How to Keep a Power

Transistor Cool Using a Heat Sink

Which devices generate heat?

With regard to circuits, the

broad answer to this question is – all of them. Heat in circuitry is caused by

resistance, a property found in every part of a circuit: wire, capacitors,

resistors, semiconductors, batteries, solder. Heat is the effect caused by

current traveling through a resistance in which power is lost to the

surrounding media in the form of a temperature increase. In many of these

components the heating is trivial; unless you are a power engineer, you

probably will not have to deal with keeping copper wire cooled with mineral

oil. However for some of these devices heat is a real issue that needs to be

addressed-- in particular the heat generated by semiconductors.

Analog

In analog applications

of semiconductors, heat will most often be encountered in voltage regulators

and output transistors. With regulators, the power lost to heat is pretty easy

to conceptualize: if you have a 12 Volt supply and wish do generate an output

of 5 Volts using a regulator, then with a circuit drawing one Amp of output

current, the regulator has 12 Watts going into the device, and 5 Watts coming

out. What happened to the other 7 watts? They have been burned off in the form

of heat; we will come back to this example when talking about dissipating this

heat.

On to output transistors- in

an ideal world, transistors do not dissipate power when they are fully on or

fully off. To illustrate this we can use the classic example of an ideal switch:

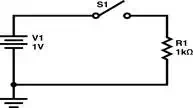

Case 1: Switch

Open

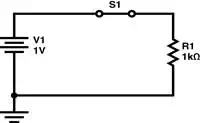

Case 2: Switch

Closed

In case 1, the switch is an

open circuit and no current may flow through the switch or the resistor because

we have from Ohm’s law that:

![]()

Now in case 2, the switch has

been closed and now there is 1mA of current flowing through the switch and

resistor. Now that there is current through our switch, let’s look at how much

power it is dissipating. We know that an ideal closed switch is a perfect

conductor, i.e. presenting no resistance; so our equation for power dissipated

by the switch becomes![]()

Thus, no power is dissipated

by the switch in either the closed or open cases. However in real life we are

not using ideal components: BJT’s have a VCE_Sat usually

around 0.2 Volts when fully on and even MOSFETs have a small resistance RDS_On when fully on. For most cases these values are

low enough that the power dissipated is very low; it is the state between off

and on that dissipates the most power. In a power handling device such as an

audio power amplifier, transistors will amplify sinusoidal waveforms to be

delivered into a low impedance load, usually a speaker.

A properly biased Class

– A output (one that is operating for the

entire 360 degree wave cycle) will have this output transistor constantly

transitioning between off and on, never quite reaching either, in a sinusoidal

pattern mimicking that of the input. Thus a Class –A amp

will dissipate the most power with zero signal applied, because at this point

the transistor will be exactly halfway between the off and on states. This is

important to note, because the power dissipated during the zero input condition

is what will be used to determine the size of heatsink needed to keep the

transistors from overheating. A Class – B output (in which each output device

operates for exactly half of the wave cycle) will generate much less heat, as

it spends half its time in the fully off state to which it is biased. In this

case the amplifier dissipates the least amount of power as heat in the zero

input signal condition, making Class – B amplifiers more thermally efficient

than Class – A.

Digital

In digital applications of

semiconductors, the goal is to switch between on and off states at the clock

frequency, spending no time in between and thus dissipating no power. Once

again we run into the issue that these devices are not perfect; for a given

CMOS transistor there is a minimum transition time based on the dimensions and

parasitic capacitances of the physical device which limits how fast it can

switch between off and on. During this transition time, the device will be

dissipating power in the form of heat. When the clock speed of a digital chip is

increased, the time spent in either off or on states decreases but the

transition time remains the same. Thus as the speed increases, the ratio of

steady-state to transition-state decreases and more power is lost to heat. This

is one of the primary reasons that over-clocking a computer’s CPU usually

requires greater measures to be taken to cool the chip.

Beating the Heat

Now we know how and why

devices dissipate heat, so how do we control it? Just as there are good

conductors of electricity, there are good conductors of heat. Materials such as

copper and aluminum are excellent

conductors of heat and are used as devices called heatsinks to help move heat

from a semiconductor to the air quickly, preventing thermal damage to the chip.

The more surface area a heatsink has, the faster it can transfer heat to the

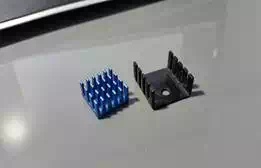

air. The picture below depicts a pair of heatsinks; the fins on the heatsinks

are what increase the surface area.

The comparison of electrical

conductors to heat conductors is no accident, and the equations governing both

are analogous: Ohm’s Law --> Voltage = Resistance * Current Temperature Rise

--> delta Temperature = Thermal Resistance * Power Dissipation or, using the

standard variable designations:![]()

For example, the voltage

regulator from earlier was giving us 5 Volts from a 12 Volt supply at 1 Amp,

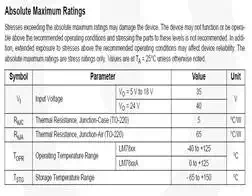

dissipating 7 Watts in so doing. A LM7805 would be a typical device that would

accomplish this, but what kind of heatsink do we need to help the regulator

dissipate that 7 Watts? Checking the datasheet for the LM7805 (available via a

quick Google search) we see that the thermal resistance from the semiconductor

junction to the external case of the device is 5 degrees Celsius per Watt, and

the resistance from junction to ambient air is 65 degrees Celsius per Watt.

Using our temperature

equation and the specifications from the datasheet we see that:

![]()

![]()

![]()

Thus the MINIMUM thermal

resistance we need in a heatsink will be 9.29 C/W; however in engineering we

always want to give ourselves a margin of error, in this case lets go with 20%. This means we actually need to find a

heatsink with a thermal resistance of not more than 7.43 C/W. At this point we

can go to an electronics part distributor website such as Mouser or Digikey and search for heatsink that will fit a TO-220

case and have the right thermal resistance. I quickly found part No.

532-504222B00 from Mouser which has a thermal resistance of 6.4 C/W; this will

work perfectly for our application. When attaching the heatsink it is important

to use thermal compound between the case and heatsink. This is because it will

fill up any tiny pockets of air that may be between the two and cause an

increase in thermal resistance- we definitely don't want that.

Heat is something any

engineer, regardless of discipline, will encounter in their career. It is

important to recognize the limitations of your hardware and be able to

compensate using the appropriate heatsink. Datasheets will always be your

friend as you crunch numbers to try and discern what the best course of cooling

will be in your particular situation, and remembering to give yourself a margin

of error will set you up for success.