Column Operation

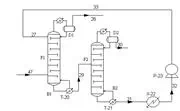

The extractive distillation unit of this cyclohexane production plant consists of two distillation columns (Figure 10), which we can easily classify as direct sequence columns. The first column acts as an extractive column where the solvent is introduced at the second stage of the column, so that it will be present throughout the column and exits with the bottoms. As were stated above, the solvent alters the natural volatility of the binary mixture by forming hydrogen bonds with benzene and allowing it to be recovered as the bottom product.

The bottom product of the first column will then fed to the second column, i.e. the solvent recovery column, to undergo the normal distillation to separate both the components for further usage, i.e. benzene being recycled to the reactor for further conversion while solvent to the first column for reuse. The main operation parameter of the distillation unit is shown in Table 5.

|

Unit Operation and Stream |

Description |

Operating Parameters |

|

Distillation Column |

||

|

T-20 |

First column (extractive column) |

Operating pressure: 150 kPa Number of trays: 45 Solvent (str. 27) feed tray: 2 Feed (str. 47) tray = 28 |

|

T-21 |

Second column (solvent recovery column) |

Operating pressure: 105 kPa Number of trays: 20 Feed stream: 10 |

|

Heat Exchanger |

||

|

X-22 |

Cool down the solvent for recycling |

Outlet temperature: 80 °C |

|

Pump |

||

|

P-23 |

Pump the solvent for recycling |

Outlet pressure: 150 kPa |

|

Stream |

||

|

Stream 27 |

Solvent stream of 1,2-propanediol |

Molar flow rate: 3600 kgmol/h |

|

Stream 47 |

Feed stream |

Molar flow rate: 355.43 kgmol/h |

|

Stream 28 |

Product stream of Column T-20 distillate (cyclohexane) |

Molar flow rate: 158.75 kgmol/h with a purity of 99.3% |

|

Stream 29 |

Benzene solvent stream of bottom product from column T-20, fed to solvent recovery column T-21 |

Molar flow rate: 3795.5 kgmol/h with a purity of 94.8% |

|

Stream 30 |

Product stream of column T-21 distillate (benzene) for recycle |

Molar flow rate: 223.91 kgmol/h with a purity of 84.96% benzene |

|

Stream 31 |

Solvent stream of bottom product from column T-21 (solvent) for recycle |

Molar flow rate: 3571.6 kgmol/h with a purity of 99.87% solvent |

Â

|

|

|

Figure 10: Extractive Distillation Unit for Cyclohexane Production Plant |

Â

Â

|

|

|

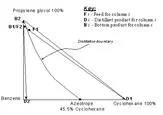

Figure 11: Distillation Ternary Diagram for the Extractive Distillation Unit |