Safety & Health Guide for the Chemical Industry

Introduction

More than two thousand deaths from a methyl isocyanate chemical

leak in Bhopal, India, drew world attention to serious hazards in the chemical

industry. Following that tragedy, the Occupational Safety and Health

Administration (OSHA) developed guidelines to aid emplioyers in reducing the

number of potential hazards in chemical industries. This publication is

designed to encourage chemical industry review and safety precautions to guard

against chemical disasters. It contains guidelines used by OSHA compliance

officers to evaluate employer safety programs, particularly in the areas of

disaster prevention and emergency response. It also includes two lists of

acutely toxic chemicals whose presence in the workplace should signal the need

for safety and health measures to protect workers.

The guidelines are aimed at the conditions and processes found in the

"chemical industry," inciuding (but not limited to) firms in SICs 28

and 29. However, they are written to be used in a wide spectrum of workplaces

which produce industrial and consumer chemical products. OSHA also publishes a

manual called "How to Prepare for Workplace Emergencies" which can

help any type of business in developing an emergency plan. A free copy may be

obtained from any OSHA area office.

Disaster Prevention

There are three tasks to perform before any meaningful analysis of

an emergency response system can begin. The first The first task is to identify

the key processes and elements of the production process and to understand how

operational processes are kept within safe bounds under normal conditions.

Conceptually, it is the normal process instrumentation and control measures

that provide the first and greatest degree of protection to plant employees and

to the public. The four areas listed below identify some major subsystems or

components which are commonly found in chemical plants. Each has a bearing on

the safety of operations under normal and emergency conditions.

- A management subsystem which includes management personnel, process specifications, plant design, standard operating procedures, and the written emergency plan.

- A personnel subsystem which assigns and defines roles, for both normal and emergency operations, and provides appropriate training. This may also include labor/management safety committees.

- A physical subsystem which may include transportation systems for materials, ventilation systems, waste removal systems, containment systems, refrigeration systems, storage areas, communications systems, and other process related equipment

- An emergency services subsystem including plant and community components.

A second task is to understand how critical failure points are

identified, and what controls are used to ensure safe operations. This involves

assessing the interrelation of the components and, particularly, identifying

which safety features in the system should be backed up with alternative

instrumentation, procedures, or equipment designed to ensure process variables

are kept within safe limits.

The third task is to identify the emergency response system that is embedded in

the operating system. Conceptually, it is a latent system that is active only

when preventative measures have failed and an incident has occurred. This

system is the most difficult to evaluate because:

- It is not observable except in emergencies.

- The emergency response system also may involve resources and subsystems that lie wholly or partially outside of the physical or managerial boundaries of the chemical plant. For example, local firefighters may supplement in-plant fire brigades; local hospitals may provide care to injured workers in addition to in-plant first aid; local police may be involved with traffic control, evacuating of workers and community, and expediting communications and the flow of emergency and rescue equipment.

- Finally, there is the question of defining the point at which the emergency system "shuts down" and normal operations begin after an emergency.

Plant Management

All the planning and preparation of safe plant operation is

meaningless, unless it can be implemented. In the event of a problem, there is

no time for committee or front office decisions. Correct decisions have to be

made at the lowest organizational level possible, and those decisions have to

be communicated to other affected personnel. This section is intended to

establish whether those elements have been considered in the program.

- Who is in charge? What are the lines of authority under normal operating conditions? in transition times, like during startup and shutdown procedures? In emergencies?

- Can

information be transmitted quickly and easily from: worker to supervisor?

supervisor to worker?

- How is information exchange accomplished during transition periods (starting and stopping work)?

- Is operator jargon commonly and completely understood by those affected by the jargon? Examples: MIC -- methyl isocyanate, Black Betsy -- boiler, Monitor -- stationary firefighting nozzles.

- Are signals clear? Are audible signals distinguishable and understood?

- How has management with requirements of the OSHA Hazard Communication Standard (29 CFR 1910.1200)? Are monitoring records, training records, and material safety data sheets available?

- Standard operating procedures should be examined and discussed. The process of updating these procedures -- including modifications, communication, and training -- should be understood.

