DC

Motor or Direct Current Motor

What is DC Motor ?

Electrical motors are everywhere

around us. Almost all the electro-mechanical movements we see around us are

caused either by a AC or a DC motor.

Here we will be exploring DC motors. This is a device that converts DC

electrical energy to a mechanical energy.

Principle of DC Motor

This DC or direct current motor works on the

principal, when a current carrying conductor is placed in a magnetic field, it experiences a

torque and has a tendency to move.

This is

known as motoring action. If the direction of current in the wire is reversed,

the direction of rotation also reverses. When magnetic field and electric field

interact they produce a mechanical force, and based on that the working

principle of DC motor is established.

The direction of rotation of a this motor is given by Fleming’s left hand rule,

which states that if the index finger, middle finger and thumb of your left

hand are extended mutually perpendicular to each other and if the index finger

represents the direction of magnetic

field,

middle finger indicates the direction of current, then the thumb represents the

direction in which force is experienced by the shaft of the DC motor.

Structurally

and construction wise a direct current motor is

exactly similar to a DC

generator,

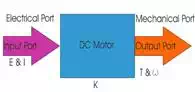

but electrically it is just the opposite. Here we unlike a generator we supply

electrical energy to the input port and derive mechanical energy from the

output port. We can represent it by the block diagram shown below.

Here in a DC motor, the supply voltage E and current I is given to

the electrical port or the input port and we derive the mechanical output i.e.

torque T and speed ω from the mechanical port or output port.

The input

and output port variables of the direct current motor are related by

the parameter K.

![]()

So from the picture above we can well understand that motor is just the

opposite phenomena of a DC

generator,

and we can derive both motoring and generating operation from the same machine

by simply reversing the ports.

Detailed Description of a DC Motor

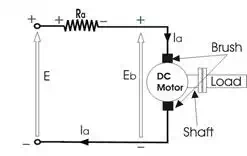

To understand the DC motor in details lets consider

the diagram below,

The direct current motor is

represented by the circle in the center, on

which is mounted the brushes, where we connect the external terminals, from

where supply voltage is given. On the

mechanical terminal we have a shaft coming out of the Motor, and connected to

the armature, and the armature-shaft is coupled to the mechanical load. On the

supply terminals we represent the armature resistance Ra in

series. Now, let the input voltage E, is applied

across the brushes. Electric current which

flows through the rotor armature via brushes, in presence of the magnetic field, produces a

torque Tg . Due to this

torque Tg the dc motor armature

rotates. As the armature conductors are carrying currents and the armature

rotates inside the stator magnetic

field, it

also produces an emf Eb in

the manner very similar to that of a generator. The generated Emf Eb is directed

opposite to the supplied voltage and is known as

the back Emf, as it counters the forward

voltage.

The back emf like in case of a generator is

represented by

![]()

Where, P = no of poles

φ = flux per pole

Z= No. of conductors

A = No. of parallel paths

and N is the speed of the DC Motor.

So, from the above equation we can see Eb is

proportional to speed ‘N’. That is whenever a direct current motor rotates,

it results in the generation of back Emf.

Now lets represent the rotor speed by ω

in rad/sec. So Eb is

proportional to ω.

So, when the speed of the motor is reduced by the application of load, Eb decreases. Thus the voltage difference between supply voltage and back emf increases that means E − Eb increases. Due

to this increased voltage

difference,

armature current will

increase and therefore torque and hence speed increases. Thus a DC Motor is

capable of maintaining the same speed under variable load.

Now armature current Ia is represented by

![]()

Now at starting,speed ω

= 0 so at starting Eb = 0.

![]()

Now since the armature

winding electrical resistance Ra is small, this motor has a very high

starting current in the

absence of back Emf. As a result we need to use

a starter for starting a DC Motor.

Now as the

motor continues to rotate, the back Emf starts

being generated and gradually the current decreases

as the motor picks up speed.

Types of DC Motors

Direct motors are named according to the connection o the

field winding with the armature. There are 3 types:

1. Shunt wound DC motor

2. Series wound DC motor

3. Compound wound DC motor