Manufacturing

in RCC Construction – Prefabricated rebars

Three decades back, a construction site was a place where all

building materials were brought in fabricated or mended as per need and then

used. For example cement, sand, stonechips and

water was assembled at construction site; mixed as per design and used. Brick

kilns were the only manufacturing/ prefabrication done in advance for

construction. Storing of inventory at construction sites wasvery much prevalent.

The concept of factories and automobile industry like ‘lean

engineering’, ‘just in time delivery’ and prefabrication have changed the very

picture of construction site. But till early 2000 prefabrication in

construction rebars was only in concept.

Around 2010 prefabrication of TMT rebars started

in India and now it has become indispensable for both large as well as small

scale project.

In low rise houses like G+1 to G+4 the usual cut and bend

in rebars are stirrups for beams, links for

columns, C-shaped & L-shaped bars for isolated footings and crank bars for

columns. There are primary steel manufacturers in India which provide

prefabrication service for rebars. These

manufacturers also make the commonly used shapes and sizes already available at

retail shops which are only a call away.

Advantages of using prefabricated rebar’s

V/S manually cut and bent material at site

|

Sl. No. |

Prefabricated steel rebar’s |

Site made rings and pieces |

|

1. |

Available in most common sizes. One can

even mix and match the sizes. |

Need based manufacturing, needs lead time

to cut and bend. |

|

2. |

Machine made with accurate shape and size

confirming to IS: 1786 & IS: 456. |

Manually bent at site, expertise depends on

the expertise available at site |

|

3. |

No need of power connection at site for

cutting rebars. |

Mostly electrical equipment are used for

cutting, which is at times dangerous too. |

|

4. |

No on-site bending required |

On-site bending is required |

|

5. |

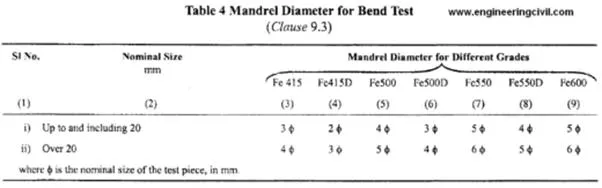

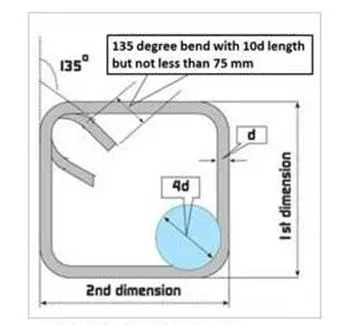

No micro cracks on the bends as proper

mandrels are used |

During manual bending, bar benders ignore

the norms for correct mandrel diameter to be used for bending as per IS:1786. |

|

6. |

Zero wastage of cut lengths |

10% wastage of rebar in quantity |

|

7. |

Available in ready to use bundles at local

steel dealers |

Not applicable |

|

8. |

Need only 2 days to finish concreting

foundation alone |

Need 7 days to finish concreting foundation

alone |

|

9. |

No dependence on labor at

site for cut and bend |

Dependence on availability of skilled labor to cut and bend. |

|

10. |

No pilferage at site |

Pilferage and hence loss of money at site |