Core design - Design of Transformers

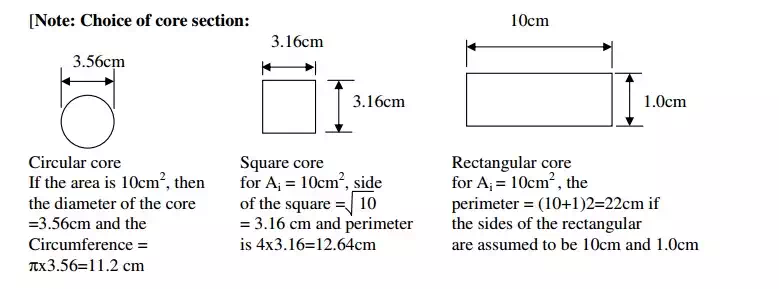

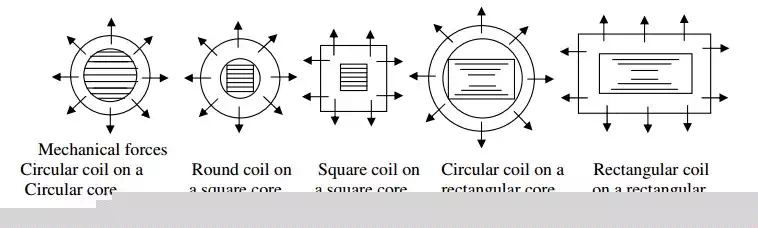

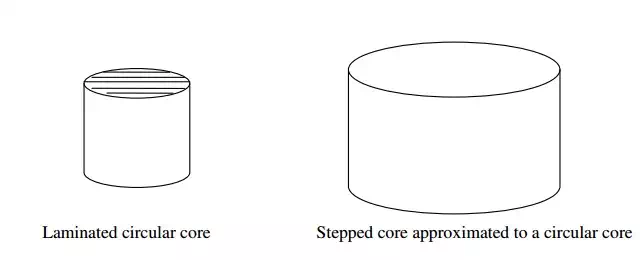

Net iron area of the leg or limb or core Ai. For a given area Ai, different types of core section that are used in practice are circular, rectangular and square.

Core design

Net iron area of the leg or limb or core Ai

For a given area Ai, different types of core section that are used in practice are circular, rectangular and square.

It is clear that the rectangular

core calls for more length of copper for the same number of turns as compared

to circular core. Therefore circular core is preferable to rectangular or

square core.

Very high

values of mechanical forces under short circuit conditions tries to deform the

shape of the square or rectangular coil (the mechanical forces try to

deform to a circular shape) and hence damage the coil and insulation.

Since this is not so in case of circular coils, circular coils are preferable

to square or rectangular coils.

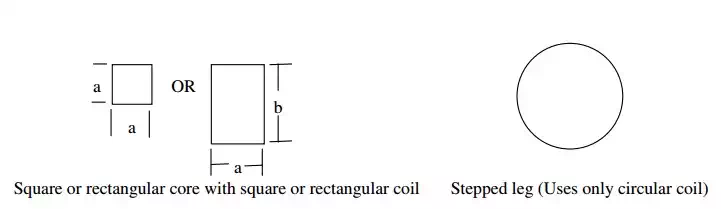

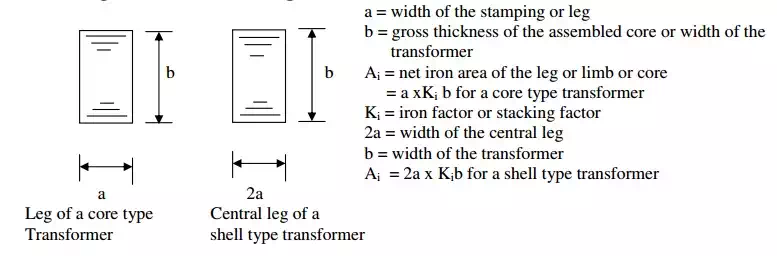

Leg or limb section details: -

The different

types of leg sections used are rectangular, square and stepped.

a = width

of the stamping or leg

b = gross

thickness of the assembled core or width of the transformer

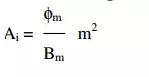

Ai = net

iron area of the leg or limb or core

= a xKi b for a core type

transformer

Ki = iron factor

or stacking factor

2a = width

of the central leg

b = width

of the transformer

Ai = 2a x Kib for a shell type

transformer

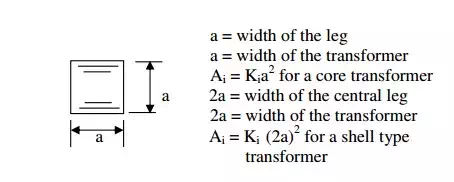

(a) Square core (with a square coil)

a = width of the

leg

a = width of the

transformer

Ai =

Kia2 for a core transformer

2a = width of the

central leg

2a = width of the

transformer

Ai =

Ki (2a)2 for a shell type transformer

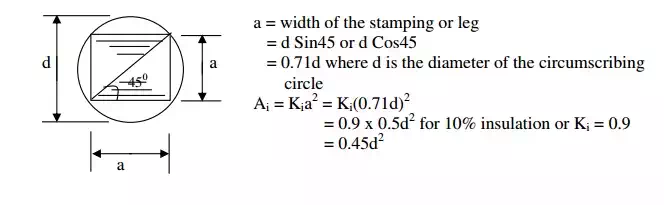

(b) Square core (with a circular coil)

a = width of

the stamping or leg

= d Sin45

or d Cos45

= 0.71d

where d is the diameter of the circumscribing circle

Ai =

Kia2 = Ki(0.71d)2

= 0.9 x

0.5d2 for 10% insulation or Ki = 0.9

= 0.45d2

Area of the

circumscribing circle Ac = πd2/4 = 0.785d2

It is clear that

Ai is only 57.3% of Ac. Rest of the area 42.7% of Ac is not being utilized

usefully. In order to utilize the area usefully, more number of steps is

used. This leads to 2 stepped, 3 stepped etc core.

