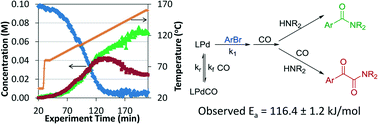

Kinetics analysis and automated online screening of amino carbonylation of aryl halides in flow

Abstract

Temperature, pressure, gas stoichiometry, and residence time were varied to control the yield and product distribution of the palladium-catalyzed aminocarbonylation of aromatic bromides in both a silicon microreactor and a packed-bed tubular reactor. Automation of the system set points and product sampling enabled facile and repeatable reaction analysis with minimal operator supervision. It was observed that the reaction was divided into two temperature regimes. An automated system was used to screen steady-state conditions for offline analysis by gas chromatography to fit a reaction rate model. Additionally, a transient temperature ramp method utilizing online infrared analysis was used, leading to more rapid determination of the reaction activation energy of the lower temperature regimes. The entire reaction spanning both regimes was modeled in good agreement with the experimental data.

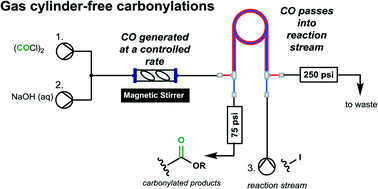

Controlled generation and use of CO in flow

Abstract

A method for the generation and use of carbon monoxide in flow chemistry has been developed. By using a tube-in-tube reactor, oxalyl chloride can be conveniently and safely hydrolyzed using a NaOH solution to generate CO in the outer stream, which then passes through AF-2400 semi-permeable inner tubing to enrich a reaction stream where it is consumed. The tube-in-tube reactor allows the generation of CO under conditions which would otherwise be incompatible with the reaction conditions. In this way carbonylations can be successfully performed in flow without the use of pressurized gas cylinders. Both alkoxy- and aminocarbonylation was carried out in flow, including a 320 minute continuous run, as proof of concept.

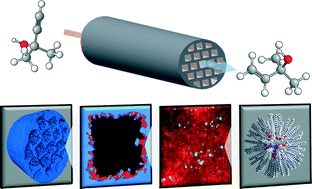

Structuring hybrid palladium nanoparticles in metallic monolithic reactors for continuous-flow three-phase alkyne hydrogenation

Abstract

Palladium nanoparticles modified with the hexadecyl-2-hydroxyethyl-dimethylammonium dihydrogen phosphate (HHDMA) ligand have been stabilised within the microchannels of a metallic monolith coated with a high-surface area γ-alumina layer. The stainless steel skeleton of the monolith was 3D printed by stereolithography. The washcoating protocol has been optimised in order to maximise the γ-alumina loading without blocking the microchannels. A battery of techniques has been applied to characterise the properties and three-dimensional organisation of the phases within the monolithic reactor from the macro- to the nanoscale including N2 sorption, X-ray diffraction, thermogravimetric analysis, nuclear magnetic resonance and infrared spectroscopies, X-ray tomography, and optical or electron microscopies. Evaluation of the catalyst performance in the flow hydrogenation of acetylenic compounds of different size and functionality demonstrates the high efficiency and stability of the structured catalyst. Particularly, the monolithic reactor retains the intrinsic selective character of the hybrid palladium nanoparticles, even at high temperatures and pressures (T > 343 K and P > 5 bar). This is attributed to the improved isothermicity of the catalyst bed, deriving from the high thermal conductivity of the metallic skeleton of the monolith. Overall, the work provides a general route to prepare monolithic reactors based on Pd-HHDMA nanoparticles, bridging the gap between hybrid nanomaterial and reactor engineering.