Environmentally Safe Blasting & Cleaning

Surface cleaning by dry ice blasting is a very effective method with practically no clean-up required. Equally adaptable to sensitive and rugged surfaces, this is a non-toxic and environmentally friendly method. Read on to learn more about the process, its advantages and applications.

Imagine a situation where you have to sand blast or grit blast a large tank or vessel in or adjacent to an existing industrial plant. Even with a very good protective covering, you can still have the sand and dust settling on all the plant instruments, valves, and other components. The sand and dust gets into the suction flow of fans and blowers. The result can be catastrophic with costly outages, damages, and repairs. Imagine the time and effort required to clean up. The solution? Dry ice blasting.

Even though dry ice has been available since 1925, dry ice blasting is a comparatively new method that is gaining wide acceptance. The first and the most important advantage is that no cleaning is required after blasting.

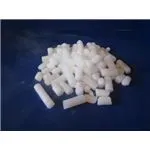

Dry ice is carbon dioxide (CO2) in the solid form. CO2 freezes at -78.5 °C. For blasting purposes dry ice in the form of pellets are used. Production of pellets is by hydraulically compressing the snowlike thick vapors formed when liquid CO2evaporates.

Like sand blasting, the pellets are sucked in by a compressed air ejector and the jet is directed to the surface. Alternatively, it is fed into a compressed air stream and is directed to the surface. On impact, the thermal shock, the thermokinetic energy formed by the rapid expansion of the pellets (almost eight-hundred times worth) breaks down the adherence of impurities on the surface. The result is a clean surface without damage to the surface itself. The sublimation of dry ice pellets leaves no residue from the cleaning media. This one single factor makes it the most attractive surface cleaning method.

Depending on the application, the cleaning force can be gentle or aggressive. In abrasive cleaning, the kinetic force does the cleaning. Not all surfaces can withstand such force, but this is the difference between the two methods.

This is a very environmentally safe method and helps organizations meet ISO 14000 stipulations. Cleaning does not affect the working of adjacent equipment or nearby personnel nor add to any respiratory problems. Since there is no CO2creation, dry ice blasting does not add to the carbon footprint.

The availability and cost of liquid CO2 or dry ice pellets is the only drawback. Even though CO2 is a waste gas, compressing and liquefying it is an energy consuming process. Because of this, liquid CO2 does not come cheap. It is not something that is available off the shelf from hardware shops, nor is it something that can be bought and stored for a long time. If dry ice pellets are not available, a pelletizing machine with a supply of liquid CO2will be required. Even with these constraints, this method is cost effective when one considers zero cost for post cleanup, the reduction in plant down time, and no damages to existing plant equipment.

Precautions for using are to avoid direct contact of dry ice with skin, have eye protection, and make sure that there is enough ventilation in confined spaces.

This link shows a video of dry ice blasting.

Images: Dry Ice Pellets & Blasting Machines

The applications of dry ice blasting are almost unlimited. Following are some of the areas that use this method that hitherto used other methods.

Dry ice cleaning is not by abrasion, but by thermokinetic action. Since dry ice itself is soft, the surface is not damaged. The force required is gentle. This makes it suitable for extremely sensitive applications like cleaning antiques, artifacts, old books and manuscripts. This is becoming a useful tool in historical restoration.

Since CO2 is non-toxic, it is ideally suitable for cleaning in the food industry. Perfect cleaning of all waste, grime and, fat, molds, bacterial formation, fungus and oil can be done in situ by dry ice blasting. Imagine a perfect cleaning of an industrial kitchen in a few minutes, with everything spick and span, and dry.

Cleaning in hospitals is also very effective, as it does not affect patients and sensitive medical equipment. This saves time since the cleaning can be done in situ.

Because of the non-conductive and dry nature of the blasting operation, this method finds considerable application in the electrical industry. Cleaning of electrical appliances, switchgear, insulators, inside of panels, cables, cable trays, relays, and contacts can be done live without a costly power shutdown. Cleaning motors and generators is also very effective since there is no requirement for drying, resulting in shorter down times.

Cleaning plugged HRSG tube bundles, especially finned tubes, and cleaning deposits from turbine blades are some applications in the power plant.

As an effective method of paint removal, this is better than using solvents with disposal problems, or abrasion, which damages surfaces. This can effectively clean corroded surfaces, old paint, tar, asphalt and rust on structures and walls without affecting the functioning of other equipment, and do it all without any post clean-up. Also it is very effective in removing graffiti from walls.

This is the most effective method of cleaning up after a fire, removing smoke and soot marks and the odor of smoke.

Images: Dry Ice Blasting & Clearing Graffiti

Who knows? The next application may be in the laundry, dry cleaning clothes. The day may come when you just walk into the laundry, stand under a dry Ice blasting machine and, wow, your clothes are clean and dry!