Concrete That Compacts on Its Own? - Description and Advantages

This type of concrete, unlike the conventional one, can be conveniently poured in narrow places since it does not require vibration. The ingredients are the same as in the conventional mixture except for the water reducing agent that improves its properties. Read the article to find out more!

Enhanced Properties and Characteristics

Self-compacting concrete is a modern and innovative concrete that does not need vibration for placement and compaction. It is also known as flowable, self-consolidating, and non-vibration concrete. It is enormously consistent and highly flowable, without the loss of stability, and moreover it can flow due to its weight, fill the formwork and achieve complete compaction even in the presence of crowded reinforcement. After solidification, it is hard, consistent, and has similar engineering characteristics, including strength, as conventional concrete that has been vibrated. Therefore after hardening, its function is like normal (vibrated) concrete.

Concrete that needs little compaction or vibration was developed in the early 1970s. However, the non-vibration concrete was developed in Japan during the 1980s. It currently makes up almost 5% of the market in Japan, around 15% in the Danish and Swedish markets and its use is very popular in the UK as well.

Composition of the Concrete Mixture

Several ingredients are used during the production. Normally, a water reducing agent is added to the traditional concrete mix, maintaining the same ratio of water and cement. This mixture produces a concrete with good characteristics of flow, and generally a high compressive strength. This product discourages segregation by the elimination of electrostatic magnetism between the negative and positive charges. An electrostatic repelling action is stimulated that increases the negative charge in the concrete particles and produces the desired characteristics.

Fly ash is often used, mainly due to its water-reducing abilities, and it can have a significant bearing on the final concrete produced. Fine fillers, such as ground limestone, may also be used.

Strengths can reach 30-40N/mm2 within a few hours and they can even break the 100N/mm2 barrier after a few days.

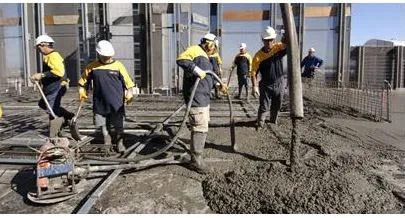

Self-consolidating concrete has a fast rate of concrete placement, with a swift flow close to the congested reinforcement region. This enables the achievement of rapid construction. The resistance to segregation and high fluidity ensures homogeneity, minimum voids, and a consistent concrete strength. These characteristics provide excellent durability and finish to the building. The mixture is produced with a low ratio of water and cement that makes the concrete have a high strength. Furthermore, the exclusion of vibrating machinery assists in a clean environment near the construction site. The workers also do not have to bear the uncomfortable noise created due to vibration.

Why Use This Type of Concrete?

Some areas where concrete is poured have spaces that are congested with reinforced bars, and placing normal concrete in such locations is difficult. Self-compacting concrete can conveniently be used for complex shapes, narrow shells, and where conventional vibration may not be possible. Use of normal concrete at such places can cause voids that are undesirable. Self-compacting concrete is especially useful for structures that require a high quality, with no deviation in color, texture, and smoothness. However, the use of this type of concrete is limited due to its high cost.