- Does a written emergency plan exist? It be discussed with management. It should be understood which contingencies are included in the plan, why they are included, and why management considers them to be adequate for the process, site, and situation.

The Personnel Subsystem

- What are the job classifications of employees who work at the site? Are all job titles present on all work shifts? Are there potentially crucial omissions?

- Are employees aware of their roles during emergencies? Are all critical tasks represented on all shifts?

- Who is responsible for training employees? How often is training provided covering standard operating procedures? Emergency procedures? How is effectiveness of training evaluated by management?

The Physical Subsystem.

It is obviously to see the physical plant and to relate

information contained in operating procedures, emergency plans, and

"blueprints" with actual structures, materials, and processes. In

inspecting the physical plant, the underlying question is "What keeps this

operation -- or this phase of the operation -- within safe limits, including

mechanical and electronic systems, human intervention, and routine maintenance

activity?" Particular attention should be given to:

Plant Layout

Plant layout has some specific safety aspects.

Examples include:

- Separation and isolation

- Chemicals which may react with one another are to be physically separated, oxidizers are to be stored in areas remote from fuel storage.

- Areas of potential explosions storage of explosives, reaction vessels) are to be isolated so if there is an explosion, the damage and risk to employees is minimized.

- Drainage

- Where hazardous liquids may leak or spill from piping or vessels, what provisions are made to prevent their spread to areas where employees may be exposed to the hazard? Examples of possible methods include diking and grading.

- Has the company made any provisions to control unexpected hazardous vapor or gas releases within the drain lines?

- Housekeeping

- Are work areas well maintained?

- Enclosed spaces

- Some processes which are safe in open air may become hazardous if enclosed. If areas of potential or frequent leaks or spills are enclosed to prevent environmental contamination or the spread of the chemicalk, are there adequate precautions to protect employees? Examples include ventilating the room and treating the exhaust; automatically sampling the air in the room or vault; having employees sample before entering the room.

Materials Compatibility

At least two factors should be considered in materials selection:

First, will the contaminate or cause a reaction in the chemicals to be handled

or processed? Second, will the chemicals to be processed attach or destroy the

equipment? For all chemical processes: there are preferred materials;

preferences sometimes are economic, and sometimes they arc based on chemical

reactivity or compatibility. The intent here is to identify readily available

materials that might be used but that are incompatible with the chemicals

involved. (For copper tubing should not be used with acetylene because it

catalyzee a reaction in the acetylene.) These questions are pertinent to

chemicals in all categories (i.e., health, flammability, reactivity). Among

questions to be asked are:

- Are any metals incompatible with the chemicals so that they should not be used for process equipment, piping, or storage systems?

- Are any sealing materials for use in packing (e.g., pumps) or gaskets (e.g., flanges) incompatible with the chemicals so they should not be used in process equipment, piping, or storage systems?

- If incompatible materials are identified; what procedures does the company have to ensure that only acceptable materials are used in new or refurbished equipment? Besides purchase order specifications, is there also inspection by plant personnel to ensure the specifications were followed?

Contamination Control

Potentially reactive chemicals may have their reactions catalyzed

by common materials which easily enter systems whenever seals are opened.

Examples include water or rust which may easily enter a system during transfer

from one vessel to another, either during hookup or disconnect, or during

pressurizing or venting of tanks.

- If such potential catalysts are identified, how are they excluded from the system? Examples include:

- If vessels are pressurized by inert gases, are there filters in the gas lines to remove solid particles?

- If vacuum relief or pressure relief valves are on the vessels, how are they protected so potentiaiiy hazardous contaminant can enter through them when open?

- When systems are opened for maintenance purposes, what precautions are taken to prevent contamination? What is done to safeguard the system while it is open? What precautions are taken to ensure that replacement parts are free of contaminants incompatible and/or incompatiablematerials? When connections are made and broken (e.g., during transfer from rail cars or trucks), what measures are taken to ensure contaminants do not enter the system?

Physical Facilities

Much plant equipment could be considered ancillary to the

production processes. Examples of systems that may need to be present, properly

inspected, and functional are:

- Emergency eye wash or shower.

- Fixed fire suppression equipment.

- Portable firefighting equipment, if employees or a fire brigade are to use portable firefighting equipment.

