Electrostatic Voltmeters

rek’s electrostatic voltmeters accurately measure surface potential (voltage) on materials. The company's non-contacting and contacting designs leverage Trek technologies. Trek also offers numerous probe options and on-board controllers.

Probe Information

A probe selection table provides technical and dimensional information for Trek’s probes that are utilized with the company’s electrostatic voltmeter models.

On Board Controller

TREK, INC., famous for its Electrostatic Voltmeters, is a world

class manufacturer of custom on-board controllers (OBCs) for electrostatic

voltmeter (ESVM) applications. These non-contacting on-board electrometers,

commonly referred to as on-board controllers (OBC), have an operating mean time

until failure rating of greater than 16,000 hours. These OBCs have been

installed in the products of leading electrophotographic copier and printer

manufacturers around the world. The Trek OBC employs a patented technique

to perform the non-contacting measurement of the electrostatic voltage level of

the photoconductor surface associated with electrophotographic processes.

The non-contacting technique allows high stability voltage measurement to be

made while the photoconductor surface is moving. High measurement accuracy is

maintained even if the OBC measurement probe to photoconductor surface distance

varies due to mechanical run-outs. The non-contacting method also insures that

no charge transfer to the probe occurs which would cause disruption of the

surface voltage. These OBCs can also be used in ESD applications to identify

sources of charge generation.

THE TREK PROBE

The Trek measurement probe used with its OBC is of the low

impedance type to provide a high signal-to-noise ratio thus achieving fast

speed of response together with superior noise and drift performance over wide

temperature and humidity ranges. The probe design is immune to the effects of

toner or other contaminants which often degrade the performance of probes in

other designs. The OBC features a precision voltage divider to provide a

low voltage buffered replica of the measured electrostatic photoconductor

surface voltage for output monitoring and control purposes.

TREK, INC. continues to innovate with new designs to meet the changing needs of

the electrophotographic industry for more accurate, higher speed, higher

quality, and lower cost OBC products. We would like to talk with you about your

particular needs and determine how these products or other Trek products can

meet your specific requirements. Please contact TREK, INC. for further

information about these product and their various applications.

on-Contacting Electrostatic Voltmeters

Information

about Electrostatic Voltmeter Technology and Electrostatic

Voltmeter Applications is

provided below the table.

Trek also offers

additional non-contacting voltmeters for ESD measurement.

Electrostatic Voltmeter Technology

Many very high impedance (> 1010 Ω) voltage measurements cannot be made using conventional type voltmeters because charge transfer into the voltmeter is required, thus causing loading and modification of the source voltage. For example, when measuring voltage distribution on a dielectric surface, any measurement technique that requires charge transfer, no matter how small, will modify or destroy the actual data. In these types of applications an electrostatic voltmeter is required. An instrument that measures voltage with virtually zero charge transfer is called an electrostatic voltmeter. A primary characteristic of electrostatic voltmeters is that they accurately measure surface potential (voltage) on devices or surfaces, with or without physical contact.

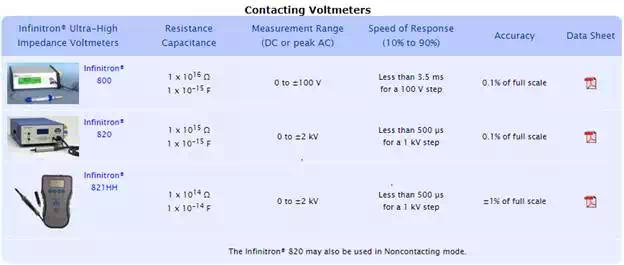

Trek is known for its novel non-contacting voltmeter designs, first introduced in 1968, to address charge transfer issues associated with the contacting voltmeter designs at the time. With these non-contacting electrostatic voltmeters an electrostatic voltage monitoring probe is placed in close proximity (1 mm to 5 mm) to the surface to be measured. These electrostatic voltmeters function to drive the potential of the probe body to the same potential as the measured unknown. This achieves a high accuracy non-contacting measurement that is insensitive to variations in probe-to-surface distances and prevents arc-over between the probe and measured surface. Trek’s more recently developed novel Infinitron® ultra-high impedance voltmeter technology is ideal for voltage measurement applications that demand virtually infinite loading impedance levels, far beyond the reach of currently available high impedance voltmeter instruments. The Infinitron technology enables contacting (and non-contacting) measurements to be made with virtually no charge transfer due to incredibly high input resistance of 1016 Ω combined with incredibly low input capacitance of 10-15 farads. This allows Trek’s Infinitron products to indicate, with high precision, the voltage level of objects and surfaces – even before contact is made.