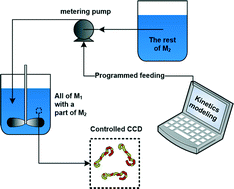

Progress in reactor engineering of controlled radical polymerization: a comprehensive review

Abstract

Controlled radical polymerization (CRP) represents an important advancement in polymer chemistry. It allows synthesis of polymers with well-controlled chain microstructures. Reactor engineering is essential in bringing lab-scale chemistry to industrial realization. This paper reviews the research progress in reactor engineering of CRP, namely, atom transfer radical polymerization (ATRP), reversible addition–fragmentation chain transfer radical polymerization (RAFT), and nitroxide-mediated or stable free radical polymerization (NMP or SFRP). Research activities in semi-batch reactors, tubular reactors, and continuous stirred-tank reactors (CSTR) of both homogeneous (bulk and solution) and heterogeneous (emulsion, mini-emulsion, heterogeneous catalyst, etc.) CRP systems are summarized. Typical examples are selected and discussed in detail. Perspectives on the current status and future development are also provided.

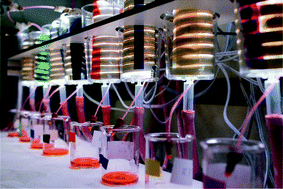

A convenient numbering-up strategy for the scale-up of gas–liquid photoredox catalysis in flow

Abstract

Visible-light photocatalysis is a mild activation method for small molecules and enables a wide variety of transformations relevant for organic synthetic chemistry. However, one of the limitations of photocatalysis and photochemistry in general is the limited scalability due to the absorption of light (Lambert–Beer law). Here, we report the development of a convenient numbering-up strategy for the scale-up of gas–liquid photocatalytic reactions in which the gas is consumed. Only commercially available constituents were used and the system can be rapidly assembled by any practitioner of flow chemistry. The modular design allows us to systematically scale the photochemistry within 2n parallel reactors (herein, n = 0, 1, 2, 3). The flow distribution in the absence of reactions was excellent, showing a standard deviation less than 5%. Next, we used the numbered-up photomicroreactor assembly to enable the scale-up of the photocatalytic aerobic oxidation of thiols to disulfides. The flow distribution was again very good with a standard deviation lower than 10%. The yield of the target disulfide in the numbered-up assemblies was comparable to the results obtained in a single device demonstrating the feasibility of our approach.

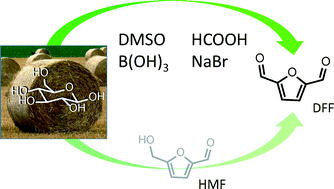

Simple efficient one-pot synthesis of 5-hydroxymethylfurfural and 2,5-diformylfuran from carbohydrates

Abstract

2,5-Diformylfuran (DFF) and 5-hydroxymethylfurfural (HMF) are interesting platform compounds in the chemical industry. A sustainable one-pot procedure is reported for the transformation of carbohydrates into DFF. Mono-, di- and polysaccharides as well as crude biomass (straw and bran) have been transformed. Depolymerisation, glucose isomerisation to fructose, fructose dehydration and finally oxidation of HMF to DFF are involved. The optimised catalytic system contains boric acid in DMSO for HMF synthesis. Addition of sodium bromide and formic acid to the reaction mixture leads to the formation of DFF. Boric acid is mainly involved in depolymerization, isomerisation and dehydration. Large amounts of boric acid lead to the degradation of HMF. NaBr and water are involved in the selective oxidation of HMF. Formic acid is involved in the dehydration step and it accelerates the oxidation of HMF.