Determining Applicable Standards

After each component in the plan has been selected, the step is to design each part to industry-recognized standards, as well as any additional standards set forth by the local jurisdiction for commercial or industrial occupancies. The primary industrial standard is the National Electric Code (NEC), published by the National Fire Protection Association (NFPA). The NEC is revised every three years and results in the publication of a new edition. It is good practice to make sure that your product is up-to-date with the recent edition revisions. Although the code is applied at a national level, some local jurisdictions may have additional standards that exceed the requirements of the the NEC or they may be use a previous edition of the code.

Some projects will also have additional requirements based on their specific components, such as those including specialized electrical equipment. An electrical designer should always consider manufacturer guidelines for specialized equipment and use the appropriate electrical equipment standards set forth by the manufacturer for overcurrent protection sizes, specialized grounding requirements, and so forth. These specialized requirements may need that additional specialized wiring practices be observed; when this is the case, these specialized requirements must be documented on the plan.

Designers must also consider the standards of the National Electrical Manufacturers Association (NEMA), which includes standards for motor lead identification, transformer terminal markings. plug and receptacle devices, and amperage ratings. Designers must also consider the standards for the Electrical Apparatus and Service Association (EASA), which provides current and updated information for motors and controls.

For projects that include new or upgraded parts

for distribution systems served from local utility, electrical designers must

consider any requirements set forth by the utility company. These methods may

dictate the wiring methods and equipment required for proper distribution form

the serving utility to the customer. Calculated load values must reference

manufacturer guidelines to ensure that distribution systems will support these

loads.

In all cases, designers must not only have solid electrical knowledge and a

thorough understanding of the electrical calculations and their necessity, but

also awareness of the application of all relevant code and standards utilized

within the electrical industry.

Creating the Electrical Plan

Once the various parts and applicable standards have been determined, the designer begins, compiling those parts to form the electrical design and complete a set of plans.

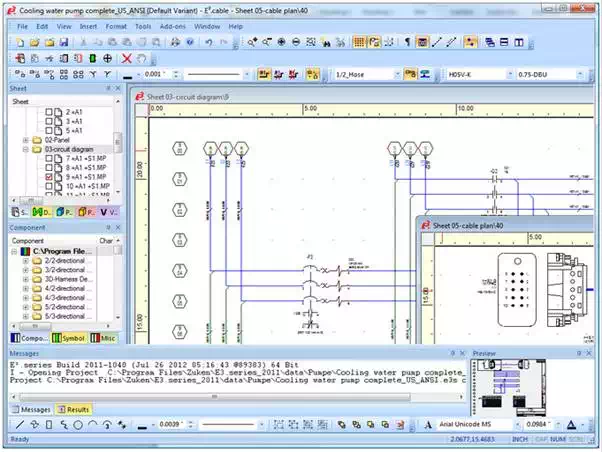

In the past these plans took the form of hand-drawn blueprints, but today most plans are created digitally using computer-aided design (CAD)software tools. Digitized plans are easier to revise and transmit than those drawn with pen and pencil.

On the plans, each device should be referenced using the appropriate electrical symbols. Electrical symbols allow for universal recognition of each part by the many persons who will be working on the project so that they can estimate cost appropriately and construct the project to the specifications.

Making sure that the correct symbols are utilized and written on the final design is vital. The design symbol list should be updated with the correct symbols and their definition. Occasionally the need may arise for a symbol that has not been developed (such as a newer energy-saving or energy management device). In this case, the designer may create a new symbol for the electrical design plan, as long as it is added to the symbols list included in the plan.

System Voltages

Understanding of various system voltages used in electrical systems is of great importance in their design and maintenance. Knowing how the loads are connected between phases and between phase and neutral will enable the electrical designer to properly design and specify the components of an electrical system and enable maintenance personnel to safely maintain and operate these systems.

There are many types of voltages for power supply, and knowing which one is available is step one. The voltage supply must be known from the utility company supplying it, not all servicing voltages are available for any load. For example, three-phase service may not be available for residential buildings, minimum load requirements may be specified for larger loads, and so on. The electrical designer is responsible for determining the service voltage requirements. Do not assume you know what power source you will be using, and design a device for one type of power source when its location won’t output such power.