Tap Changing in Transformer

Tap Changing

Regulating the voltage of a transformer is a requirement that often arises in a power application or power system. In an application it may be needed

1. To supply a desired voltage to the load.

2. To counter the voltage drops due to loads.

3. To counter the input supply voltage changes on load.

On a power system the transformers are additionally required to perform the task of regulation of active and reactive power flows.

The voltage control is performed by changing the turns ratio. This is done by provision of taps in the winding. The volts per turn available in large transformers is quite high and hence a change of even one turn on the LV side represents a large percentage change in the voltage. Also the LV currents are normally too large to take out the tapping from the windings. LV winding being the inner winding in a core type transformer adds to the difficulty of taking out of the taps. Hence irrespective of the end use for which tapping is put to, taps are provided on the HV winding. Provision of taps to control voltage is called tap changing. In the case of power systems, voltage levels are sometimes changed by injecting a suitable voltage in series with the line.

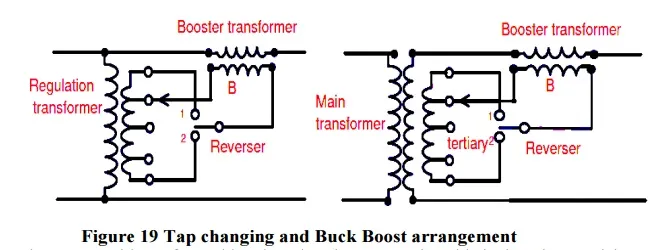

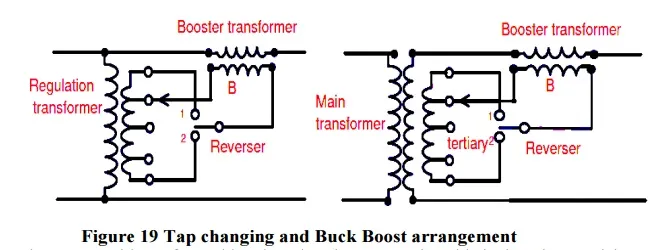

This may be called buck-boost arrangement. In addition to the magnitude, phase of the injected voltage may be varied in power systems. The tap changing arrangement and buck boost arrangement with phase shift are shown in Fig. 42. Tap changing can be effected when a) the transformers is on no- load and b) the load is still remains connected to the transformer. These are called off load tap changing and on load tap changing. The Off load taps changing relatively costs less. The tap positions are changed when the transformer is taken out of the circuit and reconnected. The on-load tap changer on the other hand tries to change the taps without the interruption of the load current.

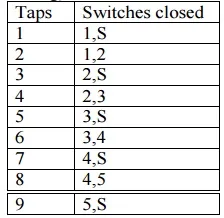

In view of this requirement it normally costs more. A few schemes of on-load tap changing are now discussed. Reactor method The diagram of connections is shown in Fig. 43. This method employs an auxiliary reactor to assist tap changing. The switches for the taps and that across the reactor(S) are connected as shown. The reactor has a center tapped winding on a magnetic core. The two ends of the reactor are connected to the two bus bars to which tapping switches of odd/even numbered taps are connected. When only one tap is connected to the reactor the shorting switch S is closed minimizing the drop in the reactor. The reactor can also be worked with both ends connected to two successive taps. In that case the switch ’S’ must be kept open. The reactor limits the circulating current between the taps in such a situation. Thus a four step tapped winding can be used for getting seven step voltage on the secondary(see the table of switching).

Reactor method the diagram of connections is shown in Fig. 43. This method employs an auxiliary reactor to assist tap changing. The switches for the taps and that across the reactor(S) are connected as shown. The reactor has a center tapped winding on a magnetic core. The two ends of the reactor are connected to the two bus bars to which tapping switches of odd/even numbered taps are connected. When only one tap is connected to the reactor the shorting switch S is closed minimizing the drop in the reactor. The reactor can also be worked with both ends connected to two successive taps. In that case the switch ’S’ must be kept open. The reactor limits the circulating current between the taps in such a situation. Thus a four step tapped winding can be used for getting seven step voltage on the secondary (see the table of switching). The advantage of this type of tap changer is

1. Load need not be switched.

2. More steps than taps are obtained.

3. Switches need not interrupt load current as a alternate path is always provided.

The major objection to this scheme seems to be that the reactor is in the circuit always generating extra loss. Parallel winding, transformer method In order to maintain the continuity of supply the primary winding is split into two parallel circuits each circuit having the taps. as

Two circuit breakers A and B are used in the two circuits. Initially tap 1a and 1b are closed and the transformer is energized with full primary voltage. To change the tap the circuit breaker A is opened momentarily and tap is moved from 1a to 2a. Then circuit breaker A is closed. When the circuit A is opened whole of the primary current of the transformer flows through the circuit B. A small difference in the number of turns between the two circuit exists. This produces a circulating current between them. Next, circuit breaker B is opened momentarily, the tap is changed from 1b to 2b and the breaker is closed. In this position the two circuits are similar and there is no circulating current. The circulating current is controlled by careful selection of the leakage reactance.

