The How and Why of Energy Harvesting for Low-Power Applications

In this article, we'll go over the basics of

energy harvesting and discuss what forms it can take when scavenging energy

from different sources.

What Is

Energy Harvesting

Energy harvesting is the capture and conversion

of small amounts of readily available energy in the environment into usable

electrical energy. The electrical energy is conditioned for either direct use

or accumulated and stored for later use. This provides an alternative source of

power for applications in locations where there is no grid power and it is

inefficient to install wind turbines or solar panels.

Other than outdoor solar, no small energy

sources provide a great deal of energy. However, the energy captured is

adequate for most wireless applications, remote sensing, body implants, RFID,

and other applications at the lower segments of the power spectrum. And even if

the harvested energy is low and incapable of powering a device, it can still be

used to extend the life of a battery.

Energy harvesting is also known as energy

scavenging or micro energy harvesting.

Why Harvest

Energy

Most low-power electronics, such as remote

sensors and embedded devices, are powered by batteries. However, even

long-lasting batteries have a limited lifespan and must be replaced every few

years. The replacements become costly when there are hundreds of sensors in

remote locations. Energy harvesting technologies, on the other hand, provide

unlimited operating life of low-power equipment and eliminate

the need to replace batteries where it is costly, impractical, or dangerous.

Most energy harvesting applications are

designed to be self-sustaining, cost-effective, and to require little or no

servicing for many years. In addition, the power is used closest to the source,

hence eliminating transmission losses and long cables. If the energy is enough

to power the device directly, the application or device powered by the energy

can operate batteryless.

The Building

Blocks of an Energy Harvesting System

The process of energy harvesting takes

different forms based on the source, amount, and type of energy being converted

to electrical energy. In its simplest form, the energy harvesting system

requires a source of energy such as heat, light, or vibration, and the

following three key components.

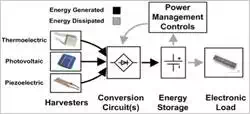

Figure (1) Basic components of an energy harvesting system. Image

courtesy of harvesting-energy.com.

● Transducer/harvester: This

is the energy harvester that collects and converts the energy from the source

into electrical energy. Typical transducers include photovoltaic for light,

thermoelectric for heat, inductive for magnetic, RF for radio frequency, and

piezoelectric for vibrations/kinetic energy.

● Energy

storage: Such as a battery or super capacitor.

● Power

management: This conditions the electrical energy into a suitable form for the

application. Typical conditioners include regulators and complex control

circuits that can manage the power, based on power needs and the available

power.

Common

Sources of Energy

● Light

energy: From sunlight or artificial light.

● Kinetic

energy: From vibration, mechanical stress or strain.

● Thermal

energy: Waste energy from heaters, friction, engines, furnaces, etc.

● RF energy:

From RF signals.

Energy

Harvesting Technologies

Harvesting electrical power from

non-traditional power sources using thermoelectric generators, piezoelectric

transducers, and solar cells still remains a challenge. Each of these requires

a form of power conversion circuit to efficiently collect, manage, and convert

the energy from these sources into usable electrical energy for

microcontrollers, sensors, wireless devices, and other low-power circuits.

Harvesting Kinetic Energy

Piezoelectric transducers produce electricity

when subjected to kinetic energy from vibrations, movements, and sounds such as

those from heat waves or motor bearing noise from aircraft wings and other

sources. The transducer converts the kinetic energy from vibrations into an AC

output voltage which is then rectified, regulated, and stored in a thin film

battery or a super capacitor.

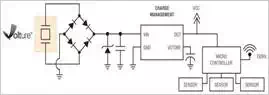

Figure

(2) Midé Volture Piezoelectric Energy Harvesting Circuit. Image

courtesy of Mouser.

Potential sources of kinetic energy include

motion generated by humans, acoustic noise, and low-frequency vibrations. Some

practical examples are:

● A batteryless remote control unit: Power is harvested

from the force that one uses in pressing the button. The harvested energy is

enough to power the low-power circuit and transmit the infrared or wireless

radio signal.

● Pressure

sensors for car tires: Piezoelectric energy harvesting sensors are put inside

the car tire where they monitor pressure and transmit the information to the

dashboard for the driver to see.

● Piezoelectric

floor tiles: Kinetic energy from people walking on the floor is converted to

electrical power that can be used for essential services such as display

systems, emergency lighting, powering ticket gates, and more.

Harvesting RF Energy

In this arrangement, an RF power receiving

antenna collects the RF energy signal and feeds it to an RF transducer such as

the Powercasts P2110 RF Powerharvester.

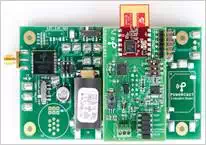

A P2110 Powerharvester receiver

evaluation board. Image courtesy of Nuts and Volts (PDF).

