Understanding Inductor

Designs for Converters

A demonstration of filter inductor design

for boost converters, design of the coupled inductor for a two-output forward

converter, and the design of flyback transformer

in continuous conduction mode.

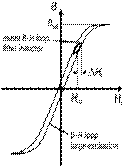

The filter inductor in the

converter circuit is operated in a small B-H loop region as compared to the

wide region for the conventional transformer. The area of B-H loop is

proportional to the total current ripple in the inductor. The core losses are

negligible, according to the minor B-H loop area. On the other hand, copper

loss depends on the DC current flowing through inductor. The same curve is also

applicable in the case of coupled inductor. Design is majorly constrained by

the copper loss and the saturation condition of the filter inductor.

Figure 1. B-H

Loop for Filter Inductor

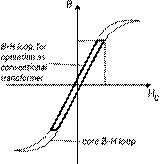

Figure 2. B-H

loop for the Conventional Transformer

Design of an Inductor for Boost Converter

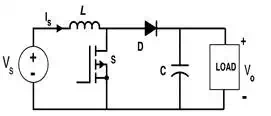

The circuit diagram of the

boost converter with related waveform under CCM:

Figure 3.

Circuit of Boost Converter

The basic constraints for the

design of an inductor are (a) keep the flux density B below the flux density at

the saturation BSAT (b) keep the temperature of the inductor within limit. We also

want the inductor current ripples to be equal to the ∈

part of the inductor current.(Ripples in the Inductor

<< Inductor Current)

We should know the

requirements for this converter circuit according to the following given

specifications:

VS, VO, f, PO

Where,

VS = Input Voltage

VO = Output Voltage

f

= Operating frequency in kHz. (f=1T)

PO = Output power in kW

We can get the duty ratio of

the boost converter by this equation:

D=VO−VSVOD=VO−VSVO

The input DC current of the

converter is the inductor current which is given by this equation:

IL=IS=IO1−D=POVO1−DIL=IS=IO1−D=POVO1−D

We have seen earlier that,

Imin=DVSR(1−D)2−VS2LDT=Iavg−∆ILImin=DVSR(1−D)2−VS2LDT=Iavg−∆IL

Imax=DVSR(1−D)2+VS2LDT=Iavg+∆ILImax=DVSR(1−D)2+VS2LDT=Iavg+∆IL

Thus,

∆IL=VS2LDT∆IL=VS2LDT

[Equation

1]

Also,

∆IL=∈IL∆IL=∈IL

[Equation

2]

Thus, the required inductance

value from Equations 1 and 2 is given by

L=VSDT2∈ILL=VSDT2∈IL

R.M.S value of the inductor

current in the case of a triangular wave is given by the following expression:

(ILrms)2=(Iavg)2+112(Ipp)2=(Iin)2+112(∆I)2(ILrms)2=(Iavg)2+112(Ipp)2=(Iin)2+112(∆I)2

⇒ILrms=(ILdc)2+112(2∆IL)2−−−−−−−−−−−−−−−−−√⇒ILrms=(ILdc)2+112(2∆IL)2

R.M.S value of voltage across

inductor is given by

VLrms=DVS2+(1−D)(VO−VS)2−−−−−−−−−−−−−−−−−−−−−√VLrms=DVS2+(1−D)(VO−VS)2

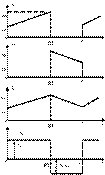

Figure 4. Supply

Current, Diode Current, Inductor Current and Inductor Voltage respectively

(Boost Converter)

If the frequency of the

converter is not less than the apparent frequency obtained from the following

expressions, it is a worst-case frequency.

fapparent=VLrms2πLfapparent=VLrms2πL

is valid for the low-frequency range under low eddy

current losses and d<1.6δ. Consider the fill factor FC according to the

type of conductor (round wire or litz wire).

Now, we have all the input parameters in designing an inductor. We can

determine the core parameters AC', AW, and lmeanT using the constraint

equations below.

NIm≈BmAC′Rg=BmAC′lgμONIm≈BmAC′Rg=BmAC′lgμO

Rw=ρlwrAC=ρNlmeanTACRw=ρlwrAC=ρNlmeanTAC

L=N2Rg=µOAC′N2lgL=N2Rg=µOAC′N2lg

FCAW≈NACFCAW≈NAC

We will then get the required

final volume of the core. We can now also multiply the volume with the

corresponding power density of the material at a particular frequency to

measure core loss. Power density is measured by the plot between the power

density at a particular frequency and the change in the magnetic flux density

given by the manufacturer. Change in flux density is given by:

∆B=VLN1AC′(DT)∆B=VLN1AC′(DT)

We can neglect the core loss

if it is comparatively less than the copper loss, and use the material which

has higher core loss and high saturation flux density. This leads to a smaller

size inductor core.

