Developing Competitive Automation Equipment

Industrial automation is making existing manufacturing companies more competitive. Many companies are realizing that there is great benefit for manufacturing facilities and partners that are closer to home. Foreign pricing, higher transportation costs, and lack of intellectual property rights in outsourced countries is shifting corporate thought in manufacturing outside their own country. Industrial automation is making that a very real possibility. But, with industrial automationís competition growing the need for better quality automation equipment is on the rise.

The need to produce quality automation products is even more obvious with the industry expanding and more and more competitors joining the race. To set your company apart from other emerging companies demands for more modern solutions that can help aid in product development and make a smooth transition between the mechanical and electrical engineering perspectives involved with all industrial automation equipment.

Electrical Schematic Design

Developing a proper schematic that is easily incorporated into the mechanical features of the automation equipment is essential to keep things aesthetically pleasing and functional. Documenting and designing electrical controls, servos, and wiring diagrams is important to keep everything in order and readily available for production. Last thing you want is errors occurring within the finished product that is not able to handle the power load or terminals that are not properly registered on the schematic diagrams.

Making sure that schematic design are tailored for electrical engineers to accurately build real-time rule checks with preventative programming to ensure that no errors ever occur. Last thing you want to do is run through pages and pages of wiring diagrams trying to find errors that is causing a malfunction. Improving design time will build a solid foundation for making the in-house electrical design process more competitive.

Making life easier for your electrical engineers will show in the long-run that better software or equipment will improve accuracy and production, just like the industrial automation that you are trying to supply to your very own consumers. Making the design process less stressful is the best way to improve response time, productivity, and lost time recovering from mistakes/errors.

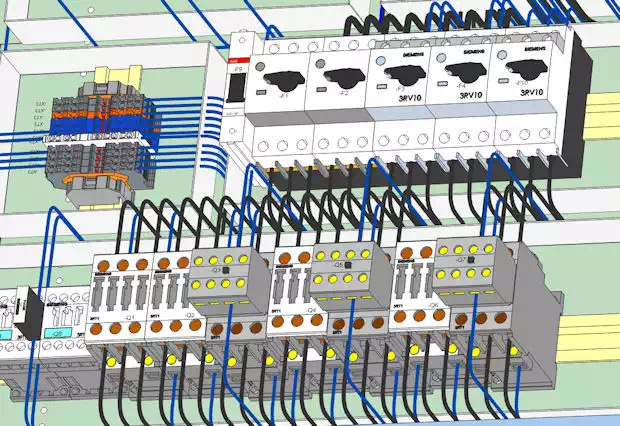

Circuit Panel Layout/Design

Being able to virtually represent your work is the best means of seeing the interconnections between all components involved in the product. Most companies have this capability, but the problem comes in when you need to represent physical space between two separate department designs. This is usually because many CAD programs on the market are dedicated to either electrical or mechanical CAD. Show the relationship between the component developed for the circuit panel and the housing developed for multiple components can be difficult to virtually represent.

Allowing engineers to display panel layout in relation to other mechanical components can have its weight in gold. What happens when component designs are finalized and after manufacturing the components have interference with one another. This means that deadline pressure and productivity would halt until the matter was resolved. Meaning that time is wasted on finding a solution for the issue, rather than completing it.

Using E3 To Make It Sophisticated and Simple

E3.series provides a comprehensive solution for design and documentation for complex electrical and electronic solutions. It has a massive multi-component library, unique circuit diagram representations, producing accurate, error-free documentation with simultaneous manufacturing and support.

This software offers features that can make industrial automation engineering easier with less hassle. It provides support features for schematic design, with E3.schematic, to provide an easy user interface for electrical engineers. This includes easy-to-use solutions for designing and documenting electrical control systems, servos, terminal plans, and PLCs. It provides an intelligent design to understanding the operators work with help eliminating errors, improving quality and reducing design time.

A feature called E3.panel provides easy component layout and snapping point capabilities that makes designing the layout easier to use. It virtually represents the electronics within the mechanical apparatus for space awareness. It is fully integrated with E3.schematics so the items can be navigated in either feature. Signal logic is directly transferred from the wiring schematics and implemented in the virtual CAD in the E3.panel feature. They provide the following benefits.

|

E3.SCHEMATIC |

E3.PANEL |

|

Device Duplication Prevention |

Drag and Drop Panel Model |

|

Short Circuit Prevention |

Dynamic Links to Schematic |

|

Automatic Parallel Connections |

Slot and Mount Functionality |

|

Intelligent Components Library |

Automatic Wire Routing |

|

User Defined Attributes |

Wire Segregation |

|

Ensure on Valid Part Usage |

3D Visualization |