Modelling the

Pulse-Width Modulator

Pulse-width

modulation can be of many forms. A PWM signal of constant frequency can be

obtained by comparing the ramp signal (or carrier signal) with the error

between the desired and the actual output voltage signal (Vc,

compensator voltage signal).

Recommended Level

Beginner

Pulse-Width Waveform Generation and

Analysis of Important Parameters in Modelling PWM

Pulse-width modulation can be

of many forms. A PWM signal of constant frequency can be obtained by comparing

the ramp signal (or carrier signal) with the error between the

desired and the actual output voltage signal (VC ,compensator voltage signal).

Mathematically, PWM output is

δ(t) = sign (Vr (t) - VC (t)) [Equation 1]

where:

Vr is the ramp waveform generator output.

VC is the the compensator

voltage.

Sign

is a sign function which gives the binary output depending upon the difference

between Vr and VC.

δ(t) have the positive value when ramp voltage Vr is greater than VC , otherwise it is zero as shown in Fig. 2 and Fig. 3.

Vr is the reference or carrier signal

which can be a sawtooth, inverted sawtooth and triangular wave. Here, we have considered

the sawtooth or ramp signal for the

analysis.

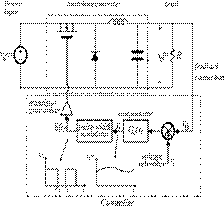

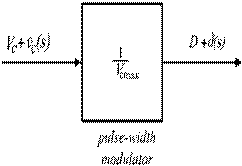

A typical voltage mode

control pulse-width modulator block diagram is shown in Fig.1

Figure 1.

Voltage Mode Control PWM Modulator

Peak amplitude of the ramp

wave is VP. A comparator compares the output

voltage VO and ramp voltage Vrto generate the switching variable δ(t)

as shown in Fig. 2 and Fig. 3. There are two cases shown for generating the

signal δ(t) depending upon the switching

instance at the start or end of the cycle.

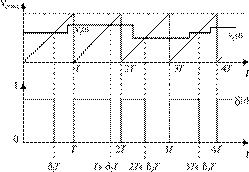

Figure 2. PWM

Waveform Generation with Turning-On at the Start of Cycle

From Fig. 2, ramp signal is

represented by the equation:

Vr(t)=VcmaxtTVr(t)=VcmaxtT

δc can be obtained at the intersection of Vr and VC ,

thus,

Vr(δcT)=VcmaxδcTT=VCVr(δcT)=VcmaxδcTT=VC

⇒δc=VCVcmax⇒δc=VCVcmax

Where c = 0, 1, 2,….. n [Equation 2]

Therefore, the gain of the

compensator is

GC=δcVC=1Vcmax.GC=δcVC=1Vcmax.

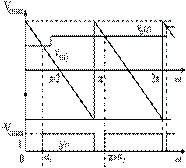

Figure 3. PWM

Waveform Generation with Turning-Off at the End of Cycle

From Fig. 3, we need to find

out the value of switching angle i.e. αc where c = 0, 1, 2…..n.

Here, ramp signal can be

expressed as:

Vr(t)=Vcmax−2VcmaxwtπVr(t)=Vcmax−2Vcmaxwtπ

And error signal as:

VC(t)=Vcmax−2VcmaxαcπVC(t)=Vcmax−2Vcmaxαcπ

At the intersection point, VC = Vr

αc=π2(1−VCVcmax)αc=π2(1−VCVcmax)

[Equation 3]

Thus, the gain of the

compensator is

GC=dαcdVC=−π2Vcmax.GC=dαcdVC=−π2Vcmax.

After turning on and off any

variation in the compensator signal VC(t), the duty cycle δ(t) will be

affected after some delay. Let us say that the value of this delay is T/2.

Then the control transfer

function can be expressed

as,

δc(t)vc(t)=Gce−sT2=GC1+sT2+s22!(T2)2+…≈GC1+sT2δc(t)vc(t)=Gce−sT2=GC1+sT2+s22!(T2)2+…≈GC1+sT2

Clearly, this pole occurs at

the frequency which is double of the switching frequency. As the location for

frequency of the state-space average models is near about one decade of the

switching frequency, compensator pole can be neglected.

For DC-to-DC converter, PWM

reference signal (Vr) is of constant value and independent

of modulation technique employed for the steady state. For the dynamic purpose,

the reference signal can be considered to be the sum DC value corresponding to

the steady state and a sinusoidal signal signifying the small signal

perturbation.