Questions to be asked about these systems include: How often are

they tested? What capacity do they have? Is the capacity sufficient for the

anticipated emergency?

Inspection and Maintenance

All equipment must be shut down sometime, no matter how

infrequently. When safety systems are shut down, what backup systems or

procedures are available to provide replacement protection (e.g., stop process

until safety systems are available again)? If shutoff valves can isolate safety

relief valves, what measures ensure that the system is protected from

over-pressurization (e.g., person stationed to monitor pressure)? What system

is in place to ensure that maintenance of critical safety features are

corrected immediately? What ensures that less critical features are corrected

within a reasonable period?

Pressure vessels also need periodic inspection and testing because of normal

wear and potential corrosion either at welds or in the base material. The

combination of pressure and volume determine the hazard: high volume, low

pressure systems can have the same potential energy for release as low volume,

high pressure systems.

When potentially corrosive chemicals are used (e.g., acids, caustics), or the

plant atmosphere is corrosive (e.g., near the ocean, or from chemical releases

within the plant), what measures are taken to ensure system integrity? Examples

include periodic pressure testing, x-ray, etc.

General Containment and Controls

During normal operations it is difficult if not impossible to keep

material completely in a closed system. Vacuum must be relieved when a liquid

level drops, and pressure must be relieved when the tank is refilled. For

toxic, flammable, and reactive chemicals, the questions to be asked focus on

minimizing such necessary releases and rendering the released chemicals

harmless before discharge to the atmosphere. Examples of questions to be

pursued include:

- Where do emergency relief vents discharge? Are they piped to scrubbers, neutralizers, incinerators, precipitators, etc. to remove hazardous materials?

- What precautions are taken to minimize spills when connections are broken? Is the line purged prior to the disconnect? Are purge gases treated? Are quick disconnects used? Do employees wear personal protective equipment (PPE) when disconnecting? Is there a dike or some method to collect and contain small spills or releases? Is the area ventilated and is ventilated air treated?

Material Handling

As long as chemicals are maintained in a closed system, they are

safe and harmless. Chemical processes using hazardous chemicals should be

designed to maintain that closed system. After design and maintenance, the only

potential problems are: introduction of raw into the closed system and the

removal of products (either the desired product for shipment or waste) from the

closed systems. This section deals with those hazards.

- How are raw materials received and shipped?

- Are raw materials transfers accomplished in a closed system?

- Who performs transfer (company or shipper)?

- Is the system pressurized or blanketed?

- Do critical systems have connections that are not interchangeable? Examples: potable water wtih process water? water and reactive chemicals? incompatible reactive chemicals?

- How are unwanted products disposed of:

- Vents: are vents properly directed?

- Flare towers?

- Scrubbers?

- Ditches: properly lined? Where do they drain?

- Tertiary treatment?

- Are provisions made or considered to preclude incompatible chemical mixing in waste drainage?

Instrumentation

Suitable controls and instruments should be provided for both

normal conditions of operation and for emergencies. Instrumentation includes

sensors, indicators, recorders, and transmitters for measurements such as

temperature, pressure, flow, liquid level, and analysis.

Many self-acting control devices, such as pressure regulators, normally fail in

the open position, which may be the unsafe position. In such cases, emergency

backup controls should be provided. In the case of pressure regulators, this

includes pressure relieving devices down-stream and automatic shutoff valves interlocked

with excess pressure switches.

- Do

instruments and controls consider failure in their design?

Examples: Control valves should be arranged so that, on loss of instrument air or actuating power, they will go into the safe position. Where loss of instrument air or power could lead to an unsafe condition, emergency air or power supplies should be provided. - Are instruments made of material capable of withstanding the corrosive or erosive conditions to which they are subjected?

- Do instrument sensors measure the true status of the system they are designed to protect or control?

- Examples: In a large reactor, many thermocouples may be needed since the temperature may not be uniform throughout. In sensing liquid flow through a pipe, a flow switch in the pipe is more reliable than monitoring power supply to a pump.

- Are grouped instrument leads and control locations protected against exposure to explosion, fire, or toxic chemicals where they are critically needed to shut down the process safely? In addition to normal controls, are accessible emergency controls provided by which pumps or automatic valves controlling the flow of flammable liquids could be operated in event of fire?