Generally, parallel circuits are needed in primary and secondary to carry the large current in a big transformer. Provision of taps switches and circuit breakers are to be additionally provided to achieve tap changing in these machines. Series booster method in this case a separate transformer is used to buck/boost the voltage of the main transformer. The main transformer need not be having a tapped arrangement. This arrangement can be added to an existing system also. It shows the booster arrangement for a single phase supply. The reverser switch reverses the polarity of the injected voltage and hence a boost is converted into a buck and vice versa. The power rating of this transformer need be a small fraction of the main transformer as it is required to handle only the power associated with the injected voltage.

The advantage of this type of tap changer are The major objection to this scheme seems to be that the reactor is in the circuit always generating extra loss. Parallel winding, transformer method In order to maintain the continuity of supply the primary winding is split into two parallel circuits each circuit having the taps. Two circuit breakers A and B are used in the two circuits. Initially tap 1a and 1b are closed and the transformer is energized with full primary voltage. To change the tap the circuit breaker A is opened momentarily and tap is moved from 1a to 2a. Then circuit breaker A is closed. When the circuit A is opened whole of the primary current of the transformer flows through the circuit B. A small difference in the number of turns between the two circuits exists. This produces a circulating current between them. Next, circuit breaker B is opened momentarily, the tap is changed from1b to 2b and the breaker is closed. In this position the two circuits are similar and there is no circulating current. The circulating current is controlled by careful selection of the leakage reactance. Generally, parallel circuits are needed in primary and secondary to carry the large current in a big transformer. Provision of taps switches and circuit breakers are to be additionally provided to achieve tap changing in these machines. Series booster method in this case a separate transformer is used to buck/boost the voltage of the main transformer. The main transformer need not be having a tapped arrangement.

This arrangement can be added to an existing system also. It shows the booster arrangement for a single phase supply. The reverser switch reverses the polarity of the injected voltage and hence a boost is converted into a buck and vice versa. The power rating of this transformer need be a small fraction of the main transformer as it is required to handle only the power associated with the injected voltage. One precaution to be taken with this arrangement is that the winding must output side. In smaller ratings this is highly cost effective. Two winding arrangements are also possible. The two winding arrangement provides electrical isolation. Not be open circuited. If it gets open circuited the core (B in fig) gets highly saturated.

In spite of the small ratings and low voltages and flexibility, this method of voltage control costs more mainly due to the additional floor space it needs. The methods of voltage regulation discussed so far basically use the principle of tap changing and hence the voltage change takes place in steps. Applications like a.c. and D.C. motor speed control, illumination control by dimmers, electro-chemistry and voltage stabilizers need continuous control of voltage. This can be obtained with the help of moving coil voltage regulators. Moving coil voltage regulator shows the physical arrangement of one such transformer. a, b are the two primary windings wound on a long core, wound in the opposite sense. Thus the flux produced by each winding takes a path through the air to link the winding. These fluxes link their secondaries a2 and b2. A short circuited moving coil s is wound on the same limb and is capable of being held at any desired position. This moving coil alters the inductances of the two primaries. The sharing of the total applied voltage thus becomes different and also the induced emf in the secondaries a2 and b2.

The total secondary voltage in the present case varies from 10 percent to 20 percent of the input in a continuous manner. The turn’s ratios of a1: a2 and b1: b2 are 4.86 and 10.6 respectively. 5 4.86 + 95 10.6 = 10% when s is in the top position. In the bottom position it becomes 95 4.86 + 5 10.6 = 20%. By selecting proper ratios for the secondaries a2 and b2 one can get the desired voltage variation. Sliding contact regulators these have two winding or auto transformer like construction. The winding from which the output is taken is bared and a sliding contact taps the voltage. The minimum step size of voltage change obtainable is the voltage across a single turn. The conductor is chosen on the basis of the maximum load current on the output side. In smaller ratings this is highly cost effective. Two winding arrangements are also possible. The two winding arrangement provides electrical isolation also.