Mad with Power: An

Introduction to Power Processing

The core

concept of power processing can be explained together with several significant

applications of power electronics. Power electronics is the technology of

processing and controlling the flow of electric power by modifying and

supplying the voltage and current in a form that is best suitable to the

customer at the load end.

Introduction to Power Processing

Power electronics is the

technology of processing and controlling the flow of electric power by

modifying and supplying the voltage and current in a form that is best suitable

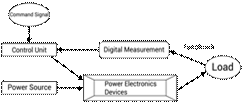

to the customer at the load end. A characteristic block diagram is shown in

Fig.1.

Power electronics is more

concerned with the electronics principles in the situations that are related at

a power level than at the signal level. This area of electronics

originated from the silicon-controlled Rectifier Evolution in 1956 by Bell

Laboratory. SCR technology led the breakthrough in power-handling capability of

electronic devices by making minor changes in the structure of signal electronics

devices. This led to high-performance semiconductor devices with better voltage

and current-handling capability which are currently used in different

applications such as in blowers, fans, AC, battery chargers, refrigerators,

dryers, HVDC transmissions, pf correction with static compensators, static

circuit breakers, relays, UPS, etc.Power electronics

amalgamates three major areas of electrical engineering: power, electronics,

and control, as shown in Fig. 1.

Fig.1

Representation of Major Components in Power Electronics System

The power source to the PE system may be a DC or AC supply,

depending upon the application or condition of that location. The output of the

PE system may be a variable AC or DC voltage or may be a variable voltage and

frequency. Thus, the power needs to be processed inbetween the

source and load. This is done with the help of a converter.

A failure in the converter

affects the users, and the loss in the converter is the loss in the overall

system. A converter must be reliable and must be made of components having a

negligible loss such as semiconductor switches.

The feedback component

measures the parameters of the load and compares it with a command signal. The

difference of the two serves as a basis for the turn-on and turn-off commands

of the power electronics device.

Thus, power electronics

processors can be majorly categorized according to their operation:

● AC to DC Converter (Rectifier)

● DC to AC Converter (Inverter)

● DC to DC Converter (Chopper)

● AC to AC Converter (Cycloconverter)

They can also be categorized

based on the turn-on and turn-off characteristics as well as the gate signal

requirement and the degree of controllability.

(a) Uncontrolled rectifying

devices (such as diodes): Their on and off state are dependent on the power

supply.

(b) Semi-controlled devices

(such as thyristor): They can be turned on by a

gate signal but its turn-off condition is dependent on the power circuit.

(c) Fully-controlled switches

(such as BJT, MOSFET, GTO and IGBT): These devices are turned on and turned off

by the application of control signals.

Applications of Power Electronics

Power electronics have

revolutionized innumberable control

techniques in both motor and non-motor applications, like the following:

(1) Induction motor

speed control. The speed of induction motor can be varied by AC

voltage control, voltage/frequency control, rotor resistance variation for

control, slip power recovery system control, etc. The cheapest method of

controlling the speed of the induction motor is to vary the applied voltage by

using an AC regulator in each line, consisting of the thyristors.

This is a voltage control method. V/f control is implemented with the

combination of rectifier/converter with an inverter. This inverter may be a

voltage-source inverter (VSI), a current-source inverter, (CSI) or an

impedance-source inverter (ZSI). Rotor resistance variation is a traditional

method employed for the speed control of induction motor, but this causes

sparking and other maintenance problems.

With the advancement of power

electronics, a static variation in the rotor resistance is implemented with the

help of a chopper in the rotor. Although a great improvement is achieved with

the help of a static variation of the rotor resistance, the better method for

speed control is the slip power recovery scheme, which is of course a power

electronics application. As in the rotor resistance controlled drive, the

efficiency is low as the slip power is dissipated in the external resistance.

This is more drastic at low speed or high-slip value. Closed loop systems named

as speed loop and current loop are usually used for better control and current

protection purposes.

(2) Induction motor

braking. There are three types of braking that employ the power

electronics circuitry to stop the running induction motor. These are called the

plugging, dynamic and regenerative braking. Aside from this, phase sequence can

also be reversed with the help of semiconductor switches.

(3) DC motor speed

control. The prime method for the speed control of DC motors is

armature control and field control. In armature control, armature voltage is

varied while keeping the field voltage constant. In the case of the field

control, the field voltage is varied while keeping the armature voltage

constant. Speed control below the base speed is obtained with the help of

armature control method while the speed control above the base speed is done

with the help of the field control method. Multi-quadrant operations including

forward motoring and generation, and reverse motoring and generation can be

obtained with the help of different schemes of converters. Speed can be varied

by varying the firing angle of the converter. Closed loop control

drive can also be used for a more precise and detailed control.

(4) DC motor braking. Similar

to the induction motor, DC machine can also be stopped with the help of

plugging, dynamic, and regenerative braking.

(5) Power Supply

Regulator. There are two types of DC power supply regulators:

conventional regulated power supply and the regulated power supply. These are

usually used in several applications such as in laboratories, electronics

circuits of medical equipment, etc. In the case of the conventional regulated

power supply, the AC supply available is stepped down to a lower level with the

help of a transformer and then rectified it into DC by a rectifier. It then

also needs to be stabilized by the help of a zener diode.

