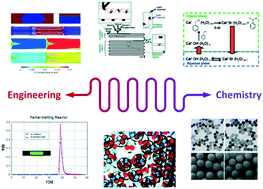

Liquid僕iquid microflow reaction engineering

Abstract

Microflow reaction is important for the miniaturization of chemical devices and systems. From an engineering perspective, excellent characteristics, including narrow residence time distribution, rapid reactant mixing, fast mass and heat transfer, and effective droplet morphology control, of segmented liquid僕iquid flow in microspace are summarized in this review based on recent research progress in the areas of microfluidics, flow chemistry, micro total analysis, and microreaction engineering. Via engineering, important roles of segmented liquid僕iquid flow, such as improvements in production yield, inline purification of intermediates and products, creative droplet reactors, and preparation of particle materials with various structures, are introduced. The scale-up of micro devices and large-scale production of chemicals through microflow technology are also discussed, showing good prospects in research and industrial application.

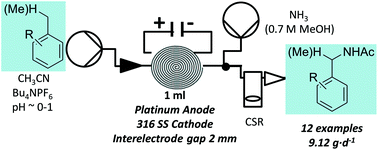

Continuous direct anodic flow oxidation of aromatic hydrocarbons to benzyl amides

Abstract

The continuous production of benzyl amides by anodic oxidation in flow was developed. The stability and productivity of the equipment was examined over time and monitored by means of in-line UV analysis. The applicability of the method to twelve substrates was demonstrated.

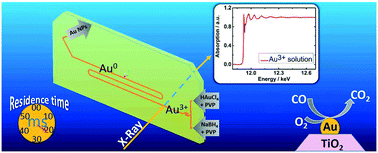

Continuous microfluidic synthesis of colloidal ultra small gold nanoparticles: in situ study of the early reaction stages and application for catalysis

Abstract

A continuous microfluidic setup was developed to study colloidal synthesis of gold nanoparticles using tetra chloroauric acid as precursor, sodium borohydride as reducing agent and PVP as stabilizer. The setup consists of pressurized vessels that allow pulsation-free flow of reactants and a microfluidic chip with integrated micromixers essential for efficient mixing with small mixing time (2 ms) followed by a meandering microchannel. The microfluidic chip enables recording X-ray absorption spectra (XAS) in situ at different positions along the microchannel at high flow rates approaching turbulent mixing conditions and thus to correlate reaction time with changes in the nanoparticle structure. Significant contributions of oxidized gold could be observed after the first 6 ms of the reaction, whereas after 10 ms principally all gold appeared to be in a metallic state. The nanoparticles obtained were characterized ex situ by various complementary techniques. The resulting nanoparticles had average diameter of 1.0 nm and narrow size distributions compared with those produced in a batch reactor. Depositing the nanoparticles on TiO2resulted in catalysts with two different Au loadings (0.7 and 1.7 wt% Au/TiO2) which exhibited good CO oxidation activity.

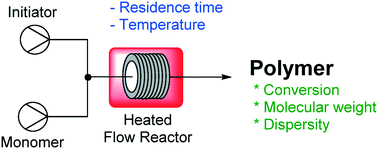

Continuous flow synthesis of poly(acrylic acid) viafree radical polymerisation

Abstract

The free radical polymerisation of aqueous solutions of acrylic acid (1) has been studied using a continuous flow reactor to quickly screen reaction parameters such as temperature, residence time, monomer- and initiator concentration. The experimental data sets produced established a theoretical basis for conducting scale up processes to efficiently produce larger quantities of poly(acrylic acid) delivered with good control over the molecular weight and dispersity.