- Are all indicating dials, indicating lights, recorders, alarms, and switches which affect process safety conspicuously labeled as to their function and meaning?

- Are instruments constructed and installed so that they can be easily inspected and maintained?

- Are separate safety control and interlock systems relied upon rather than relying on the production process control system for safety supervision of the process?

- Are instruments in hazardous areas (as defined in National Electrical Code) intrinsically safe or or enclosed so that they will not act as ignition sources?

- Are critical measurements recorded (as is preferable) rather than merely indicated by lights or dials so that rate of change in processes will be more readily evident, and greater management supervision can be maintained over operator practices?

- Do important control valves have steel bodies and are they yoked to withstand fire exposure, impact, and vibration?

- How often is routine maintenance or replacement performed on key instruments?

Piping Systems

Piping and instrument diagrams are used to follow the formulation

or reaction process and also to check safety devices and system protections.

Questions that may be asked include:

- Do reaction vessels, storage tanks, or pressure vessels have safety relief devices to prevent over-pressurization?

- Are there shutoff valves that can render safety relief devices ineffective? If so, what additional precautions are taken?

- Where do materials vent when released through the safety relief devices?

- If there is a loss of electrical or pneumatic power, do controls fail in a mode that is safe?

- Will instrumentation detect leaks and spills? (E.g., when material is being pumped from one vessel to another, is there any check to assure that as the level falls in one vessel, it rises in the other?)

- Are temperature or liquid level controls or alarms provided?

- Are piping, valves, and fittings designed according to the recognized standards for the working pressures, temperatures, structural stresses, and chemical conditions to which may be subjected? Is non-destructive testing conducted routinely to ensure that minimum wall thicknesses are maintained?

- Is piping well-supported and protected against physical damage?

- Are pipe lines for reactive chemicals pitched to drain, with drain valves at low points?

- Are main shutoff valves which can affect the safety of the system conspicuously labeled?

- Do shutoff valves indicate their "open" or "shut" position?

- Where improper operations or leaking of valves can lead to a hazardous situation, are interlocked valves or double valves and vents used to minimize hazard?

Protective Systems (not quality control)

- Heating or cooling systems may be for product control or for safety control. Cooling may be necessary to prevent a runaway reaction in reaction vessels. Reactive chemicals also may be cooled in storage to provide more time to respond to an initiated reaction.

- What protective devices are there for the heating or cooling systems? temperature alarms? backup systems or redundancies? procedural controls?

- Are heat transfer materials for heating or cooling incompatible with reactive materials?

- Is refrigeration automatically actuated in emergencies?

- Are manual valves located in safe areas?

- Are intermittent power failures considered and backup provisions implemented?

- Are there explosion suppression systems? How are they tested and maintained?

- Are systems inerted to exclude contaminants which may be catalysts or reactive materials? Examples include:

- Passivating vessels and piping or components (before system startup).

- Providing an inert gas atmosphere such as a nitrogen blanket on flammable materials.

- Submerging reactive materials (such as sodium in kerosene).

Fired Systems

Do furnaces and heaters have:

- Adequate draft?

- Positive fuel ignition?

- Combustion safeguards?

- Fuel controls?

- Water or liquid level indicators?

- Pressure relief devices?

- High temperature alarms?

- Emergency shutoff facilities?

- Backflow protection?

Electrical Equipment

All wiring and electrical equipment in chemical plants must be installed in

accordance with the National Electrical Code. Equipment used must be approved

where applicable.

- Proper installation and maintenance is essential.

- Adequate clearance or insulation should be provided between conduits and hot surfaces to prevent damage to the wiring insulation.

- Equipment must be properly grounded and/or bonded in hazardous areas to minimize static electricity, both within and outside of equipment. Are other appropriate steps taken to prevent buildup of a static charge?

- Equipment should be shielded from lightning by protective ground wires, rods, or masts.

Pressure Vessels and Storage Tanks

The design and construction of pressure vessels and storage tanks must be in

accordance with accepted engineering principles.

- Pressure vessels must be designed and constructed in accordance with appiicabie codes, standards, state and local laws, and regulations.

