Hydraulic Accumulators Theory and Use

Energy can neither be created nor be destroyed. But it can be transformed from one from to another. This energy can also be stored in a device or equipment, so that it can be used in the other form. Have you ever wondered how hydraulic energy is stored? Here's how.

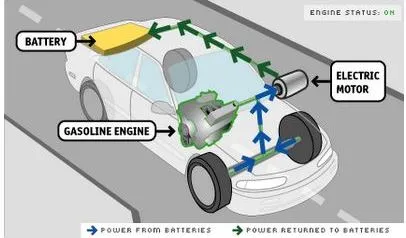

“Energy can neither be created nor be destroyed, but it can be transformed from one from to another." This energy can also be stored in a device or equipment, so that they can be used in another form. For example, we know about the function of flywheel in a rotary machine. It gains energy from the prime mover, stores the gained energy, and, when required, releases the energy back into the same system. Another example of energy storage and conversion, which is the most recent development in the automobile industry, is the K.E.R.S, or Kinetic Energy Recovery System. The system utilizes the kinetic energy when the car reduces its speed, and gives it back to the car itself for its acceleration. Thus energy is stored in some form and given back to the system in another form. The point I try to emphasize here is “energy is stored." Have you ever wondered how energy is stored? Read here to know about one of the most widely used energy storage devices, the hydraulic accumulator.

What is a Hydraulic Accumulator?

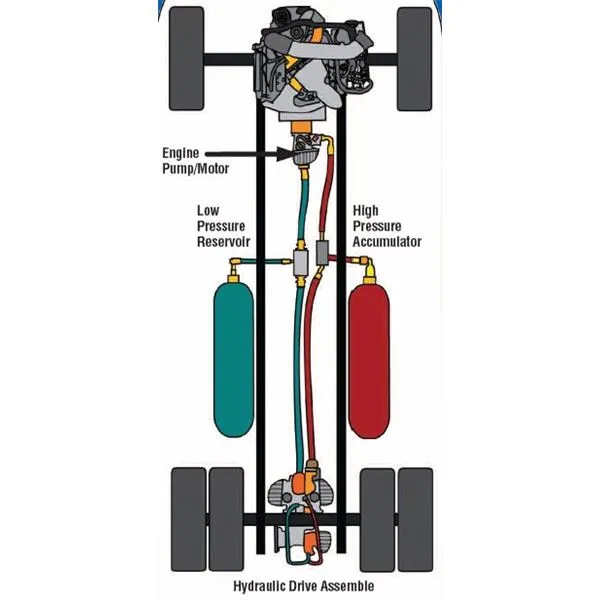

It is a simple hydraulic device which stores energy in the form of fluid pressure. This stored pressure may be suddenly or intermittently released as per the requirement. In the case of a hydraulic lift or hydraulic crane, a large amount of energy is required when the lift or crane is moving upward. This energy is supplied from the hydraulic accumulator. But when the lift is moving in the downward direction, it does not require a huge amount of energy. During this particular time, the oil or hydraulic fluid pumped from the pump is stored in the accumulator for future use.

Working of Hydraulic Accumulator:

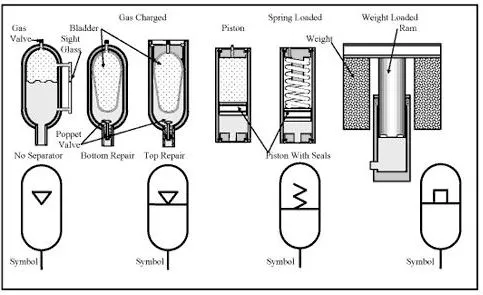

An accumulator usually has a cylindrical chamber, which has a piston in it. This piston is either spring loaded or some calculated weight is kept on it or even pneumatically pressurized. The hydraulic pump pumps the fluid into the accumulator, which is nothing but a sealed container. The volume of the container is fixed and cannot be changed. But the quantity of hydraulic fluid being pumped inside the container is increasing continuously. So the pressure of the hydraulic fluid inside the container starts to increase.

