Cement Concrete Masonry

Concrete masonry or cement masonry uses cement concrete blocks, either hollow or solid, for wall construction, with or without stone facing.

A hollow unit is defined as that unit that has a core-void area greater than 25% of the gross area.

I came across this textured wall the other day in my stroll around the city and I had to laugh. It is pretty much the architectural equivalent of walking around with your slip showing.

What you see here is hollow clay tile, sometimes known as structural clay tile the precursor to concrete block.

Hollow clay tile was developed in the late nineteenth century as a fireproof technology for building partitions or structural slabs. It was a bit of a misnomer in that it was not a thin tile.

Instead, it was a structural block made of porous terra cotta that was molded into squares or rectangles for walls and floors, or other shapes to encase steel columns or beams.

Each block has hollow cells inside that deaden sound, provide insulation, and keep bugs and rodents out of the wall.

This sheet from the Henry Maurer & Sons catalog dates to about 1898 shows you common sizes and cell arrangements of hollow clay tiles.

Reinforcement brick masonry is analogous. The same deformed steel reinforcing bars used in concrete are placed is to reinforcement concrete construction thickened collar joints to strengthen a brick wall or lintel.

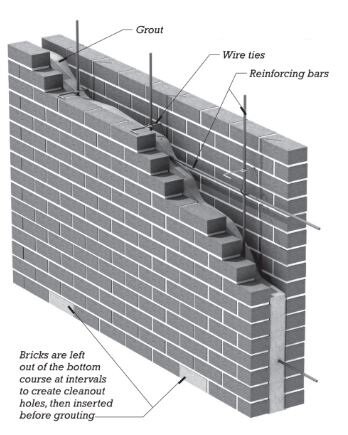

A reinforced brick wall (Show in the figure) is created by constructing two wythes of brick 2 to 4 inches (50-100 mm) apart, placing the reinforcing steel in the cavity, and filling the cavity with grout.

Grout is a mixture of portland cement, aggregate, and water. ASTM 0476 specifies the proportions and qualities of grout for use in filling masonry loadbearing walls.

It is important that grout be fluid enough to flow readily into the narrow cavity and fill it completely.

The excess water in the grout that is required to achieve this fluidity is quickly absorbed by the bricks and does not detract from the eventual strength of the grout, as it would from concrete poured into formwork.

There are two methods for grout-ing reinforced brick walls:

1. Low Lift

2. High Lift

Low Lift

In low-lift grouting the masonry is constructed to a height not greater than 4 feet (1200 mm) before grouting, taking care to keep the cavity free of mortar squeeze-out and droppings, which might interfere with the placement of the reinforcing and grout.

The vertical reinforcing bars are inserted into the cavity and are left projecting at least 30 bar diameters above the top of the brick-work to transfer their loads to the steel in the next lift.

The cavity is then filled with grout to within PA inches (38 mm) of the top, and the process is repeated for the next lift.

High Lift

In high lift grouting, the wall has grouted a story at a time. The cleanliness of the cavity is ensured by temporarily omitting some of the bricks to create cleanout holes.

As the bricklaying progresses, the cavity is flushed periodically from above with water to drive debris down and out through the cleanouts.

To resist the hydrostatic pressure of the wet grout. the wythes are held together by galvanized steel wire lies laid into the bed joints and across the cavity, usually at intervals of 24 inches (600 mm) horizontally and 16 inches (400 mm) vertically.

After the dean out have been filled with bricks and the mortar has cured for at least 3 days, the reinforcing bars are placed and grout is pumped into the die cavity from above in increments not more than 4 feet (1200 mm) high.

To minimize pressure on the brickwork, each increment is allowed to harden for an hour or so before the next increment is poured above it.