The main disadvantages of a

conventional voltage regulator are its bulky transformer and bulky inductor.

These disadvantages can be fixed with the help of a more advanced version of

the regulator called the switch-mode power supply (SMPS). Here, AC supply is

directly fed into the rectifier without a transformer. The DC output of the

rectifier is the input to the high-frequency inverter. The output of the

inverter is then stepped down to a low-voltage AC with the help of a

transformer. Now, this high-frequency low-voltage AC is rectified by a

rectifier and filtered by the use of L and C components. As the frequency in

the transformer increases, based on the basic e.m.f.

equation, the flux required decreases. Thus, the transformer size is reduced.

(6) Welding. Welding

is the process of fusing metal pieces together by passing short-lived and

high-value currents through the area of contact. The power required for welding

is

P=I2R.P=I2R.

Current

is increased with the help of a step-down transformer. This welding power is

controlled by an AC chopper. Integral number of cycles can be

applied by firing the thyristors for a

particular time interval and subsequently turning it off for a particular time.

(7) Heaters. There

are two types of heating that are done with the help of the power

electronics equipments. They are resistance

heating and induction heating.

Resistance heating is done

with the help of a metallic conductor, non-metallic conductor e.g. carbon

tubes, liquids and the power electronics equipment i.e. AC chopper. Heating

resistor is made up of alloys such as nickel, chromium and etc. Its principle

is similar to welding i.e. integral cycle control of AC chopper. This type of

heating is used to heat insulated furnaces for production or laboratory

purposes.

Induction heating is used in

several applications such as melting, forging, brazing, soldering, annealing,

forging, surface hardening and etc. It is also known as the eddy current heating

as the heat generated in it is due to the eddy current. When an alternating

voltage is applied to the job coil, an alternating current will flow. This

current induces an alternating magnetic field. The metallic job in this field

cuts the alternating magnetic flux and an emf is

induced in it. This induced emf causes the

circulation of the eddy current and heat is produced. If the supply

frequency is increased with the help of semiconductor devices such as cycloconverter, the eddy current will also increase and

more heat is produced.

The induction heating is also

currently used for electronic heaters employing a rectifier, filter and an

inverter in sequence. When an alternating field is applied to the

non-conducting material, heat is generated. This heat generated is due to the

dielectric loss and this process is called as the dielectric heating. The

amount of heat depends on the dielectric strength of the job. This dielectric

heating method is used in plastic, wood, textile, rubber, food and chemical industries

and etc.

(8) Static on load

tap changing gear. To reduce the voltage variation obtained from the

load variation, a tap changing gear transformer is required. Changing the tap

setting actually means changing the turn ratio of the transformer in order to

vary the voltage. It requires the making and braking of the electrical

contacts, which is usually done manually. However, there may be loads where

load disconnection is not acceptable, where an on-load tap changer is required

for such purpose. The making and braking of electrical contacts may cause

sparking and pitting or erosion of electrical contacts. Also, it may

contaminate the oil of the transformer. Moreover, on-load tap changers have

high-cost, high-maintenance requirements, slow responses, and voltage

fluctuation problems. These problems can be overcome with the aid of

a voltage controller that has two anti-parallel controlled switches. It reduces

the transient voltage dips and continuous control of voltage is obtained.

(9) Static VAR

compensators. These are power electronics devices which supply and

compensate the lagging reactive power consumed by the inductive

loads. They help in maintaining the constant supply voltage with power factor

improvement. There are various power electronics equipments such

as thyristor-switched capacitors (TSC), thyristor-controlled reactors (TCR), STATCOM, UPSC, UPFC

and etc.

(10) Uninterrupted power

supply (UPS): A simple UPS consists of a rectifier, an inverter, and a battery.

The battery provides the supply to the inverter whenever there is no supply

power from the conventional source. However, if any UPS component fails, it

stops working. It is actually not very reliable. A more reliable system can be

obtained by using more components in parallel. In the case of parallel

configuration, if there is any fault in any of the inverters, that part can be

isolated with the help of solid-state interrupter. UPS must also minimize

voltage transients on the bus and supply the power to the critical load during

the long power outage.

(11) HVDC

transmission. Generation of high-voltage DC is limited due to the

conditions/limitations of DC generators. Thus, it is converted into DC at the

sending end and then transmitted. At the receiving end, it is converted back

into an AC with the help of an inverter. Monopolar and bipolar schemes are

employed for the HVDC. Since the series reactance in the case of HVDC system is

nil, there is no stability problem. Hence, higher operating voltage of HVDC is

possible.

(12) Static switches. These

are switches that have no moving parts. Thyristors are

used as static switches for high-power applications while power transistors are

used for low-power applications. Static switches have very high switching speed

and long operational life. Since they have no moving components, maintenance is

almost not required.

Static switches have two

types depending upon the supply i.e. AC static switch and DC static switch.

These switches act as relays for AC and DC circuits. If the input is AC, then

AC static switches are used; and when the input is DC, the DC static switches

are used. The switching speed of AC switches depends upon the supply frequency

while the switching speed of DC switches depends upon the commutation circuitry

used.

(13) Static Circuit

Breakers. These are semiconductor devices which provide a rapid and reliable

interruption of a continuous current. There are two types of static circuit

breakers, the AC and the DC circuit breaker.