Kinetics of nanocrystal synthesis in a microfluidic reactor: theory and experiment

Abstract

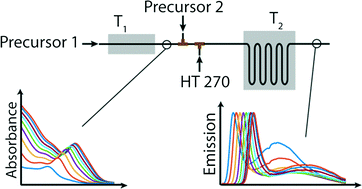

The processes occurring during nanocrystal nucleation and growth are currently not well understood. Herein, we theoretically and experimentally investigate the growth kinetics in colloidal nanocrystal synthesis. Using a novel microfluidic reactor integrating independent modules for nucleation and growth, we demonstrate the controlled, direct synthesis of high quality nanocrystals in high yield. For CdSe nanocrystals, we find that size tuning solely by variation of the reaction time and temperature does not yield product populations of optimal size dispersion or yield. Instead, we present an improved method for the synthesis of bespoke nanocrystals that relies on the controlled addition of precise amounts of additional precursor subsequent to nucleation and fine tuning of the reaction time and temperature in the second stage. Real-time spectroscopic monitoring of the produced crystals in conjunction with kinetic simulations confirms the close correspondence between the model and the experiment and elegantly quantifies the effects of temperature, concentration, additives and surfactants on conversion, growth and diffusion rates within the model framework. We show that the conversion of the precursor to a monomer follows a first order rate law and that the growth rate has a stronger temperature dependence than the conversion rate. Moreover, the surfactant concentration retards the reaction by inhibiting diffusion to the growing crystals whilst maintaining a uniform conversion rate. Finally, we demonstrate that diphenylphosphine, a common additive in CdSe synthesis, enhances the reaction rate by accelerating precursor conversion.

Carbon monoxide where you want it, when you want it

Synthetic chemists have invented two new room temperature methods for generating carbon monoxide from cheap precursors and using it straight away, so that deadly amounts of the gas never build up.

Carbon monoxide is toxic, flammable and disperses fast in air. It also happens to be one of the most useful C1 building blocks for organic synthesis. Important industrial processes use bulk quantities. But concerns over safety, especially in cylinder storage and transportation, are hampering research. Carbon monoxide surrogates do exist, but involve costly components, high temperatures or harsh conditions.

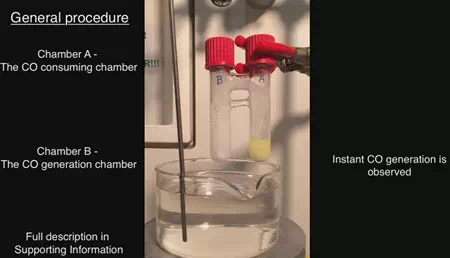

To generate carbon monoxide at the point of use, Wim De Borggraeve and coworkers at KU Leuven, Belgium, have devised a triple system of cheap and common mesyl chloride, triethylamine and formic acid. Alternatively, collaborative work between the groups of Steven Ley at the University of Cambridge, UK, and Trond Ulven at the University of Southern Denmark, brings together chemistry developed in Denmark with flow chemistry technology from Cambridge.