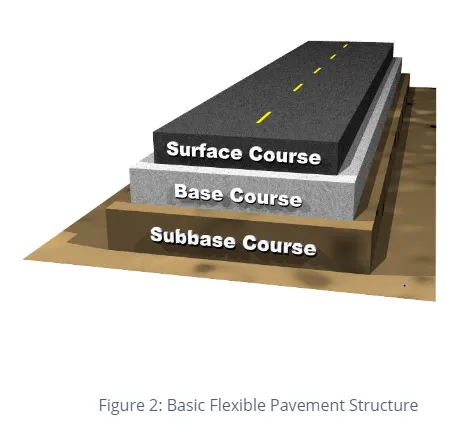

Pavement Structure

HMA pavements are flexible pavements. Flexible pavements are

so named because the total pavement structure deflects, or flexes, under

loading. A flexible pavement structure

is typically composed of several layers of material each of which receives the

loads from the above layer, spreads them out, then passes

them on to the layer below. Thus, the further down in the pavement structure a

particular layer is, the less load (in terms

of force per area) it must carry.

Basic Structural Elements

Material layers are usually arranged within a

pavement structure in order of descending load bearing capacity with the

highest load bearing capacity material (and most expensive) on the top and the

lowest load bearing capacity material (and least expensive) on the bottom. A

typical flexible pavement structure (see Figure 2) consists of:

- Surface Course. The layer in

contact with traffic loads. It provides characteristics such as friction,

smoothness, noise control, rut resistance and drainage. In addition, it

prevents entrance of surface water into the underlying base, subbase and subgrade (NAPA, 2001[1]).

This top structural layer of material is sometimes subdivided into two

layers: the wearing course (top) and

binder course (bottom). Surface courses are most often constructed out of

HMA.

- Base Course. The layer

immediately beneath the surface course. It provides

additional load distribution and contributes to drainage. Base courses are usually

constructed out of crushed aggregate or HMA.

- Subbase Course. The layer between

the base course and

subgrade. It functions primarily as structural support but it can also

minimize the intrusion of fines from the subgrade into the pavement

structure and improve drainage. The subbase generally

consists of lower qualitymaterials than

the base course but better

than the subgrade soils. A subbase course

is not always needed or used. Subbase courses

are generally constructed out of crushed aggregate or engineered fill.

Surface Course:

The surface course is the layer in contact with

traffic loads and normally contains the highest quality materials. It provides

characteristics such as friction, smoothness, noise control, rut and shoving resistance and

drainage. In addition, it serves to prevent the entrance of excessive

quantities of surface water into the underlying base, subbase and

subgrade (NAPA, 2001[1]). This

top structural layer of material is sometimes subdivided into two layers:

- Wearing

Course.

This is the layer in direct contact with traffic loads. It is meant to

take the brunt of traffic wear and can be removed and replaced as it

becomes worn. A properly designed (and funded) preservation program should

be able to identify pavement surfacedistress while it is still confined to the wearing course. This way, the

wearing course can be rehabilitated before distress propagates into the

underlying intermediate/binder course.

- Intermediate/Binder Course. This layer provides the bulk of the

HMA structure. Its chief purpose is to distribute load.

Base Course:

The base course is immediately

beneath the surface course. It provides additional load distribution and

contributes to drainage and frost resistance. Base courses are usually

constructed out of:

- Aggregate. Base courses are most typically

constructed from durable aggregates (see Figure 4) that will not be

damaged by moisture or frost action. Aggregates can be either stabilized

or unstabilized.

- HMA. In certain situations where high

base stiffness is desired, base courses can be constructed using a variety

of HMA mixes. In relation to surface course HMA mixes, base course mixes

usually contain larger maximum aggregate sizes, are

more open graded and are subject to more lenient specifications.

Figure 4. Limerock base course undergoing final grading.

Subbase Course:

The subbase course

is between the base course and the subgrade. It functions primarily as

structural support but it can also:

- Minimize

the intrusion of fines from the subgrade into the pavement structure.

- Improve

drainage.

- Minimize frost

action damage.

- Provide

a working platform for construction.

The subbase generally consists of lower quality materials than the base course but better than the subgrade soils. A subbase course is not always needed or used. For example, a pavement constructed over a high quality, stiff subgrade may not need the additional features offered by a subbase course so it may be omitted from design. However, a pavement constructed over a low quality soil such as a swelling clay may require the additional load distribution characteristic that a subbase course can offer. In this scenario the subbase course may consist of high quality fill used to replace poor quality subgrade.

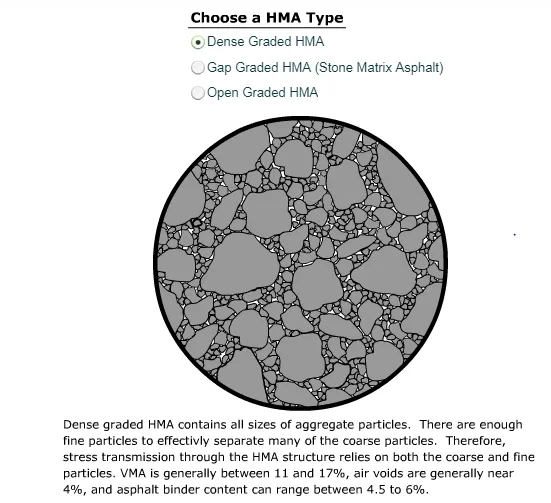

Figure 5. HMA mix types.

Types

There are many different types of HMA pavements.

This section covers three of the more common types of HMA mix types used in the

U.S. Other flexible pavements such as bituminous surface treatments

(BSTs) are considered by most agencies to be a form of maintenance.

HMA mix types differ from each other mainly in maximum aggregate size, aggregate gradation and asphalt binder content/type. Pavement

Interactive focuses on dense-graded HMA because it is the most

common HMA pavement material in the U.S. The three most common types of HMA

pavement are:

- Dense-graded

HMA. Flexible pavement information

in this Guide is generally concerned with dense-graded HMA. Dense-graded

HMA is a versatile, all-around mix making it the most common and

well-understood mix type in the U.S.

- Stone

matrix asphalt (SMA). SMA, although relatively new in the U.S., has been

used in Europe as a material for years to support heavy traffic loads and

resist studded tire wear.

- Open-graded HMA. This includes both open-graded friction course (OGFC) and asphalt treated permeable materials. Open-graded mixes are typically used as wearing courses (OGFC) or underlying drainage layers because of the special advantages offered by their porosity.