Mathematically, it can be

written in general as,

Vr(t)=Vro+Vr1cos(2πf1t+∅1)Vr(t)=Vro+Vr1cos(2πf1t+∅1)

Where f1 is the frequency of the reference

signal.

Previously, LTI model that

characterizes the small signal behavior of

a converter is required for analysis and controller design. This model can be

developed for both constant frequency and variable frequency pulse-width

modulation. Here, we are going with the constant PWM.

Average duty ratio,

d=VroVcmaxd=VroVcmax

and

Modulation Index,

M=2Vr1VcmaxM=2Vr1Vcmax

The amplitude of the

perturbation

=Vr1Vcmax=M2=Vr1Vcmax=M2

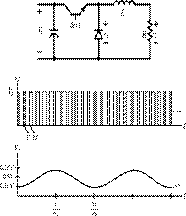

An example of buck converter

is shown in Figure 4. If we alter the duty ratio slowly as compared to the

switching frequency, we will get a waveform whose average values change with

time. Thus, we need to do averaging for this case. The averaging time must be

greater than the switching time but less than the rate of change of the duty

cycle.

The duty ratio is altered to

get a load voltage having a DC component and a sinusoidal frequency, wa, whose value is lesser than the

switching frequency.

The modulated d(t) in that case can be represented

as,

d(t)=0.5+0.25sinwatd(t)=0.5+0.25sinwat

Figure 4. Buck

Converter with Modulated Duty Ratio

As we have studied earlier in

the cases of buck, boost and buck-boost converters, either switch or diode

conducts at a particular time in continuous conduction mode; and expressed

as

x˙=[A01δ(t)+A02(1−(δ(t))]x+[B01δ(t)+B02(1−δ(t))]ux˙=[A01δ(t)+A02(1−(δ(t))]x+[B01δ(t)+B02(1−δ(t))]u

But this model is not

acceptable to design linear control systems as it has a time-varying

function δ(t) which is multiplied by the

state variables. Thus, we have to deal with this time-varying problem with

averaging. The state-space averaging model obtained over a switching cycle will

be

x¯¯¯˙=[A01d+A02(1−d)]x¯¯¯+[B01d+B02(1−d)]u¯¯¯x¯˙=[A01d+A02(1−d)]x¯+[B01d+B02(1−d)]u¯

Similar equation can be

written for the output signal. Here, d is the algebraic

average of the duty cycle ratio over a complete cycle.

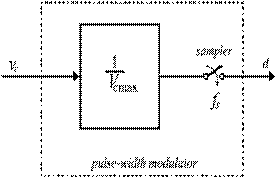

Consider that there is a

small disturbance in the controller compensator signal due to variation in the

output and the result in the duty cycle is shown by the block diagram below.

We now have,

VC(t)=VC+vˇc(t)VC(t)=VC+vˇc(t)

and

d(t)=D+dˇ(t)d(t)=D+dˇ(t)

Figure 5. Block

Diagram of the PWM for the Perturbation Case

From Equation 2, we have the

following PWM equation for the linear ramp signal:

δc=d=VCVcmaxδc=d=VCVcmax

for 0

≤ VC (t) ≤ Vcmax

It is clear from this

equation that δc(t) is linearly dependent on the VC.

Including the small signal,

the final PWM equation

is,

D+d(t)=VC+vˇc(t)VcmaxD+d(t)=VC+vˇc(t)Vcmax

If we separate the

steady-state relation and the small-signal relation, we get the following

results:

D=VCVcmaxD=VCVcmax

and

dˇ(t)=vcˇ(t)Vcmaxdˇ(t)=vcˇ(t)Vcmax

In Fig. 5, the input signal

is continuous while the output has discrete values. Thus, a sampler with

sampling rate equal to the switching frequency is needed as shown in Fig. 6.

Figure 6. PWM

Modulator

This model is valid for

continuous conduction mode. In the case of discontinuous conduction, we have to

consider the three intervals of switching to form the final model.

In the case of the voltage

control methodology for the small-scale linear model, the ratio of the duty

ratio to the output voltage will be in the second order. Crossover frequency

for the voltage control loop must be lower than the resonant frequency to

ensure the stability of the system. Also, there exist a right-half plane zero

in this transfer function even at frequencies that are less than the resonant

frequency. Thus, this model is accurate only for frequencies much lower

than fs /

2 (Nyquist rate). This issue can be solved by the adding a current-loop control.