Modern Electrical Engineering

10 Most Common Mistakes in Electrical Design Software

Device name duplication early in design, broken links for cross-referencing between components, and time consuming component generation, these are just some of the mind numbing errors that happen when generating an electrical design in low quality CAD software. These mistakes that take an enormous amount of your time to fix, are just the tip of the iceberg. This article will dive into the wonderful calamities that all electrical engineers eventually run into. And just for fun let us make it the 10 Most Common Mistakes in Electrical Design Software.

1. Blocks just don’t update with design changes, requiring manual checks just to make sure everything is functioning properly

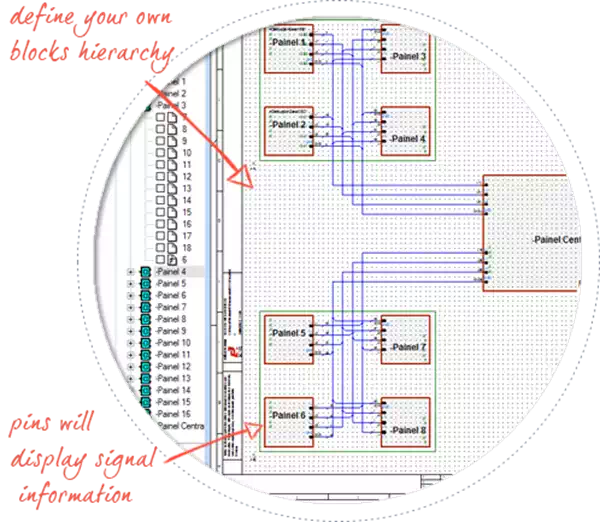

Block definition diagrams define the system structure and show the flow of information between system components. Blocks are components in the diagram and might include links inside a block, if the design changes and doesn’t update properly the design won’t function as planned.

Block and Pin Diagram

2. Wire numbers are automatic just until you make one small change to the drawing and then everything goes right back to manual entering

The main disadvantage with wire number schemes with no automatic addressing is if you need to add additional pages, reorganize, or adding lines you have to change the wire numbers for everything. This is where software for auto numbering benefits quite well, even after changes are made to the layout, the software will re-number each page accordingly, and best of all hassle free. If you have an installation that never changes then you are ok. Some people try to avoid this by creating additional pages at the start in order to anticipate possible changes. But, if you install changes regularly, then this is problematic.

3. Reference linking is fine as long as they never move or change them

Reference links, or designators, identify components in electrical schematics or PCB and for this reason cannot be duplicated. If the reference link is changed or moved the reference naming system must have the ability to automatically organize the project accordingly.

4. Lack of library components resulting in time wasted customizing your own

Initially the library capabilities on some CAD software was not intended for repeated use. It provides the bare necessities, which wasn’t much, and was under the assumption that those electrical designers would create their own symbols and reuse them. Many CAD software companies state that they offer libraries, but not all live up to the claim. Many companies provide a limit on resources when providing libraries for designers to use. This assumption was done with the intent that designers would have highly specialized designs that common components could not replicate easily too. This gives designers the ability to develop their own library and prepare it for how products will be designed later on for their own needs. Database libraries that are stored with preloaded designs can be convenient, but in today’s society many of the devices created are customized and not determined from common pre-existing designs.

5. Simple copy/paste commands are rendered useless

Making people resort to having to manual remake each sub-assembly over and over again.

6. Drawing a document ordering list that automatically fills with nothing

Most CAD software gives the user freedom to develop their own documentation. This gives always flexibility for the bill of materials and ordering list. The drawback for creating your own documentation is that the entry section has to be filled manually. Some companies have automatic documentation generated by simply clicking a button. This means less time spent going through pages of the project and updating its current status whenever changes are made.

7. Lack of built-in IEC and ANSI symbols in library

Many built in library have limited standard symbols, let alone many symbols to begin with. Software that allows the use of different stand symbols and auto checks that the design is possible would make life simpler.

8. No easy to use simple drag and drop interface

Creating your own design is a pain and can drain the person’s soul from repeating this action too often. A simple interface where previous components are easily saved and utilized in future events would be beneficial for designers. The components would not have to be redone again, just to re-install another sub-assembly, instead of an easy to function drag and drop interface. Many companies provide many features that are preloaded with utilities that designers commonly use. These can range from the simply generic, to the overly complex solutions. Self created libraries provide a means for companies to save previous models and reuse them again for other relative applications. This provides a quick and easy utility that can save on hours of design work in the future.

9. Tediously having to connect every single wire connection manually

When the schematic contains numerous amounts of wires for each component, this becomes a difficult and erroneous task. Not to mention that each wire has to follow certain paths in order to avoid interference with other components, leading to multiple straight line deviations. Modern CAE software creates all those connections automatically for the user, while automatically choosing the shortest path, while respecting how much a specific wire can bend without breaking and also making sure there is enough room for those wires to fit. You can even define custom limits (e.G.: Only use a top 80% of available space, to allow for future modifications).

10. Wire connections breaking by simply moving the device anywhere

Removing/moving any component already wired up in CAD, will result in connection lost and require the device be re-wired again. Drag/dropping a device within the platform, without the use of re-wiring everything again, is possible in modern software’s, and allows for automatic connectivity between existing terminals, specially in cases where the designer has a large amount of connections to redo.