown in the following figure1.1

The aggregate of the electric motor, the energy transmitting shaft and the control equipment by which the motor characteristics are adjusted and their operating conditions with respect to mechanical load varied to suit practical requirements is called as electric drive.

Drive system=Drive + load

1. BASIC COMPONENT (or) ELEMENTS OF ELETCRIC DRIVES

Block diagram of electric drive:

· Load: usually a machinery to accomplish a given task. Eg-fans, pumps, washing machine etc.

· Power modulator: modulators (adjust or converter) power flow from the source to the motion

· Motor: actual energy converting machine (electrical to mechanical)

· Source: energy requirement for the operation the system.

· Control: adjust motor and load characteristics for the optimal mode.

Power modulators:

Power modulators regulate the power flow from source to the motor to enable the motor to develop the torque speed characteristics required by the load.

The common function of the power modulator is,

· They contain and control the source and motor currents with in permissible limits during the transient operations such as starting, braking, speed reversal etc.

· They converts the input electrical energy into the form as required by the motors.

· Adjusts the mode of operation of the motor that is motoring, braking are regenerative.

Power modulators may be classified as,

· Converters uses power devices to convert uncontrolled valued to controllable output.

· Switching circuits switch mode of operation

· Variable impedance

They provide adjustable voltage/current/frequency to control speed, torque output power of the motor.

The various type of converters are,

o AC to DC rectifiers

o DC to DC choppers

o AC to AC chopper

o AC to AC –AC voltage controllers (voltage level is controlled)

o Cyclo converter (Frequency is controlled)

o DC to AC inverters

Switching circuits are needed to achieve any one of the following.

o Changing motor connection to change its quadrant of operation.

o Changing motor circuits parameters in discrete steps for automatic starting and braking control.

o For operating motors and drives according to a predetermine sequence

o To provide inter locking their by preventing maloperation

Disconnect under up normal condition Eg: electromagnetic contacters,

PLC in sequencing and inter locking operation, solid state relays etc.

Variable impedance

o Variable resisters are commonly used for AC and DC drives and also needed for dynamic braking of drives

o Semiconductors switch in parallel with a fixed resistance is used where stepless variation is needed. inductors employed to limit starting current of ac motors.