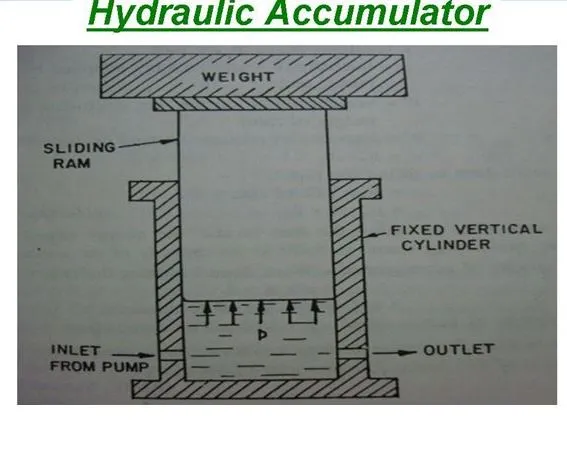

The figure to the left shows a hydraulic accumulator which consists of a fixed vertical cylinder containing a sliding ram. A heavy weight is placed on the ram. The inlet of the cylinder is connected to the pump, which continuously supplies water or the hydraulic fluid under pressure to the cylinder. The outlet of the cylinder is connected to the machine (which may be a lift or a crane).

The ram is at its lower most position in the beginning. The pump supplies hydraulic fluid under pressure continuously. If the hydraulic fluid under pressure is not required by the machine, it will be stored in the cylinder. This will raise the ram on which a heavy weight is placed. When the ram is at its upper most position, the cylinder is full of hydraulic fluid and the accumulator has stored the maximum amount of pressure energy. When the machine (the crane or the lift), requires a large amount of energy, the accumulator will supply this energy and the ram starts to move down.

But is there any pressure limitation?

As mentioned earlier, there is a weight kept upon the ram or the ram is held against spring pressure or sometimes even air pressure. So it is this force of the spring, weight, or the air pressure which decides the pressure of fluid stored inside the container. The pump pressurizes the fluid inside the container until the weight is lifted completely or the spring is compressed totally, after which the pump stops automatically (or sometimes manually).

What is the use of this stored pressure energy?

The hydraulic fluid stored inside the container has energy in the form of pressure. This pressure energy can be used for many operations. For example, in industries an infinite numbers of valves are provided in the pipelines and it is not possible for the operator to operate every valve manually and sometimes it is not possible to remember the location of all the valves. A mimic diagram is located in the control room, thus making it possible to have a bird’s eye view of all the valves. These valves are usually operated hydraulically in a remote manner. The system generally has an oil reservoir, a pump, an accumulator, pipelines, and valves. The pump pressurizes the hydraulic oil through the accumulator and pipelines, thus operating the corresponding valves. When the operations are completed, the pump pressurizes the oil into the accumulator which stores the oil under pressure for further use.

Why do we need an Accumulator?

If there were no accumulator, the hydraulic pump would be continuously running to cater to the need for valve operation. The pump will frequently start and stop, which affects the pump’s performance and its health. Also, the accumulator stores energy which can be used in an emergency where there is no other means of power supply. It can be compared with the use of capacitors in electrical circuits. In hotels and other industries, water is usually stored in accumulators called “hydrophores" that are capable of supplying water to higher heights reducing the burden on the pumps - for example, if there are plants where the water tanks cannot be placed on top of the building due to some constraints and are thus placed on the ground. To supply water to a greater height, it requires comparatively a higher capacity pump. But it can be replaced with a lower capacity pump and a hydrophore, which is an accumulator. Water is stored against air pressure inside the accumulator and whenever the need for water arises at a greater height, water is pumped with the help of air pressure inside the accumulator, just by opening some corresponding valves. This reduces the requirement of a higher capacity pump and avoids a continuous start-stop cycle of the pumps.

To supplement pump flow: As discussed earlier, the most common use for accumulators is to supplement pump flow. Certain machinery circuits require a high quantity of oil flow for a short time and then use little or no fluid for an extended period. So, generally when the circuit does not require oil flow, the pump keeps the accumulator pressurized for future use.

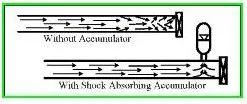

To absorb shock: At times, the sudden changing of valve positions or operations may cause a pressure wave which sets up a shock. The pressure of fast-moving hydraulic circuits can produce pressure spikes that cause shock when flow is stopped abruptly as well. When installed in shock prone areas of hydraulic circuits, accumulators serve as pressure shock dampening devices.

As an emergency power supply: Ships generally have emergency means of starting arrangements for life saving appliances. The life boat engines are either manually started or sometimes hydraulically started. These act as secondary means of starting in times of emergency.