CASE STUDY – WORLD TRADE CENTER COLLAPSE.

The collapse of the World Trade Center (WTC) towers on September 11, 2001, was as sudden as it was dramatic; the complete destruction of such massive buildings shocked nearly everyone. Immediately afterward and even today, there is widespread speculation that the buildings were structurally deficient, that the steel columns melted, or that the fire suppression equipment failed to operate. In order to separate the fact from the fiction, I have attempted to quantify various details of the collapse.

The major events include the following:

The airplane impact with damage to the columns.

The ensuing fire with loss of steel strength and distortion (figure 6.3)

The collapse, which generally occurred inward without significant tipping. (figure6.4)

Before going to the details it is useful to review the overall design of the towers.

6.1 THE DESIGN

The towers were designed and built in the mid-1960s through the early 1970s each tower was 64 m square, standing 411 m above street level and 21 m below grade. This produces a height-to-width ratio of 6.8. The total weight of the structure was roughly 500,000 t. The building is a huge sail that must resist a 225 km/h hurricane. It was designed to resist a wind load of 2 KPa—a total of lateral load of 5,000 t.

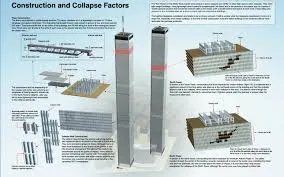

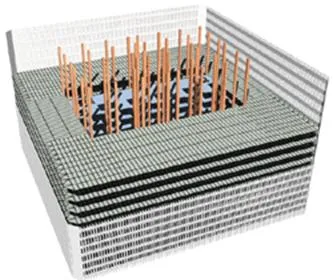

In order to make each tower capable of withstanding this wind load, the architects selected a lightweight “perimeter tube” design consisting of 244 exterior columns of 36 cm square steel box section on 100 cm centers(figure 3). This permitted windows more than one-half meter wide. Inside this outer tube there was a 27 m × 40 m core, which was designed to support

Figure 6.1 a cutaway view of WTC structure.

The weight of the tower It also housed the elevators, the stairwells, and the mechanical risers and utilities. Web joists 80 cm tall connected the core to the perimeter at each story. Concrete slabs were poured over these joists to form the floors. In essence, the building is an egg-crate construction, i.e. 95 percent air.

The egg-crate construction made a redundant structure (i.e., if one or two columns were lost, the loads would shift into adjacent columns and the building would remain standing). The WTC was primarily a lightweight steel structure; however, its 244 perimeter columns made it “one of the most redundant and one of the most resilient” skyscrapers.

DETAILS OF THE COLLAPSE

THE AIRPLANE IMPACT

The early news reports noted how well the towers withstood the initial impact of the aircraft; however, when one recognizes that the buildings had more than 1,000 times the mass of the aircraft and had been designed to resist steady wind loads of 30 times the weight of the aircraft, this ability to withstand the initial impact is hardly surprising. Furthermore, since there was no significant wind on September 11, the outer perimeter columns were only stressed before the impact to around 1/3 of their 200 MPa design allowable.

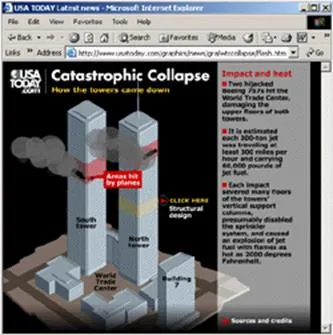

Figure 6.2 A graphic illustration, from the USA Today newspaper web site, of the World Trade Center points of impact.

The only individual metal component of the aircraft that is comparable in strength to the box perimeter columns of the WTC is the keel beam at the bottom of the aircraft fuselage. While the aircraft impact undoubtedly destroyed several columns in the WTC perimeter wall, the number of columns lost on the initial impact was not large and the loads were shifted to remaining columns in this highly redundant structure. Of equal or even greater significance during this initial impact was the explosion when 90,000 L gallons of jet fuel, comprising nearly 1/3 of the aircraft’s weight, ignited. The ensuing fire was clearly the principal cause of the collapse (see figure 6.2)

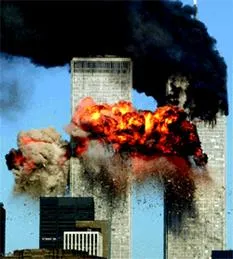

Figure 6.3 Flames and debris exploded from the World Trade Center south tower immediately after the airplane’s impact. The black smoke indicates a fuel-rich fire

The fire is the most misunderstood part of the WTC collapse. Even today, the media report (and many scientists believe) that the steel melted. It is argued that the jet fuel burns very hot, especially with so much fuel present. This is not true.