Design of a Coupled Inductor for a

Two-Output Forward Converter

Coupled inductors have

multiple windings wound on the same core for high value of inductance in common

mode current while low value of inductance for the differential mode current.

Coupled inductors have lower leakage inductance and AC current losses. Consider

a coupled inductor as shown in the figure below:

Figure 5.

Coupled Inductor

The number of turns for L1and L2 must be same to maintain the volt-time balance condition.

Magnetizing field is produced by the sum of the currents i.e. i1+i2 which flows through the core. Leakage field is produced by the

difference of the currents i.e. i1-i2 which flows through

air. The circuit diagram for the two-output forward converter using

coupled inductor is given below.

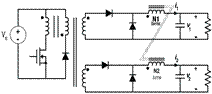

Figure 6.

Circuit for the Two-Output Forward Converter

Common Mode Current,

ic=i1+i22ic=i1+i22

Differential Mode Current,

id=i1−i22id=i1−i22

These currents both

contribute in the eddy current losses.

Common Mode Inductance,

Lc=N2Rm=PmN2Lc=N2Rm=PmN2

Differential Mode Inductance,

Ld=N2RO=PON2Ld=N2RO=PON2

Here, Pis the permeance provided

by the manufacturer and R is the reluctance. For common mode current, coupled

inductors act like two inductors L1and L2 in parallel. For differential

mode, coupled inductors act like a transformer. There is a considerable DC

component in the current flowing through L1and L2 which causes the net magnetization

of the core.

H(t)=N1i1(t)+N2i2(t)lCRmRm+ROH(t)=N1i1(t)+N2i2(t)lCRmRm+RO

Similar design procedure with

the single-winding filter inductor is used.

Design of a Flyback Transformer

in CCM

The flyback transformer

acts as an inductor, having two windings where only one of its windings carries

the current at a particular time. The flyback transformer

stores the energy and releases it later, which requires an air gap. As both the

windings carry the current alternatively even with the continuous total

ampere-turns, high AC winding losses are associated with the flyback converter irrespective of its operating

mode. Core loss depends on the magnetizing current Im for the transformer and is usually significant in the

case of the discontinuous conduction mode.

In CCM, conversion ratio for

the converter is:

VOVS=D1−D.VOVS=D1−D.

For the desired duty cycle

and nominal supply voltage, the initially expected turns ratio

is given by:

n=vsvo′D1−D=N1N2n=vsvo′D1−D=N1N2

where vo' is the sum of the voltages across

the load, switch, rectifier and copper loss referred to the secondary side. We

even need to see the duty ratio for the worst-case current of the DC and AC

components. Duty cycle and turns ratio can be possibly altered to optimize the

design. We can select the particular material according to the proper

specifications with the help of the data sheet.

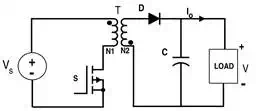

Figure 7.

Circuit for Flyback Converter

Core loss is negligible and

flux density is restricted by the saturation of the core. Net field in the core

is the sum of the magnetizing current and the leakage field. Magnetizing field

is used for the storage of energy and basically acts as an inductor while the

leakage field performs like a transformer.

Bn(t)=Bm(t)+Bl(t)Bn(t)=Bm(t)+Bl(t)

Change in Magnetic flux

density can obtained by

∆Bm=Bm∆ImIsc∆Bm=Bm∆ImIsc

Here, Isc is the short-circuit current

which produces the maximum flux density.

The number of turns on the

secondary side is given by

Ns=L∆Im∆BmAcNs=L∆Im∆BmAc

Thus, the corresponding turns

for the secondary can be calculated. Select the core shape and its type using

the guide provided by the manufacturer. Based on that, we need to calculate the

thermal resistance, conductor size, air gap length, winding loss, DC and AC

losses consequently.

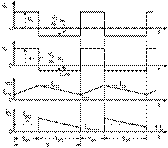

Figure 8.

Waveforms of Input Voltage, Output Voltage, Magnetizing Current, and Diode

Current for the Flyback Converter