- Vessels should be equipped with overpressure protection as required. Vents should be arranged to discharge to a point where ignition of escaping vapors or liquids will not seriously expose personnel, the equipment, or structures. Relief devices hould be kept free of corrosion or fouling and should be operable at all times.

- Often an intert atmosphere is maintained in a vessel or tank to keep the atmosphere out of the flammable range. The consequences of contamination or failure to use an inert gas should be analyzed and equipment or procedures should be devised to cover the situation.

- Unprotected sight glasses should be avoided in process equipment wherever possible.

- Storage tanks be designed based on the quantity, pressure, reactivity, and corrosiveness of the material stored. The design should inciude overpressure equipment and vents and should consider the interrelationship of each part of the overall system, e.g., the effect of a gasket which blows out at 25 psi at one point in the system when the relief valves are set at 60 psi.

Pumps and Compressors

Pumps and compressors are the work horses of chemical plants for

moving every type of liquid and gas.

- Failure of moving parts or packing glands can cause escape of flammable or toxic liquids or gases. Remotely controlled switches and shutoff valves are needed to control the flow of fuel in an emergency.

- Equipment used for transfer of flammable vapors or gases should be installed to minimize vibration and thus to avoid loosening of fittings and joints.

Response to Emergencies

General Principles

Assessing the adequacy of a written emergency plan is an art, not a

science. It involves judgment as to the reasonableness of the assumptions

underlying the plan (e.g., what is a reasonable worst-case estimate?) as well

as the adequacy of countermeasures designed to protect life and to limit

environmental and property damage.

A few general principles may be useful in approaching this task:

- Are the priorities of the plan clearly stated as to -- safety of plant personnel and the public? control of hazard? minimizing damage to property?

- Does the plan deal with with reasonable accident scenarios (minor incident to "worst case")?

- Is the plan practical?

- Is the plan simple?

- Is the plan easy to understand?

- Will it deal with any type of emergency? For example, are contingencies included for: fire and explosion? release of highly toxic materials? large chemical spills? acts of nature? sabotage including bomb threats, etc.?

- Has attention been given to emergencies which may occur during inclement weather?

- Is the plan updated periodically, e.g., annually or whenever processes, procedures, or key personnel change?

- Are there emergency drills or simulations involving all members of the response team including public agencies?

- Are responses reviewed to determine areas where improvement is needed?

- How are the results of the drill evaluations communicated to the employees?

- Are drills conducted for all shifts?

- Are safety responsibilities a "critical element" in supervisors' performance standards? For example, how is safety performance considered relative to production demands and is it factored into performance appraisals?

- Has plant management worked with community leaders to develop an appropriate public response plan?

Control and Coordination

When assessing the adequacy of a written emergency plan, questions

concerning control and coordination include:

- Will one person be designated to coordinate all efforts? Is there always an individual onsite who has been trained and has the ability to take the initial actions necessary to minimize the emergency?

- Has there been prior consideration/coordination of all potential response groups or agencies such that there will not be loss of control due over-or underresponse?

- Does the the safety committee have oversight relative to the plan? Are employee representatives an integral part of the committee? Are members involved in plant audits? How do they receive feedback on action taken relative to their recommendations?

- Has the plan been distrubited to:

- All key personnel up and down the company chain of command including employee representatives and the switchboard operator?

- Police officials?

- Fire officials and paramedics?

- Local government?

- Hospitals and physicians?

- Mutual aid industries?

- Utility companies?

- When changes are made in the emergency plan, have provisions been established to communicate those changes to individuals with a need to know?

- What wnat mechanisms exist to allow the reporting of unsafe acts or unathroized employees in high hazard areas?

- Will a control center be established in a safe location? Alternatively: are process control centers already established in safe locations, with appropriate architecture and support systems?

- Are procedures in place for notifying transient personnel on the site, such as delivery and shipping services, an emergency through the most likely site contacts (e.g., shipping, receiving sections)?

- Are emergency rosters and call out plans developed?

- Are emergency service listings and phone numbers developed and distributed? Does the switchboard operator have a copy? Do all phones have a brief listing of immediately needed emergency numbers posted on them?

