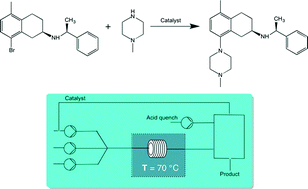

Continuous flow Buchwald–Hartwig amination of a pharmaceutical intermediate

Abstract

A flow process for direct amination of a pharmaceutically relevant substrate using a Pd-NHC based catalyst was demonstrated in a lab-scale mini-plant and in a pilot-scale plant. The lab-scale mini-plant was used to determine catalyst stability under recycling conditions. Results in the mini-plant have shown the maximum space–time yield between the three types of reactor systems: a batch reactor, a mini-plant and a pilot plant. A comprehensive life-cycle assessment study of the synthesis of organometallic catalysts and their impact on the overall LCA of flow vs. batch syntheses was developed. Combined with a simplified economic analysis, the LCA study confirmed the benefits of switching to flow.

Monolith-based 68Ga processing: a new strategy for purification to facilitate direct radiolabelling methods

Abstract

The post-processing of 68Ga generator eluate by means of a novel high capacity cation-exchange silica monolith column has been validated in this work. Quantitative release of a purified 68Ga solution in high concentration can be achieved using weak acidic solutions which can be directly used for chelator or conjugate labelling in an injectable form with improved radiochemical characteristics. The system has the potential to be incorporated in a flow based microfluidic system for dose-on-demand radiotracer synthesis.

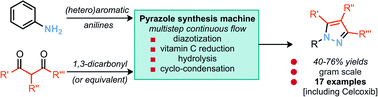

A multistep continuous flow synthesis machine for the preparation of pyrazoles via a metal-free amine-redox process

Abstract

A versatile multistep continuous flow setup is reported for the four-step conversion of anilines into pyrazole products. The synthesis machine incorporates the use of amine-redox chemistry through diazotization and a metal-free vitamin C mediated reduction. The machine can be used for the synthesis of an array of analogues or the scale up of an individual target.