DIY: How to Build a Hand Crank

Flashlight

A hand operated flashlight does

not need input from sources like wind or sun in order to generate electricity.

Just pressing a spring-gear mechanism is enough to make the device “pump"

electricity that can be used for activating an output load.

We have already learnt a lot

regarding white LEDs and their high efficiency with power consumption. We have

also seen how these outstanding devices can be used for decorating our homes or

illuminating our houses during power failures through battery back-ups for long

hours. White LEDs not only are power efficient, but are also able to produce

high intensities of light at nominal voltage levels. This particular feature

makes them truly versatile as now it becomes possible to illuminate them

through low and ordinary power sources like button cells or through motor

cranked mechanisms.

In this article we discuss a

simple hand-cranked LED lighting mechanism able to light up a single white LED

up to its maximum intensity. This hand cranked flashlight incorporates a geared

stepper-motor and an integrated electronic circuit; together the system is able

to generate sustained illuminations over the connected white LED. This source

of energy is continuous, renewable, and permanent.

Let’s get into the functioning

details of the unit.

Mechanical LED Flashlight Mechanism

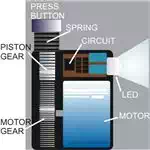

The generator uses a stepper motor

and an attached spring loaded crank mechanism. On pressing the crank button the

connected geared shaft and geared wheel mechanism integrated with the stepper

motor forces it to rotate with full momentum (anticlockwise), and releasing the

button forces the shaft to move upwards due the recoil effect of the spring.

This upward retraction of the shaft again forces the motor to rotate, but this

time in the clockwise direction, and the cycle reciprocates as long as the

piston is cranked through an external force (by human hand here). Unlike

ordinary motors stepper motors are able to generate huge induced voltages even

at nominal speeds making one an excellent choice for the present application.

The specified motor should be generating around 12 volts easily even at

ordinary rotational speeds.

The rotation of the internal

motor winding in between magnets induces a potential difference across its

windings constituting a flow of electricity. However, since the rotation of the

motor is bidirectional, this means that the generated electricity will be

changing its polarity every time its rotation is flipped. That’s true; in fact

the generated current is an AC which needs to be converted to DC before

applying it to the LED.

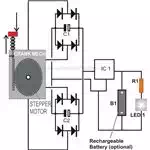

Two bridge rectifier networks

configured with the respective windings of the motor takes care of the above

and converts the generated AC to DC which is further smoothed by the adjoining

capacitors. The capacitors also function as storage devices so that even during

intermittent lapses in the cranking, the LED continues to glow at its maximum

intensity retrieving the stored energy from the capacitor.

The IC 7805 makes sure the LED

receives a controlled voltage of 5 volts and remains safe from sudden voltage

rises.

Parts Required

The entire system may be enclosed

inside a plastic housing as shown in the adjoining figure.

An optional battery may also be

incorporated if continuous operation of the LED is felt necessary.

The following parts will be

required for the construction of this generator:

Any Stepper Motor having a couple

of windings of more than 50 Ohms (DC resistance) each.

Current Limiting Resistor – 47

Ohm, Ľ watt, 5%, CFR,

Diodes 1N4007 – 8 nos.

Capacitor 2200µF/10V – 2 nos.

IC 7805 = 1 no.

LED White High Efficiency 5mm –

1no.

Crank mechanism parts as shown in

the diagram,

Small piece of general PCB,

Enclosure as illustrated in the

diagram.