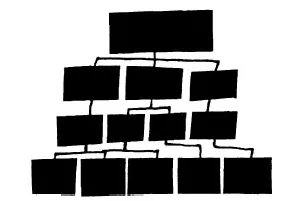

- Are organizational charts developed and distributed for day-to-day operators and emergency operators?

- Are lists of raw materials, intermediates, products, and their locations within the plant provided with the plan?

- Are the associated hazardous chemicals listed in accordance with the OSHA Communication Standard?

- Are flammable, reactive, physical, radioactive, and other hazards listed?

- Are appropriate disposal methods listed?

- Are current maps, flow diagrams, and blueprints part of the plan? overall site map? adjoining city and/or state maps including local topography?

- Will additional security be needed and planned for?

- Will strict accountability of personnel entering and leaving the area be maintained?

- Will only authorized personnel be granted entry?

- Will traffic control be a problem?

- Are certain areas of the site more vulnerable to sabotage?

Procedures

The questions concerning the procedures set forth in a written

emergency include

- Are condensed instructions (such as checklists for evacuation or shutdown) part of the written plan?

- Are designated duties and alternate duties of each person clearly and briefly described? Are vacations, holidays, weekends, and 2nd and 3rd shift situations considered?

- Have procedures been established for employees who remain on site to perform critical operations during emergency situations?

- Have responsibilities and procedures been established for those who are assigned rescue or firefighting duties? Are these employees required to take physical examinations which demonstrate their fitness to perform such duties? If so, how frequently are these examinations administered?

- If the company has elected to use a fire brigade are the appropriate requirements of 29 CFR 1910.156 being met?

- What is the company's position on the use and availability of fire extinguishers?

- Are rescue teams formally trained in search and resuce procedures? Are they familiar with the location of utility disconnects and all evacuation routes? Are they provided with appropriate PPE and trained in first aid/emergency medical treatment? Are they provided with communication equipment? Are resuce/response personnel provided with a properly equipped vehicle(s) to reduce response time?

- Are documents readily available for reference in an emergency? Are decision logic (decision making) charts (or other eoduments) furmulated for planning and executing the following activities:

- Selection of protective clothing?

- Selection of respiratory protection?

- Emergency shutdown of equipment?

- Evacuation of the plant?

- Evacuation of the surrounding populace?

- How did management arrive at these decisions?

- Have definite volumes of air contaminants been established which, when released, trigger either onsite and/or offiste emergencies?

- Have dispersion models been calculated to assist in planning of evacuation? If not, how does management deal with a hazard that is sperading into new areas of the plant and the community?

- Are employees or recovery personnel trained and are procedures in place for monitoring the site and adjacent areas to identify levels of contaminants as well as their location (atmosphere/land/water) and direction of travel.

- Is emergency equipment provided in adequate quantities and placed in useable locations; e.g., emergency power generators for emergency lighting and shutdowns; pumps and valves located for supplying water to fight fires; PPE, safety showers connected to alarms, etc.?

- Is emergency equipment checked, tested, and calibrated periodically for operational readiness?

- Are personnel trained and experienced in its use?

- Is emergency equipment of appropriate type for any emergency which may occur?

- Are local emergency response personnel brought into the site periodically for familiarization?

- Are potential problem areas and processes pointed out and discussed?

- Are locations where personnel normally work pointed out?

- Are primary and backup tow-way communication systems developed and in place? Are they vulnerable to power failure or other disruption? Do ambient plant noise levels interfere with voice communication?

- Is mutual aid equipment that might be borrowed in an emergency compatible with site equipment?

- Is there a written spill control plan, e.g., containment, neutralization, disposal, appropriate PPE, etc.?

- Are incompatibilities of released material anticipated?

- Are

normally innocuous materials likely to become hazardous due to an

emergency? For For example, any materials which are water reactive would

influence the method of firefighting; certain materials when heated

release hazardous levels of toxic substances not existing during normal

conditions, etc.

Are hospitals, physicians, and other medical/paramedical staff provided with: - Lists of hazardous chemicals and Material Safety Data Sheets?

- Acute symptoms?

- Delayed symptoms?

- Bioassay tests?

- Special treatment required?

- Have local health care professionals been involved in the development or review of theplan?

- Is public information planned and is one person designated as spokesperson to avoid speculation and panic? coordinated with other responding groups?