Part of the problem is that people often confuse temperature and heat. While they are related, they are not the same. Thermodynamically, the heat contained in a material is related to the temperature through the heat capacity and the mass. Temperature is defined as an intensive property, meaning that it does not vary with the quantity of material, while the heat is an extensive property, which does vary with the amount of material. One way to distinguish the two is to note that if a second log is added to the fireplace, the temperature does not double; it stays roughly the same, but the length of time the fire burns, doubles and the heat so produced is doubled. Thus, the fact that there were 90,000 L of jet fuel on a few floors of the WTC does not mean that this was an unusually hot fire. The temperature of the fire at the WTC was not unusual, and it was most definitely not capable of melting steel.

In combustion science, there are three basic types of flames, namely, a jet burner, a pre-mixed flame, and a diffuse flame. A jet burner generally involves mixing the fuel and the oxidant in nearly stoichiometric proportions and igniting the mixture in a constant-volume chamber. Since the combustion products cannot expand in the constant-volume chamber, they exit the chamber as a very high velocity, fully combusted, jet. This is what occurs in a jet engine, and this is the flame type that generates the most intense heat.

In a pre-mixed flame, the same nearly stoichiometric mixture is ignited as it exits a nozzle, under constant pressure conditions. It does not attain the flame velocities of a jet burner. An oxyacetylene torch or a Bunsen burner is a pre-mixed flame.

In a diffuse flame, the fuel and the oxidant are not mixed before ignition, but flow together in an uncontrolled manner and combust when the fuel/oxidant ratios reach values within the flammable range. A fireplace flame is a diffuse flame burning in air, as was the WTC fire. Diffuse flames generate the lowest heat intensities of the three flame types.

If the fuel and the oxidant start at ambient temperature, a maximum flame temperature can be defined. For carbon burning in pure oxygen, the maximum is 3,200°C; for hydrogen it is 2,750°C. Thus, for virtually any hydrocarbons, the maximum flame temperature, starting at ambient temperature and using pure oxygen, is approximately 3,000°C.

This maximum flame temperature is reduced by two-thirds if air is used rather than pure oxygen. The reason is that every molecule of oxygen releases the heat of formation of a molecule of carbon monoxide and a molecule of water. If pure oxygen is used, this heat only needs

To heat two molecules (carbon monoxide and water), while with air, these two molecules must be heated plus four molecules of nitrogen. Thus, burning hydrocarbons in air produces only one-third the temperature increase as burning in pure oxygen because three times as many molecules must be heated when air is used. The maximum flame temperature increase for burning hydrocarbons (jet fuel) in air is, thus, about 1,000°C—hardly sufficient to melt steel at 1,500°C.

THE COLLAPSE

Figure 6.4 as the heat of the fire intensified, the joints on the most severely burned floors gave way, causing the perimeter wall columns to bow outward and the floors above them to fall. The buildings collapsed within ten seconds, hitting bottom with an estimated speed of 200 km/hr.

Nearly every large building has a redundant design that allows for loss of one primary structural member, such as a column. However, when multiple members fail, the shifting loads eventually overstress the adjacent members and the collapse occurs like a row of dominoes falling down.

The perimeter tube design of the WTC was highly redundant. It survived the loss of several exterior columns due to aircraft impact, but the ensuing fire led to other steel failures. Many structural engineers believe that the weak points—were the angle clips that held the floor joists between the columns on the perimeter wall and the core structure .With a 700 Pa floor design allowable, each floor should have been able to support approximately 1,300 t beyond its own weight. The total weight of each tower was about 500,000 t.

