Prevention of corrosion in RCC by bacteria

Abstract

Steel gets

oxidise (corrosion) in the present of oxygen and water. Even present of oxygen

in the concrete pore will not cause a corrosion at high alkaline environment.

Concrete contains microscopic pores which contain high concentrations of

soluble calcium, sodium and potassium oxides, this creates alkaline condition

of pH 12–13. The alkaline condition leads to a ‘passive’ layer forming on the

steel surface. The dense passive layer over the reinforcement prevents the

alkalinity. This paper involves in the prevention of corrosion by maintaining

alkalinity in concrete by using bacteria.

Introduction

Corrosion in concrete is majorly due to carbonisation and

chlorination. When concrete carbonates to the level of the steel rebar, the

normally alkaline environment, which protects steel from corrosion, is replaced

by a neutral environment. Under these conditions the steel is not passive and

rapid corrosion begins. The rate of corrosion due to carbonated concrete cover

is slower than chloride-induced corrosion. Occasionally, a lack of oxygen

surrounding the steel rebar will cause the metal to dissolve, leaving a low pH

liquid.

Carbon-dioxide combines with water to form acid in which reduce

the pH of concrete by consuming the calcium hydroxide which is formed in

hydration process of cement, at low pH corrosion begins. Prevention of

carbonization, prevent the alkalinity in which corrosion do not take place.

Chloride in the pore of concrete involves during the corrosion only, it just

acts as the catalyst in the corrosion process. Presence of chloride in concrete

pore is inert at alkaline condition.

Corrosion

process

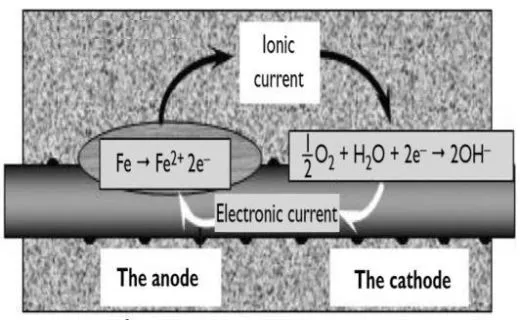

When the passive layer breaks down then rust will start

appearing on the steel surface. The chemical reactions are the same whether

corrosion occurs by chloride attack or carbonation. When steel in concrete

corrodes it dissolves in the pore water and gives up electrons:

The anodic reaction is Fe –> Fe2+ +

2e–

The two electrons (2e) created in the anodic reaction must be

consumed elsewhere on the steel surface to preserve electrical neutrality.

The cathodic reaction is 2e– +

H2O + 1/22 –>2OH–

The ion dissolve in the pore water would not see cracking and

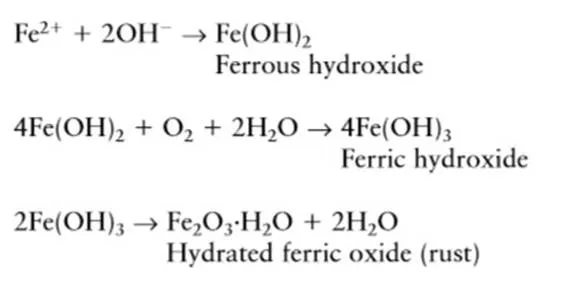

spalling of the concrete. Several more stages must occur for ‘rust’ to form.

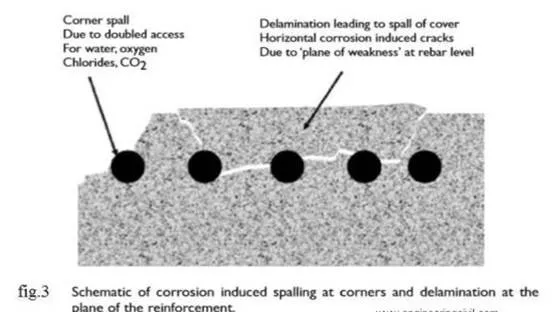

Ferrous hydroxide becomes ferric hydroxide and then hydrated ferric oxide or

rust. This rust cause spalling and crack over the concrete as shown in fig.3.

Fig 1. anode and cathode

reaction of corroding bar

Fe2+ and OH– formed in anode and

cathode combined to form ferrous hydroxide and further undergoes chemical

reaction as below

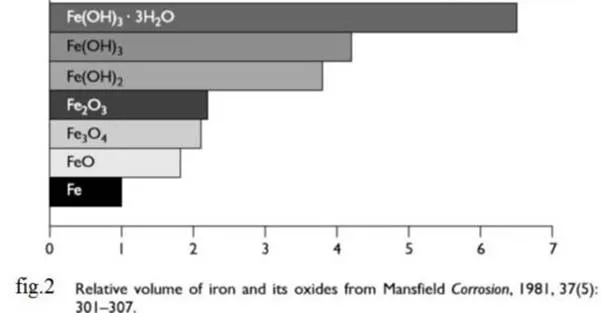

Unhydrated ferric oxide Fe2O3 formed

in the a bow reaction has a volume of about

twice that of the steel it replaces when fully dense. When it becomes hydrated

it swells even more and becomes porous. This means that the volume increase at

the steel/concrete interface is six to ten times . This

leads to the cracking and Spalling as shown in fig.3, that we observe as the

usual consequence of corrosion of steel in concrete and the red/brown brittle,

flaky rust we see on the bar and the rust

stains we see at cracks in the concrete. Fig.2 shows the relative volume of the

iron and its oxide formed in corrosion process.