Control

Engineering

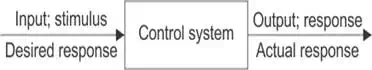

Control system engineering focuses on analysis and design of

systems to improve the speed of response, accuracy and stability of system. The

two methods of control system include classical methods and modern methods. The

mathematical model of system is set up as first step followed by analysis,

designing and testing. Necessary conditions for

the stability are checked and finally optimization follows.

In

classical method, mathematical modeling is usually done in time domain,

frequency domain or complex s domain. Step response of a system is

mathematically modeled in time domain differential analysis to find its

settling time, % overshoot etc. Laplace

transforms are

most commonly used in frequency domain to find the open loop gain, phase

margin, band width etc of system. Concept of transfer function, sampling of

data, poles and zeros, system delays all comes under the classical

control engineering stream.

Modern control engineering deals with Multiple Input Multiple

Output (MIMO) systems, State space approach, Eigen values and vectors etc.

Instead of transforming complex ordinary differential equations, modern

approach converts higher order equations to first order differential equations

and solved by vector method.

Automatic control systems are most commonly used as it does not involve manual

control. The controlled variable is measured and compared with a specified

value to obtain the desired result. As a result of automated systems for

control purposes, the cost of energy or power as well as the cost of process

will be reduced increasing its quality and productivity.

Historical Review of Control Engineering

The application of Automatic control system is believed to be in use even from

the ancient civilizations. Several types of water clock were designed and

implemented to measure the time accurately from the third century BC, by Greeks

and Arabs. But the first automatic system is considered as the Watts Fly ball

Governor in 1788, which started the industrial revolution. The mathematical

modeling of Governor is analyzed by Maxwell in 1868. In 19th century,

Leonhard Euler, Pierre Simon Laplace and Joseph Fourier developed different

methods for mathematical modeling. The second system is considered as Al Butzís

Damper Flapper - thermostat in 1885. He started the company now named as

Honeywell.

The

beginning of 20th century is known as the golden age of control

engineering. During this time classical control methods were developed at the

Bell Laboratory by Hendrik Wade Bode and Harry Nyquist. Automatic controllers

for steering ships were developed by Minorsky, Russian American Mathematician.

He also introduced the concept of Integral and Derivative Control in 1920s.

Meanwhile the concept of stability was put forward by Nyquist and followed by

Evans. The transforms were applied in control system by Oliver Heaviside.

Modern Control Methods were developed after 1950s by Rudolf Kalman, to overcome

the limitation of classical Methods. PLCís were introduced in 1975.

Types of Control Engineering

Control engineering has its own categorization depending on the different

methodologies used, which are as follows.

1. Classical

Control Engineering : The systems are usually represented by using ordinary

differential equations. In classical control engineering, these equations are

transformed and analyzed in transformed domain. Laplace transform, Fourier transform and z transform are

examples. This method is commonly used in Single Input Single Output systems.

2. Modern Control Engineering

: In

modern control engineering higher order differential equations are converted to

first order differential equations. These equations are solved very similar to

vector method. By doing so, many complications dealt in solving higher order

differential equations are solved. These are applied in Multiple Input Multiple

Output systems where analysis in frequency domain is not possible.

Nonlinearities with multiple variables are solved by modern methodology. State

space vectors, Eigen values and Eigen Vectors longs to this category. State

Variables describe the input, output and system variables.

3. Robust Control Engineering

: In

robust control methodology, the changes in performance of system with change in

parameters are measured for optimization. This aids in widening the stability

and performance, also in finding alternate solutions. Hence in robust control

the environment, internal in accuracies, noises and disturbances are considered

to reduce the fault in system.

4. Optimal Control Engineering : In optimal

control engineering, the problem is formulated as mathematical model of

process, physical constraints and performance constraints, to minimize the cost

function. Thus optimal control engineering is the most feasible solution for

designing a system with minimum cost.

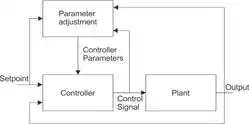

5. Adaptive Control Engineering

: In

adaptive control engineering, the controllers employed are adaptive controllers

in which parameters are made adaptive by some mechanism. The block diagram

given below shows an adaptive control system.

6.

In this kind of controllers an additional loop for parameter adjustment is

present in addition to the normal feedback of process.

7. Nonlinear

Control Engineering : Non linear control engineering focuses on the non

linearityís which cannot be represented by using linear ordinary differential

equations. This system will exhibit multiple isolated equilibrium points, limit

cycles, bifurcations with finite escape time. The main limitation is that it

requires laborious mathematical analysis. In this analysis the system is

divided into linear part and non linear part.

8. Game Theory

: In

game theory, each system will have to reduce its cost function against the

disturbances / noises. Hence it is a study of conflict and co operation. The

disturbances will try to maximize the cost function. This theory is related to

robust and optimal control engineering.