- Are there formal accident and near-miss investigation responsibilities and procedures developed? What is the policy on investigating injury versus non-injury accidents? Are reports required? Are causal analyses performed?

- Has any consideration been given to potential sewer contamination during an emergency/disaster, e.g., introduction of or toxic materials into the system?

Recordkeeping Requirements

The Secretary of Labor has said that "the cornerstone of any

successful, effective safety and health program is accurate and complete

recordkeeping." Because of its importance, OSHA places special importance

on recordkeeping.

Employers of 11 or more employees must maintain records of occupational

injuries, illnesses. and deaths as they occur. The purposes of keeping such

records are to inform employees of the effectiveness of their employer's safety

and health program, to permit the Bureau of Labor Statistics

to complete survey material, and to help define hazardous industries.

In addition, while the following items are not required for all OSHA standards,

they should be recorded to accurately monitor and assess occupational hazards.

Initial and periodic monitoring, including the date of measurement,

operation involving exposure, sampling and analytical methods used and evidence

of their accuracy: number, duration, and results of samples taken: type of

respiratory protective devices worn: and name, social security number, and the

results of all employee exposure measurements. This record should be kept for

30 years.

Employee physical/medical examinations, including the name and social security

number of the employee; physician's written opinions: any employee medical

complaints related to exposure to toxic substances: and information provided to

the examining physician. These records should be maintained for the duration of

employment plus 30 years.

Employee Training. These records should be kept for one year beyond the last

date of employment by that employee.

All records should be made available, upon request, to the OSHA

Assistant Secretary, the Directory of NIOSH, affected employees, former

employees, and designated representatives.

Training

An adequate emergency plan will address a training program. The following

questions apply:

- Are supervisors trained periodically? Are front line supervisors and employees involved in plan review and development in their areas?

- Have employees and front line supervisors been trained in the recognition of early warning signs (e.g., unusual odors or sounds, signs and symptoms of exposure, unusual vessel temperature or pressure readings, leaks, vibraion, etc.)?

- Is safety and emergency plan training provided to all new employees and all other employees who assume a new job? How often is emergency response training repeated?

- Are front line supervisors involved in training employees? To what extent?

- Is there a method to evaluate training?

- Are contractors who come on site required to undergo specific training in hazards and precautions?

Evacuation

It is essential that an effective plan for evacuation of during an emergency

situation be included in the overall written emergency plan. Questions

concerning this aspect of the plan include:

- Are decision logic charts available such that supervisors on each shift could make an informed decision to evacuate the site?

- Are decision logic charts available such that the supervisors on each shift could provide local authorities the information necessary to decide when to evacuate the surrounding population?

- Has cooperation of the local weather bureau been coordinated to predict temperature, winds, inversion levels, and other meteorologic conditions that could affect gas or vapor concentrations?

- Are formulas or dispersion models provided for calculating concentrations of air contaminants down wind?

- Have evacuation routes inside and outside the plant been planned and coordinated with local authorities?

- Have employees and the local populace been informed of the routes to be used?

- Are primary and alternate evacuation routes clearly indicated in the plan?

- Are detection and alarm systems provided, e.g., for fire or toxic release?

- Are there any periodic checks to ensure that detection and alarm systems are maintained in operable conditions?

- Do alarm systems meet the requirements, as appropriate, of 29 CFR 1910.165?

- Are evacuation instructions and signals for evacuation clear and understood by employees and by the surrounding popuiace?

- Have provisions been made for the evacuation of handicapped persons?

- Have "safe distances" been considered when regrouping areas were designated?

- Have evacuation wardens been designated?

- Are supervisors on each shift capable of executing the entire plan on their own?

- Are employees instructed to proceed to regrouping points located cross wind from the source and at a "safe distance" from the danger zone? Are the regrouping points well known by employees? Have restrictive topographical conditions been considered?

- Is there a wind sock or wind vane on the site to determine wind direction?

- Is a complete copy of the emergency plan located in a safe place?

- Are adequate supplies and equipment located at these points?

- Are key personnel designated to make accountability checks at the regrouping points and to report the medical conditions of present and the names of those missing?

- Are adequate communication systems available at these points?