Distance Between Mist Eliminator Top And Vapor Outlet Nozzle For Vertical Separators

Besides defining the Low-Low (LLL), Low (LL), Normal (NLL), High (HLL) and High-High (HHLL) liquid level based on criteria such as retention time, surge requirements for normal process control and adequate disengagement space during events such as large liquid slugs entering the separator or foaming, it is also important to define the vapor outlet nozzle distance from the top of the mist elimination device.

The objective of providing a minimum distance between the mist elimination device and the vapor outlet nozzle is to prevent channeling by promoting equal velocities across the entire surface area of the mist elimination device.

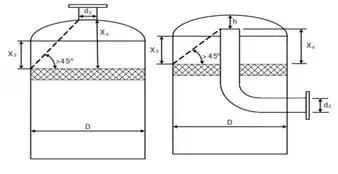

Refer the sketch below for two separate configurations of mist eliminator and vapor outlet nozzle for vertical gas-liquid separators:

The vertical distance X4 is the minimum distance required between the mist eliminator top and the outlet nozzle and is given by:

X4 ≥ (D - d2) / 2 -------------(1)

Also

h ≥ d2 ------------------(2)

where:

X4 = vertical distance from mist eliminator top to vapor outlet nozzle as shown in sketch

D = Outside diameter of vessel

d2 = Outside diameter of vapor outlet nozzle

Some standards recommend that X4 should be a minimum of 12 inches even if the calculated value as per equation-1 is less than this value.