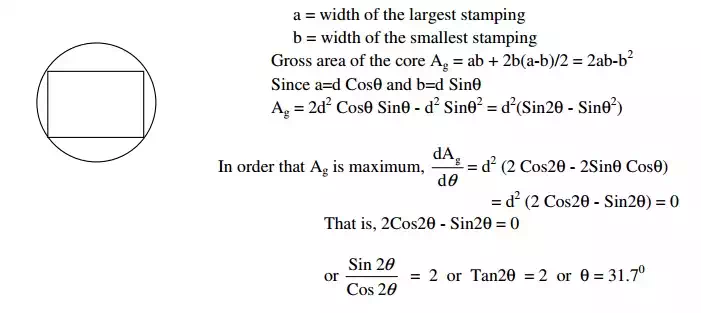

Cruciform or 2-stepped core:

a = width of the largest

stamping

b = width of the

smallest stamping

Gross area of the

core Ag = ab + 2b(a-b)/2 = 2ab-b2

Since a=d

Cosθ and b=d Sinθ

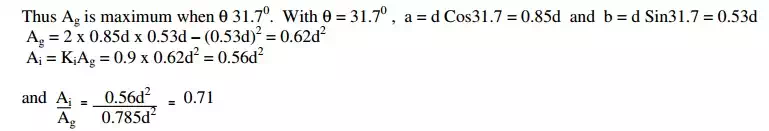

It is clear

that addition of one step to a square core, enhances the utilization of more

space of the circumscribing circle area.

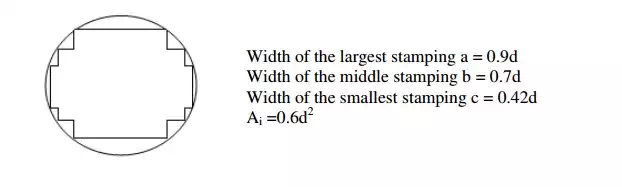

Three stepped core:

Width of

the largest stamping a = 0.9d

Width of

the middle stamping b = 0.7d

Width of

the smallest stamping c = 0.42d

Ai =0.6d2

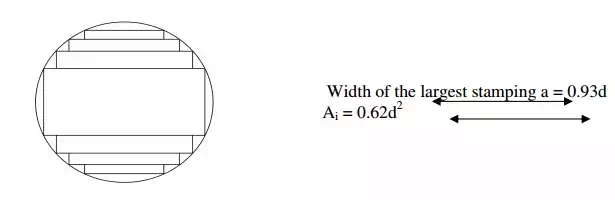

Four stepped core:

Note : As the number of steps increases, the diameter of the

circumscribing circle reduces. Though the cost of the core increases,

cost of copper and size of the coil or transformer reduces.

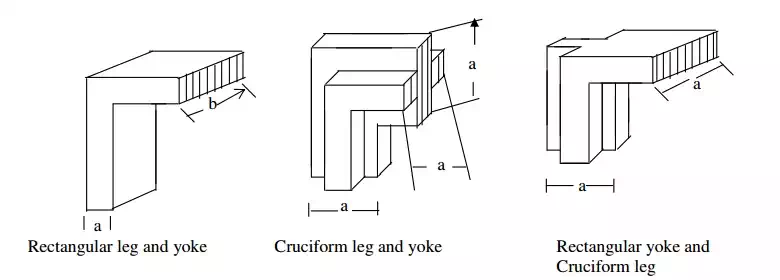

Yoke section details:

The purpose

of the yoke is to connect the legs providing a least reluctance path. In order

to limit the iron loss in the yoke, operating flux density is reduced by

increasing the yoke area. Generally yoke area is made 20% more than the

leg area..

Note:

1. Whenever the yoke

area is different from the leg area, yoke can considered to be of

rectangular type for convenience.

The different types

of yoke sections used are square, rectangular and stepped.

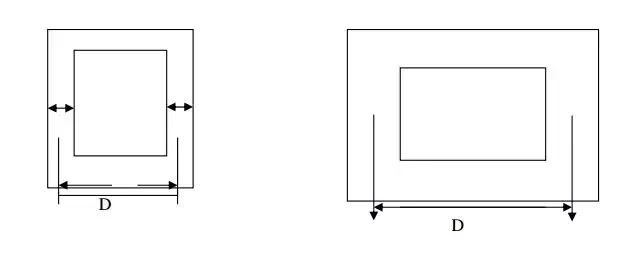

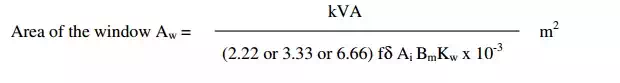

Window area and core proportion

If Hw = height of the

window, Ww =

width of the window, then Aw = HwWw

In order to limit

the leakage reactance of the transformer, Hw is made more than Ww. In practice Hw / Ww lies between 2.5 and 3.5.