As the joists on one or two of the most heavily burned floors gave way and the outer box columns began to bow outward, the floors above them also fell. The floor below (with its 1,300 t design capacity) could not support the roughly 45,000 t of ten floors (or more) above crashing down on these angle clips. This started the domino effect that caused the buildings to collapse within ten seconds, hitting bottom with an estimated speed of 200 km per hour. If it had been free fall, with no restraint, the collapse would have only taken eight seconds and would have impacted at 300 km/h.

Can buildings resist direct airplane hits?

If the “design” terrorist attack is similar to that of Sept. 11, can buildings be given the capacity to meet this demand? To answer this question, it is important to understand the physics at work when a plane in flight is stopped by a building.

If the performance objective is to “resist” a direct airplane hit and protect people inside the building, the plane cannot be allowed to penetrate the exterior wall. To stop a Boeing 767 traveling in excess of 500 miles per hour in a distance of a few feet would take a deceleration force in excess of 400 million pounds.

Each tower of the World Trade Center was designed for a total horizontal force (or “design wind load”) of about 15 million pounds. The total design wind load for a more commonly sized high-rise, say, 40 stories tall, would be about 4 million pounds. In other words, to resist the amount of force generated by a direct 767 hit, today’s buildings would need to be 100 times stronger than dictated by code, which is both physically and economically impossible.

So why did the World Trade Center Towers not collapse immediately due to the impact load on the system? The planes did not stop in a few feet, but had an effective stopping distance of over 100 feet. This would drop the deceleration force down to something close to the capacity of the building.

Another part of the answer to this question lies in the way that the exterior of the building was structured. The exterior columns were 14-inch square welded steel box columns spaced at 40 inches on center. This means that there was only 26 inches clear between each column. The columns were integral with the steel spandrels beams and formed essentially a solid wall of steel with perforations for windows. This wall construction was able to form a Vierendeel “bridge” over the hole created in one side of each of the towers.

Both of these facts — that the plane was not stopped at the exterior and that the columns and spandrels were extremely dense — were necessary to prevent the building from collapsing immediately upon impact.

Can buildings be designed for direct airplane hits? Yes and no. Yes, for small aircraft. A definite no, for large commercial aircraft.

How can we minimize the chance of progressive collapse?

This is still one more question that some people are asking. Because the towers ultimately collapsed with one floor crashing down upon the next, it has been called a progressive collapse.

Again, it is important to think carefully about the question. Aren’t all collapses progressive? Something breaks, and then something else breaks, and so on. Normally, when the term progressive collapse is used, it specifically refers to the loss of one or two columns or bearing walls that cause a collapse to propagate vertically.

In the case of the World Trade Center there were about 40 columns lost on one face of each of the towers and there was no propagation of collapse from this loss. So did the World Trade Center have good resistance to progressive collapse? By normal use of the term “progressive collapse” it did. The collapse that did ultimately occur was progressive, like all collapses, but was not “progressive collapse” that some international codes address.

The difficulty in understanding this concept is illustrated with the following story.

A New York fire chief wrote that experienced firefighters know that the buildings that are most susceptible to progressive collapse are buildings that are well-tied together (i.e., able to transfer building loads from one element to another, such as a column). Yet, virtually every structural engineer will advise that one of the best ways to prevent progressive collapse is to tie the building together. How can there be this kind of a contradiction?

The difference is that the engineer is thinking about losing a column or two and the fire chief is talking about losing a whole part of a building. As the event that initiates the progressive collapse becomes larger than losing a column, the risk becomes that the strong horizontal ties of a building will cause the collapse to propagate horizontally.

Any discussion of code provisions with respect to progressive collapse must recognize that both the engineer and the fire chief are right depending on the kind of hazard that is defined.

At least six safety systems present in the World Trade Center towers were completely and immediately disabled or destroyed upon impact: fireproofing, automatic sprinklers, compartmentalization and pressurization, lighting, structure and exit stairs.

Conclusions

There are structural techniques that can increase the capacity of building structures to resist certain kinds of terrorist attacks. However, there is absolutely no reliable way to design for the impact of a large scale commercial airliner.