The Powerharvester converts

the low-frequency RF signal to a DC voltage of 5.25V, capable of delivering up

to 50mA current. It is possible to make a completely battery-free wireless

sensor node by combining sensors, the P2110, a radio module, and a low-power

MCU.

Typical applications for these types of sensors

include building automation, smart grid, defense,

industrial monitoring, and more.

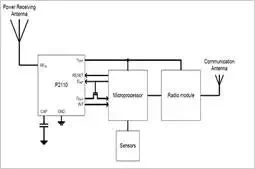

Figure (3) Powercast P2110 RF energy

harvesting for a batteryless wireless

sensor. Image courtesy of Powercast.

Harvesting Solar Energy

Small solar cells are used in industrial and

consumer applications such as satellites, portable power supplies, street

lights, toys, calculators, and more. These utilize a small photovoltaic cell

which converts light to electrical energy. For indoor applications, light is

usually not very strong and typical intensity is about 10 µW/cm².

The power from an indoor energy harvesting

system thus depends on the size of the solar module as well as the intensity or

spectral composition of the light. Due to the intermittent nature of light,

power from solar cells is usually used to charge a battery or supercapacitor to

ensure a stable supply to the application.

Harvesting Thermal Energy

Thermoelectric energy harvesters rely on

the Seebeck effect in

which voltage is produced by the temperature difference at the junction of two

dissimilar conductors or semiconductors. The energy harvesting system consists

of a thermoelectric generator (TEG) made up of an array of thermocouples that

are connected in series to a common source of heat. Typical sources include

water heaters, an engine, the back of a solar panel, the space between a power

component such as a transistor and its heat sink, etc. The amount of energy

depends on the temperature difference, as well as the physical size of the TEG.

The TEGs are useful in recycling energy that

would otherwise have been lost as heat. Typical applications include powering

wireless sensor nodes in industrial heating systems and other high-temperature

environments.

Harvesting Energy from Multiple Sources

Manufacturers such as Maxim, Texas Instruments,

and Ambient Micro have developed some integrated circuits with the ability to

simultaneously capture different types of energy from multiple sources.

Combining multiple sources has the benefit of maximizing the peak energy as

well as providing energy even when some sources are unavailable.

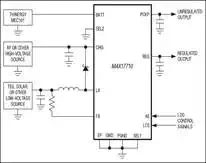

An example of a circuit that harvests energy

from multiple sources is as shown below:

Figure (4) Maxim Integrated MAX17710 multiple source circuit . Image courtesy of Maxim Integrated.

Benefits of

Energy Harvesting

There is plenty of energy in the environment

which can be converted into electrical energy to power a variety of circuits.

Energy harvesting is beneficial because it

provides a means of powering electronics where there are no conventional power

sources, eliminating the need for frequent battery replacements and running

wires to end applications. By this same token, it opens up new applications in

remote locations, underwater, and other difficult-to-access locations where

batteries and conventional power are not realistic.

Energy harvesting is also largely maintenance

free and is environmentally friendly.

Applications

for Energy Harvesting Technologies

Alternative power sources provide a means of

extending the battery life of remote sensors in industrial, commercial, and

medical applications. This enables installation of standalone sensors in

hard-to-reach or remote areas to provide a variety of information and warnings.

These sensors can monitor and warn of air pollution, worn out bearings, bridge

stresses, forest fires, and more.

Other applications include:

● Remote

corrosion monitoring systems

● Implantable

devices and remote patient monitoring

● Structural

monitoring

● RFID

● Internet

of Things (IoT)

● Equipment

monitoring

Desirable

Properties of Energy Harvesting Applications

Since the energy from harvested sources is

intermittent and small, the systems must be carefully designed to efficiently

capture, condition, and store the power. The systems should further incorporate

circuits to control the charging process and regulate the power for the

sensors, MCUs, and other low-power loads.

Harvesting

Circuit

Energy management system components should have:

● High

energy efficiency in capturing, accumulating, and storing small energy packets.

Efficiency must be high enough to ensure that the energy consumed by the energy

harvesting circuit is much smaller than the energy captured from the source.

● High energy

retention with minimal leakage or losses in energy storage.

● Energy

conditioning to ensure the output meets power requirements for the application

or desired task.

● Tolerance

of a wide range of voltages, currents, and other irregular input conditions.

Application

Circuit

Circuits receiving harvested energy for

application should:

● Consume

the lowest amount of electrical power possible when active.

● Consume

the lowest standby current.

● Be capable

of turning on and off with minimal delay.

● Operate at

the low-voltage range.

Conclusion

Harvesting energy from nonconventional sources

in the environment has received increased interest over the past few years as

designers look for alternative energy sources for low-power applications.

Even though energy harvested is small and in

the order of milliwatts, it can provide enough

power for wireless sensors, embedded systems, and other low-power applications.