Prevention of corrosion

Carbon dioxide and chloride present in the concrete are inert in the absence of the water and oxygen. Carbon dioxide in the pore of the concrete reacts with water to form carbonic acids which reduce the pH of the concrete. In the absence of water carbon dioxide is in active. Chloride in concrete is also in active at alkaline condition. In corrosion process carbon-dioxide acts as initiator and chloride acts as a catalyst. We can prevent corrosion by preventing the contact of water, carbon- dioxide and oxygen. Even in presence of water steel will not undergoes corrosion at alkaline environment.

Bio concrete

The bacteria and Ca(OH)2 of pH 13 is added to the concrete in a capsules. The bacteria are Bacillus alkali-nitrulicus, an alkali-resistant soil bacterium, psychrophilic bacterium, [8]Bacillus pasteurii is added, which can survey at high pH of 9 to 13 and at the temperature range of 10 to 40 degree centigrade. [5]Capsule of 15 kg is added to a 1m3 of concrete. The spores became active when getting contact with water, still it will be inactive in concrete. When bacteria contact with carbon-dioxide and convert calcium hydroxide to lime stone. On reaction CO2 is arrested from diffusion.

[9]Limestone will fill the crack and there is no possibility to leakage of water and diffusion of carbon-dioxide. Hear our primary aim is to prevent the carbon-dioxide penetration and then to prevent the water infiltration to concrete.

CO2 + Ca(OH)2 –> CaCO3 + H2O

In self-healing concrete capsule containing bacteria and calcium lactate is added. In atmosphere quantity of CO2 is less to speed up the self-healing process calcium lactate is added in which it precipitate CaCO3 and liberate CO2.

Ca(C3H5O2)2+7O2 –> CaCO3+5CO 2+5H2O

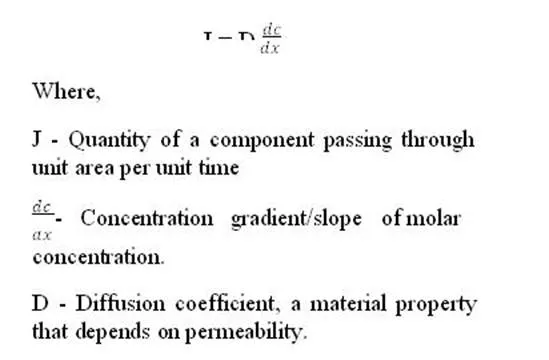

Diffusion of CO2

[7]Concrete will carbonate whenever carbon dioxide and some water are available. The speed of carbonation depends on how fast the carbon dioxide and/or the carbonate ions can move into the concrete and react with the cement paste. Diffusion is mass transport down a concentration gradient. Steady state diffusion follows Fick´s first law

Water cement ratio to reduce ‘D’

Water cement ratio in the concrete plays an important role in the strength and durability of the concrete. It has also been estimated that on an average 23% of water by weight of cement is required for chemical reaction with Portland cement compounds.

Fig.7 Phase diagram of concrete

This 23% of water chemically combines with cement and, therefore, it is called bound water. A certain quantity of water is imbibed within the gel- pores. This water is known as gel-water. It can be said that bound water and gel-water are complimentary to each other. If the quantity of water is inadequate to fill up the gel-pores, the formations of gel itself will stop and if the formation of gel stops there is no question of gel-pores being present. It has been further estimated that about 15 per cent by weight of cement is enof to fill up the gel-pores. [2] Therefore, a total 38 per cent of water by weight of cement is required for the complete chemical reactions and to occupy the space within gel-pores. If water equal to 38 per cent by weight of cement is only used it can be noticed that the resultant paste will undergo full hydration and no extra water will be available for the formation of undesirable capillary cavities. On the other hand, if more than 38 per cent of water is used, then the excess water will cause undesirable capillary cavities. Therefore greater the water above the minimum required is used (38 per cent), the more will be the undesirable capillary cavities. In all this it is assumed that hydration is taking place in a sealed container where moisture to and from the paste does not take place. Increases in cavity in a concrete increases the coefficient of diffusion in concrete. At a same time it is difficult to work in concrete at water cement ratio of 0.38.

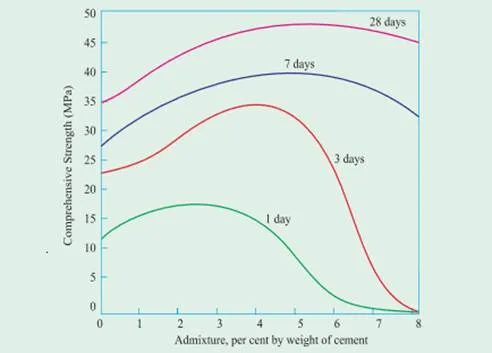

However addition of water to the concrete for a workability is not a good construction practices. Super plasticizer and new generation plasticizer is recommended for workability. Addition of plasticizer increases the strength up to optimum level above that it decreases the strength. [2]Fig.8 shows the variation of the compressive strength of the concrete at various volume of lingo-sulphonate. Hence optimum ratio of plasticizer is recommended. [2]Plasticizer reduce water content up to 10%, super plasticizer reduce about 20%, pc based admixture reduce up to 30%.

Fig.8 variation of strength in concrete respect to admixture

Conclusion

Even through, we had a good design, material and scheduling it is impossible to attain strength and durability without good workman ship. For an example Masan will add water in mortar and shovel it. During this process fine partial cement settle down and only sand will available for the plating above. Hence workmanship is more important than any other in construction. For every problem there is a simple solution one of the simple solutions for the corrosion is to provide proper cover to the reinforcement. [8]Nominal cover shall in any case not be less than 40 mm.